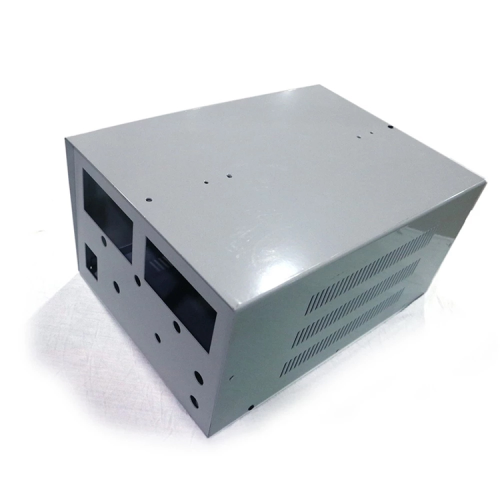

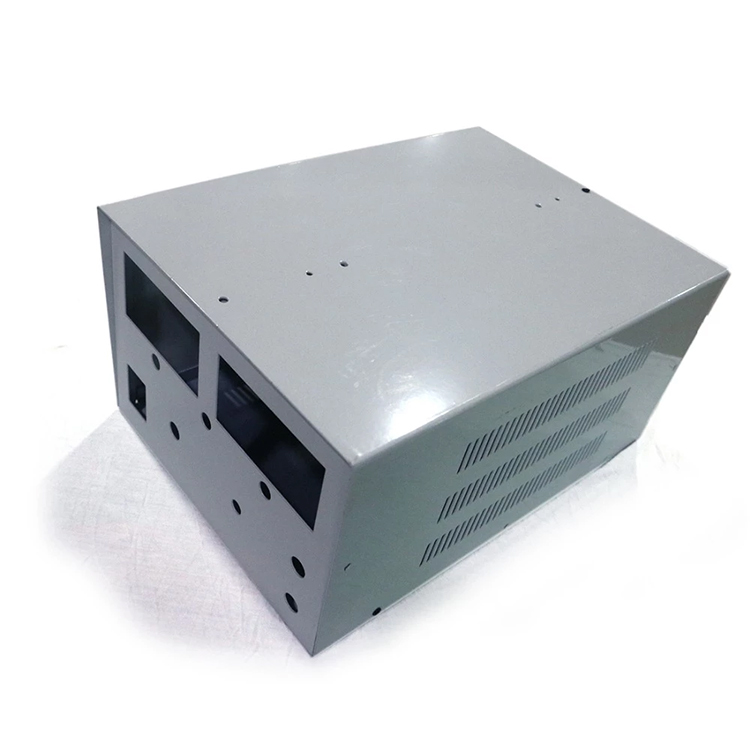

metal sheet metal chassis shell

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

There are a computer case cabinet, TV backplane, car shell, air conditioner shell, terminal integrated case, charging pile box, and so on.

Sheet metal processing method

Sheet metal processing is not thick, the thickness of raw materials is less than 6mm, and the whole process of application is not easy to overload. In the development of sheet metal processing, in order to better ensure the quality of raw materials, cold processing technology will be used to achieve the purpose of manufacturing, capital can only be put into use after cold storage molding. In the whole process of sheet metal processing, it is necessary to go through stamping, cutting, cutting, and other operating steps, so that the processing quality of sheet metal is more in line with specifications.

