oem injection molding machine

-

$10.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean |

| Port: | Guangdong,Shenzhen |

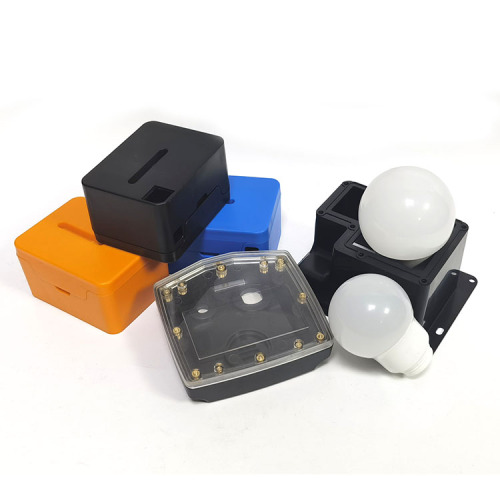

Injection molding can be applied in a very wide range of common kitchen supplies, garbage cans, bowls, buckets, POTS, tableware, electrical equipment shell, hairdryer, vacuum cleaners, food mixers, toy cars, car parts, tables, cosmetic packaging boxes, and other industrial products are injection molding products.

Advantages of injection molding

1, short molding cycle, high production efficiency, easy to realize automation.

2, can be shaped complex shape, precise size, with metal or non-metal inserts of plastic parts.

3, product quality is stable.

4, wide range of adaptation.

The advantages of injection molding process

Plastic parts of the injection molding process mainly include filling - pressure - cooling - demoulding and other four stages, the four stages directly determine the quality of the product molding, and the four stages are a complete continuous process.

Product Details:

Mould material: aluminum, silicone rubber material, plastic material, PC/ABS, ABS, PC, PVC, PA66, POM, or whatever you want

Plastic surface finish: polishing treatment, texture treatment, smooth finish, paint, screen printing, rubber paint, etc

Diagram format: IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.

FAQ

Q1:Where can I get product&price information?

A1:Send us an e-mail, we will contact you as we receive your mail.

Q2: How soon can I get samples?

A2: Depending on your specific project, it usually takes 10 to 20 days.

Q3:How to enjoy the OEM services?

A3:Usually, based on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurements based on your samples to make drawings for machining parts making.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

About us

Bergek is a world-class manufacturing service provider in Shenzhen. We got advanced equipment to provide all-around customized products for manufacturers around the world, focusing on CNC machining and sheet metal fabrication.

End: Merchants who need customized products can send drawings to szbergek for quotation, click request quotation

Related Keywords