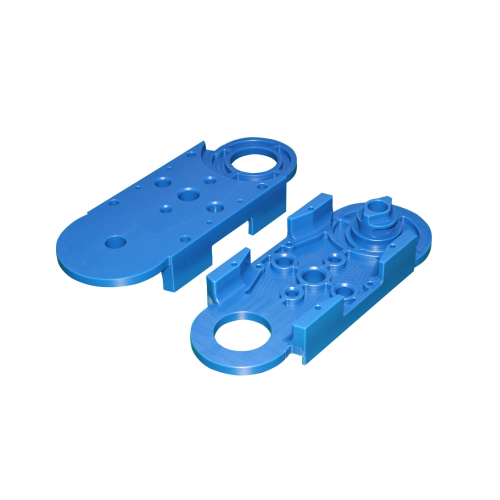

polyurethane injection molding Customized

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Polyurethane molding is the process of fabricating or manufacturing plastic parts by introducing a urethane polymer system into a tool or mold and allowing it to cure. Like any other type of plastic, the excellent processability of polyurethane makes it a very efficient material in the fabrication of common consumer goods and industrial parts.

This process involves the high pressure impingement mixing of two or more reactive liquid components and injected into a closed mold at low pressure. With RIM technology, cycle time of 2 minutes and less have been achieved in production for molding large and thick parts. Principal plastic used is thermopolyurethane (PUR). other material s used are thermoplastic nylon; thermoset polyester and epoxy.

The advantages of the RIM over injection molding include the molding of the parts larger than 10 pounds, they can be made on the production basis using thinner walls because of the lower processing viscosities, or using very thick walls because curing is uniform throughout the part. There are problems associated with this method, however. The lack of the suitable internal release has made the RIM process labor-intensive, but changes are now occurring to significantly reduce or eliminate this problem.

The molded polyurethane faithfully reproduces the surface of the mold and tends to stick to them. Originally the application of the mold-release agents was necessary with each cycle of the RIM technology. After polymerization, if the mold is not covered with the mold-release agent, the part will adhere to the mold, making it difficult to remove from the mold. In view of these occurrences, the mold material should be highly polishable and platable with nickel, this coating has proved to be the most effective in product removal.

Why Choose Bergek

professional custom CNC Machining Parts Manufacturer in China

* Guangdong Aluminum Application Precision Technology Co, Ltd was established in 2012 and has over 10 years experience of in researching. developing and manufacturing CNC Machining Parts

* We have the recognition of famous brand customers all over the world

* Our company has more than 200 professional employees and over 10000 sqm modern factory area

* Our products own many patents and quality system certifications ISO 9001

* Our products own many patents and quality system certifications ISO 9001 is over 250,000 tons, exported to over 120 countries.

Related Keywords