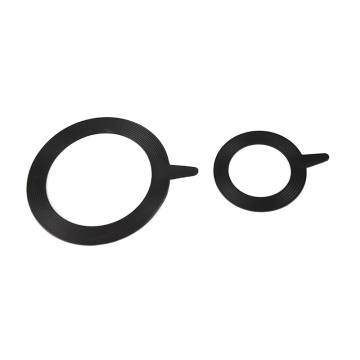

custom keyboard keycaps mechanical

-

$10.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 10000 |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,Express Delivery,DAF,DES,EXW,FAS,FCA,CPT,CIP |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Guangdong,Shenzhen |

Metal keyboards are another type of keyboard, but work in the same way as regular keyboards and have a similar internal structure. The difference is that the metal keyboard, due to its special metal material, has a strong appearance, can achieve riot, dust, waterproof and other ordinary keyboard does not have the function. If you need to customize the keyboard, you can send us the drawing so that we can make a quotation.

What is CNC mechanical keyboard?

CNC machining is a reduction manufacturing process that uses a variety of precision cutting tools to remove raw materials to make parts or products. Advanced software is used to control equipment according to your 3D product design specifications.

Our team of engineers and mechanics program the equipment to optimize cutting time, surface finish, and final tolerances to meet your design specifications. We use CNC machining to manufacture not only parts and prototypes but also mold tools that can be used in our plastic injection molding or pressure die casting services.

* Quick manufacturing * Highly accurate and repeatable

* Suitable for many different kinds of substrates * More strong than 3d printing

* Scalable volumes from one to one-hundred thousand * Economical

CNC customized keyboard processing steps:

1. Prepare your product 3D file

The process starts with engineers using computer-aided design software (CAD) to program a 3D file of the product.

2. Choose the most appropriate material for your prototype

3. Case design and shaping

When the 3D files are ready, the blocks are molded using a CNC machine. First, the program data is uploaded to the CNC machine. Secondly, CNC high-speed machine tools began to shape plain materials according to programming files.

4. First polish

The purpose of painting is to ensure that all surfaces of each part are polished

5. surface treatment

We can provide different types of surface treatment, such as polishing, sandblasting, anodizing, electroplating, powder spraying, painting, UV coating, etc.

6. Changing outfits

We will assemble all parts according to the customer's requirements.

7. Prototype testing

Prototypes are ready for final quality checks before delivery to our customers.

Q&A

Q1: What information do you need for quotation?

You can provide 2D/3D drawings or send your samples to our factory, then we can make them according to your samples.

Q2: Can we sign a confidentiality agreement?

Of course, we never disclose our client's information to anyone else.

Q3: Do you provide samples?

Yes, we can provide you with samples before we order in bulk.

Q4: How do you guarantee the quality?

We have a professional quality control department to ensure quality.

Bergek is a world-class manufacturing service provider in Shenzhen. We got advanced equipment to provide all-around customized products for manufacturers around the world, focusing on CNC machining and sheet metal fabrication.

End: Merchants who need customized products can send drawings to szbergek for quotation

click request quotation

Related Keywords