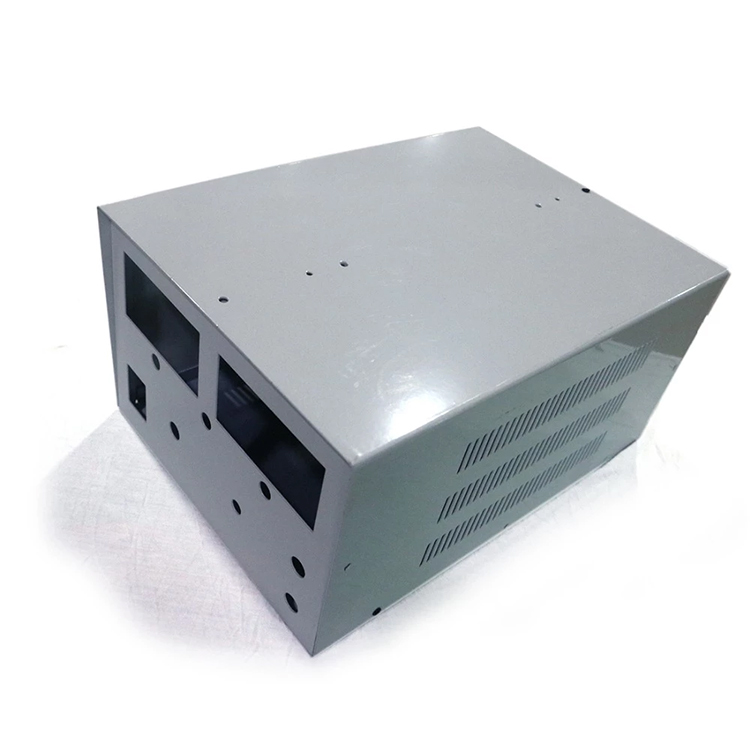

The lightness of the chassis should not only ensure the lightness of the chassis but also ensure the durability of the chassis. This is a very contradictory problem. Using steel plates as raw materials can ensure the robustness and strength of the chassis, but if the steel plate density is large, the strength of the chassis can not be guaranteed sometimes if the aluminum plate density is small. At this time we can process reinforcement on the thin steel plate to plate strength or through aluminum plate bending and other forms of parts strength.

In the whole process of using sheet metal chassis processing, it is necessary to strictly follow the sheet metal processing method, so as to better ensure the quality of sheet metal processing and can standardize the thickness of parts, not easy to produce differences. Now the application scope of sheet metal processing is very common and can be produced according to the specific application requirements, so this processing technology is very convenient and fast. This process is also regarded as a critical operational stage in the manufacture of sheet metal workpieces and immediately jeopardizes the actual results of sheet metal work.

After the sheet metal chassis processing steps, the product has a stronger appearance quality and elegant practical effect. After the installation and application of sheet metal processing, considering the application requirements of the site, the appearance and functional level are not regretful, but also can reduce the processing cost, so that the actual effect of sheet metal processing in the whole application process is more prominent.

Sheet metal raw materials have the advantages of light material and high compressive strength, so sheet metal processing also has such advantages and characteristics. Sheet metal processing, which can control costs for manufacturers, to meet the requirements of field application, is worthy of great development.

Product Details:

According to your drawings (size, material, thickness, processing content, required technology, etc.)

Material: carbon steel, SPCC, SGCC, stainless steel, aluminum, brass, copper, etc

Processing: Laser cutting, precision stamping, bending, CNC punching, grinding, riveting, drilling, welding, and so on

Surface treatment: drawing, polishing, anodizing, powder coating, electroplating, screen printing, sandblasting, etc

Tolerance: ±0.1mm, 100%QC before delivery, can provide quality control table

Size: Accept custom size.

Colors: white, blank, silver, red, gray, Pantone, RAL, etc

Drawing format: DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, draft.

Price terms: EXW, FOB, CIF, DDP, etc

Payment term: Sample: 100% payment before production

Mass production :(50% in advance as deposit, balance before delivery)

Certificate: ISO9001:2015 / SGS

FAQ:

Q1: Are you a factory or a trading company?

A: We are a factory, so we can offer you competitive prices.

Q2: What kind of services do you offer?

A: OEM sheet metal processing, CNC processing, stamping tool manufacturing, etc.

Q3: What information is required for a quotation?

A: In order to quote for you earlier, please provide us with the following information at the time of inquiry.

1. Detailed drawings (STEP,CAD,SOLID Works,DXF,PDF)

2. Material requirements (SUS,SPCC,AL,SECC,SGCC)

3.Surface treatment(powder coating,planting,sand blasting,polishing,oxidization,brushing,etc)

4. Quantity (per order/month/year)

5. Any special requirements or requirements, such as packaging, delivery, labeling, etc.

Q4: What if there are no drawings?

A: Please send your sample to our factory, then we can copy or provide you with a better solution, please send us pictures or sketches with dimensions (thickness, length, height, width), if the order is placed, CAD or 3D files will be made for you.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords