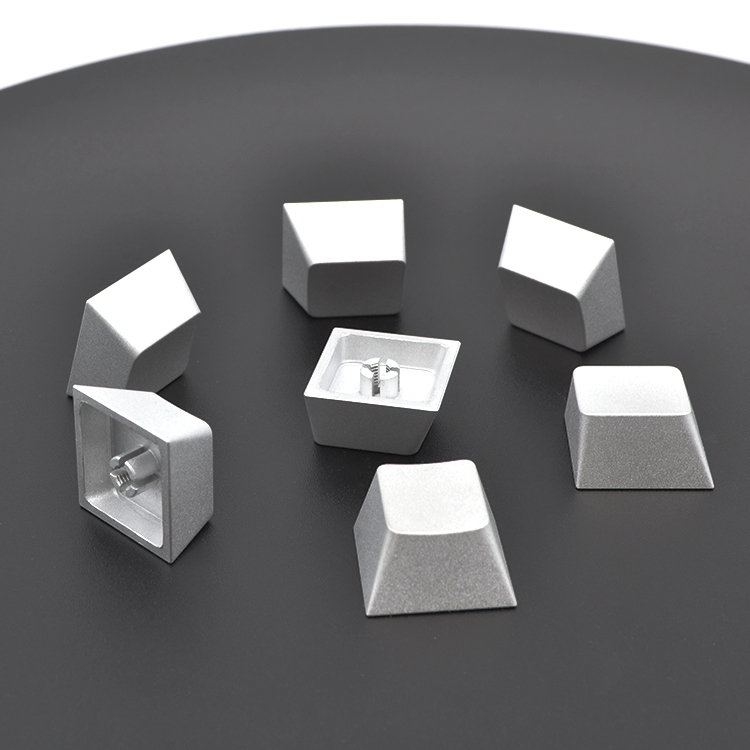

CNC custom keyboard caps

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Laser etching

At present, the most mainstream key cap process is laser etching process. As the name suggests, the laser etching process is to use the laser to burn traces on the key cap. The laser etching process is low-cost and the characters are durable. Because the characters are burned by laser etching, it is basically formed at one time, so it can be completed without other measures. Another reason for the popularity of laser etching process is that it is relatively environmentally friendly, so basically, the output of laser etching key cap is about ten times that of other processes. Laser etching process has the characteristics of low cost and long service life, so it is the most common character process in the keyboard market. Basically, all price range keyboards will see laser etching process keycaps.

screen printing

Screen printing is also a popular technology at present. The principle of screen printing is to cover the special screen on the key cap, in which the character part is hollowed out, and then scrape the screen with ink, so that the handwriting can be printed on the key cap. Although the cost of screen printing is also very low, compared with the laser etching process, the service life of the key cap is much shorter, which is mostly seen on the low-cost thin-film keyboard. Screen printing + UV film coating is also a very common key cap process of film, that is, a layer of UV film coating is covered on the basis of screen printing, and the service life is longer than that of silk screen printing.

Thermal sublimation (including immersion printing)

The thermal sublimation process is quite different from the ordinary ink printing. The thermal sublimation uses not the common liquid dye ink, but the solid resin ink. The solid resin ink will sublimate under high temperature and then penetrate into the key cap, and then coagulate. The thermal sublimation process forms a whole on the surface of the physical layer of the key cap, so it is better in gloss and firmness.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly, and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Related Keywords