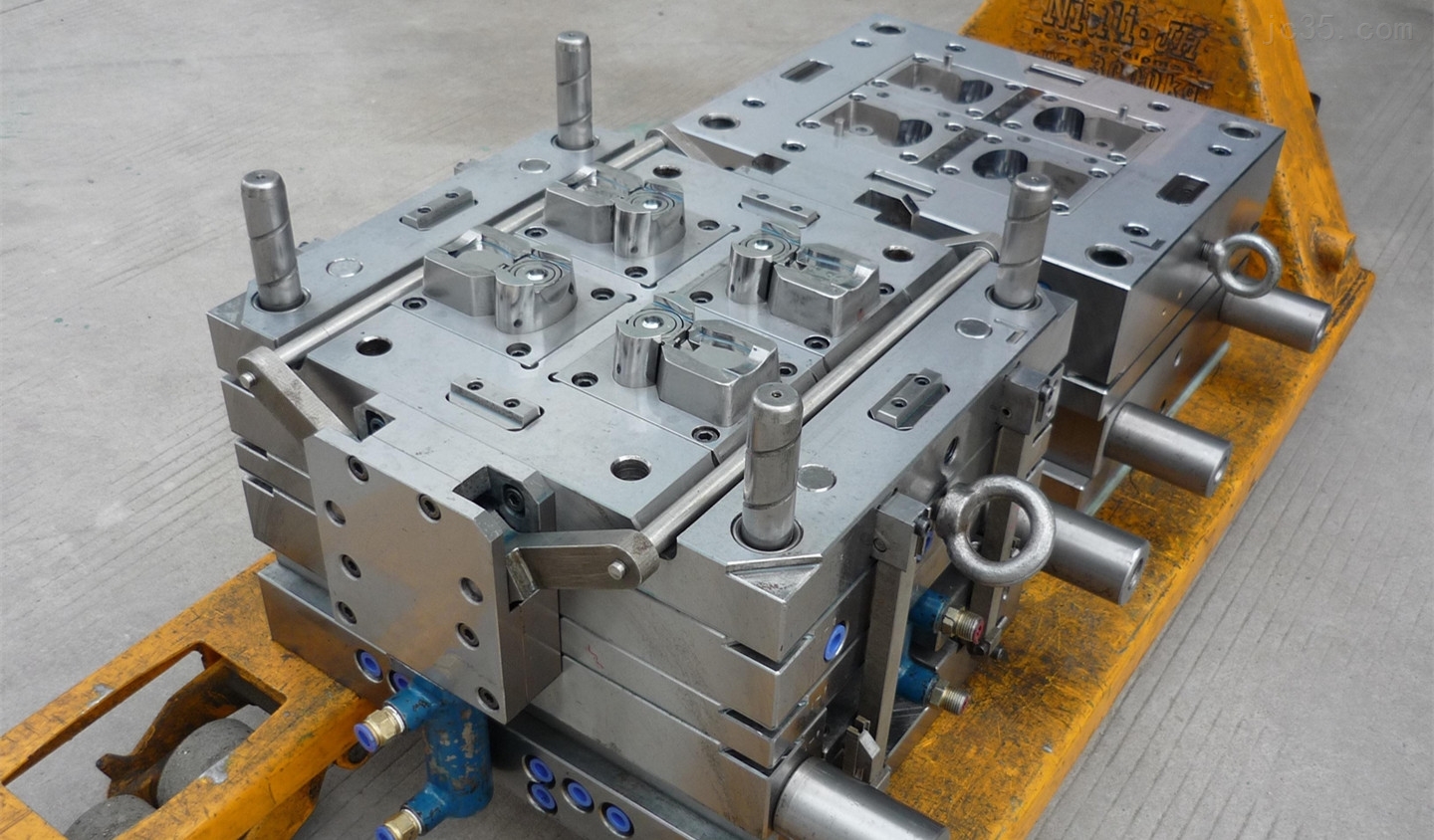

titanium cnc machining parts

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Cutting characteristics of titanium alloy materials:

Some physical and mechanical properties of titanium alloy bring great difficulty to machining. When cutting titanium alloy, the deformation coefficient is small, which increases the sliding friction distance of chips on the rake face and accelerates tool wear. The thermal conductivity of titanium alloy is small, and the heat generated during cutting is not easy to spread out, which is concentrated in a small range near the cutting edge. The elastic modulus of titanium alloy is small, and it is easy to produce bending deformation under the action of radial force during machining, which will cause vibration, increase tool wear and affect the accuracy of parts. Due to the strong chemical affinity of titanium alloy to tool materials, the tool is prone to bond wear under the conditions of high cutting temperature and large cutting force per unit area.

Titanium alloys also have a work hardening trend, so it is very important to remove metals by shear rather than extrusion. In addition, although titanium alloy has high strength, it also has low elastic modulus, which means that compared with other materials, titanium alloy is relatively more elastic and easier to leave the cutting edge (especially in light load cutting). Considering these characteristics of titanium alloy, in order to successfully realize the turning of titanium alloy, the key is to realize the balance of cutting speed, feed rate and cutting depth.

In the actual titanium alloy processing process, many factors that must be considered will be encountered. Based on this, the milling process of titanium alloy will be different from the main machining methods for a long time. The continuous development of two new milling tool solutions and applications has provided new possibilities for titanium alloy milling.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly, and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords