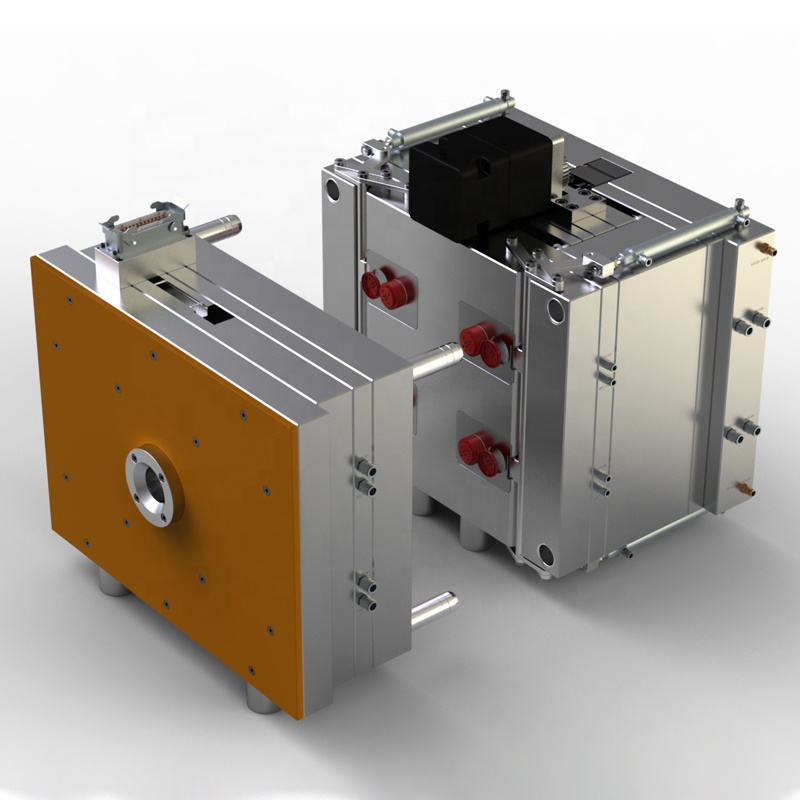

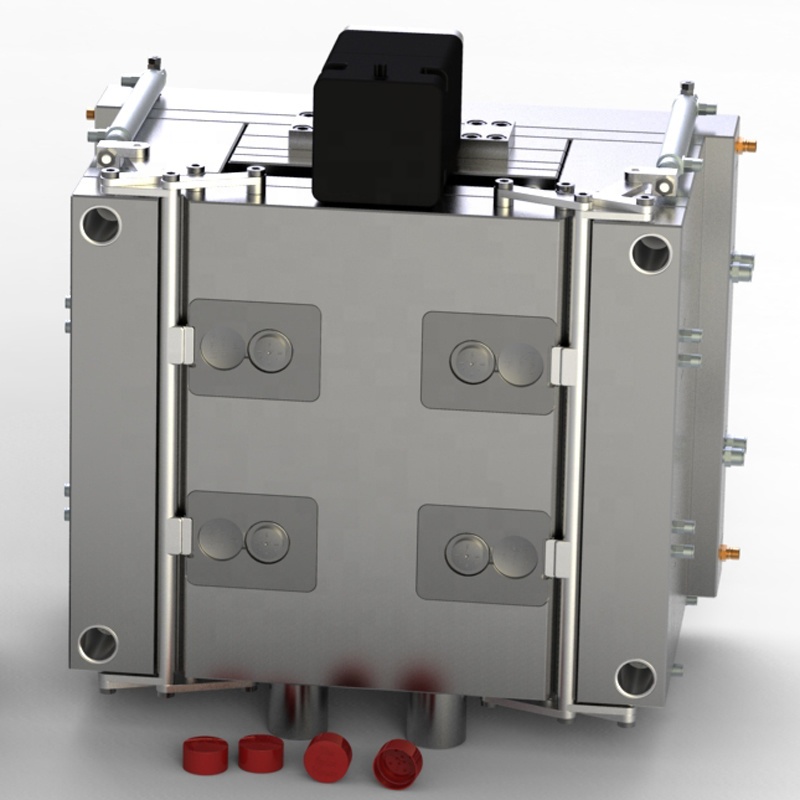

Plastic Injection Mould Service

-

$10.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean |

| Port: | Guangdong,Shenzhen |

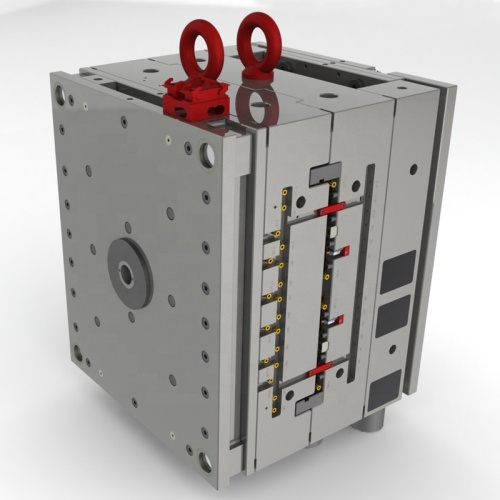

With the development of society and the improvement of people's living standards, people's requirements for the quality of injection mold are becoming higher and higher, and the number of injection mold produced by mold factories is also increasing. In short, an injection mold is a tool for the production of plastic products, mainly used for mass production, injection mold can easily and quickly provide plastic products with complete structure and accurate size. If you need customized injection molding products, you can send us drawings so that we can offer a quotation. Szbergek will introduce injection molding mold-related content to you below.

