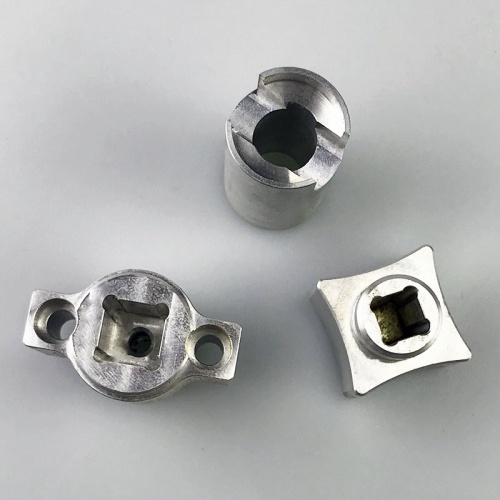

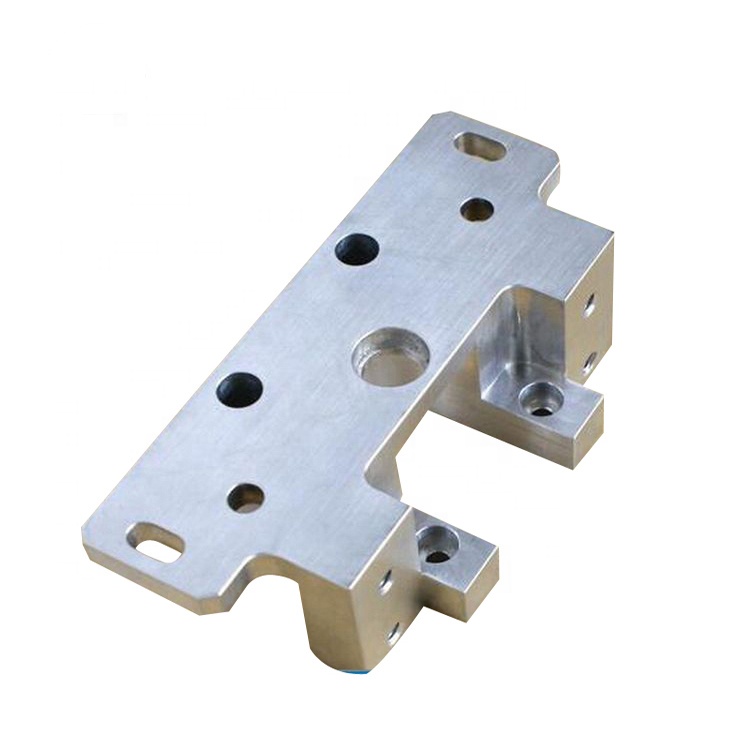

Cnc Part Machining Services Sheet Metal Processing Parts

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T |

| Incoterm: | CFR |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean |

| Port: | Guangdong,Shenzhen |

Quick Details

CNC machining usually refers to precision machining, CNC machining lathes, CNC machining milling machines, CNC machining boring and milling machines, etc

What Are Tolerances?

In short, tolerances are measurements that signify the level of precision needed for a part that you want to manufacture. Specifically, machining tolerances indicate the degree of variation permitted in a part’s final dimensions or measured value.

Machinists measure machining tolerances by numerical values, typically preceded with a ± symbol. For example, you may assign a tolerance of ±0.001″ to a part measuring 2.550 inches in length. This would indicate that the manufactured part would have a variable length measuring between 2.549” and 2.551”. If a part measuring 1.5 inches in height needs a tolerance of ±0.005”, the final part should fall into the range of 1.495” and 1.505” to pass quality inspection.

Specified machining tolerances tell manufacturers and CNC machining services what degree of precision to use when producing a part. The smaller the tolerance—in the manufacturing world this is a tighter tolerance—the more precision required. The larger the tolerance—also called looser—the less precision you need.

Things to Keep in Mind when Choosing Tolerances

One of the key things in determining the right CNC machining tolerances is figuring out at what point a part’s function and performance will be affected by a variation in dimension or size. Some types of parts, like critical components in engines, require a high degree of precision and any lapse in geometric form could have serious consequences. Other types of parts might not require the same degree of precision, and a slightly larger manufacturing deviation will not affect them.

Materials: Aluminum, copper, brass, stainless steel, steel, iron, alloy, zinc etc.

Other Special Materials: Lucite/Nylon/wood/titanium/etc

Surface Treatment: Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc

Tolerance: +/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

Testing equipment: CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge;Marble platform;Roughness measurement

Processing: CNC turning, CNC milling, CNC machining, Grinding, EDM wire cutting

File Formats: Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc.

Service Project: To provide production design, production and technical service, mould development and processing, etc

Dimension: OEM Cnc Machining Service Parts

FAQ

Q1:Where can I get product&price information?

A1:Send us e-mail , we will contact you as we receive your mail.

Q2: How soon can I get samples?

A2: Depending on your specific project, it usually takes 10 to 20 days.

Q3:How to enjoy the OEM services?

A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurement based on your samples to make drawings for machining parts making.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send reports with pictures and videos which show the machining progress.

End: Merchants who need customized products can send drawings to szbergek for quotation, click request quotation

Related Keywords