First, the type of injection mold

Due to a large amount of injection mold used, and the application of different fields, the classification is complicated. The molding characteristics can be divided into a thermosetting injection mold and a thermoplastic injection mold. According to the molding process, it can be divided into transmission mold, blow mold, casting mold, hot forming mold, hot pressing mold, and injection mold.

Two, the application of injection mold

Most plastic products are produced by the production of plastic injection molds, for many companies, injection molds are essential equipment for the production of all kinds of plastic products. The products produced by injection mold have the advantages of light quality, high strength, good toughness, corrosion resistance, good insulation, easy coloring, easy molding, low cost, so it has been widely used and obtained people's love and favor.

Nowadays, these plastic products have entered people's lives and are inseparable from people's production and life. With the rapid development of the plastic industry, plastic products have been greatly promoted and applied in various industrial sectors such as aviation, electronics, machinery, automobile, and daily life. It can be said that plastic parts have been deeply into the various departments of the national economy, the trend of plastic parts has been strengthened, and the emergence of plastic products, in many aspects has become a substitute for metal products. Whether in improving productivity, ensuring product quality, or reducing costs, reduce labor intensity, injection mold has great advantages.

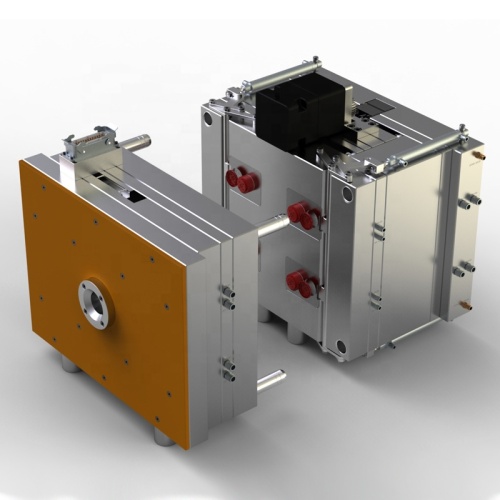

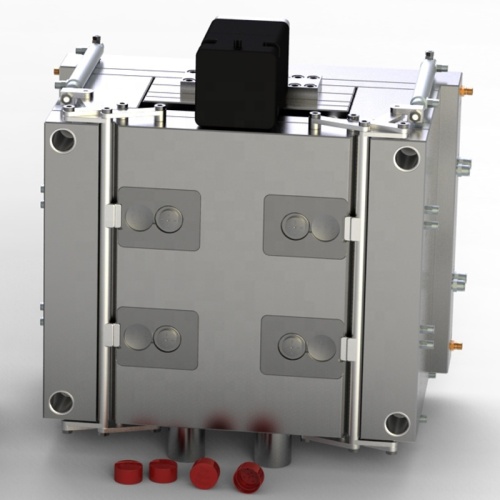

Product introduction

Product Description:ODM plastic injection molding

Plastic Materials:PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc.

Standard:ISO9001:2008

Other materials:Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper...Metal...etc.

Quality:RoSH and SGS standard

Feature:Non marking and Non flash

Size:According to your 2D, 3D Drawing

Color:Quantity,Unit price,Tooling cost,Tooling size:To be discussed

Package:Standard exported Wooden box packed, Fumigation process(upon required)

Mold Building Lead Time:T1, 4-5 weeks, Part measurement report (upon required).

Export Country:Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.:

Experience:13 years experience in plastic injection mold making and plastic prouducts produce.

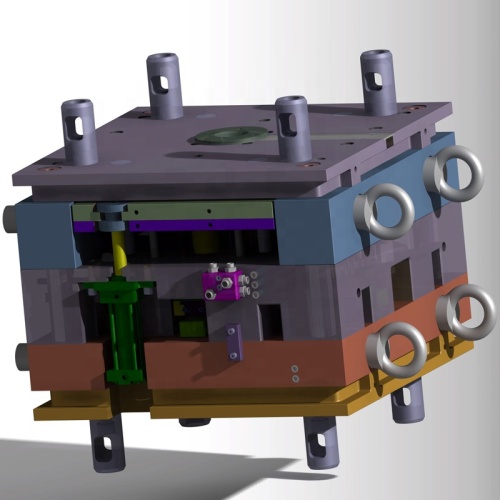

To be discussedIn-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold,

Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc.

Mould Base:Hasco Standard, European Standard, World Standard

Mould Base Material:LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment.

Surface Finish:Texture(MT standard), High gloss polishing

Cavity/Core Steel:P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc.

Hot/ Cold RunnerHUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc.

Mould Life:5,000 to 1,000,000 Shots. (According to your working environment.)

Design & Program Softwares:CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc.

Equipments:High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available.

About us

Bergek is a world-class manufacturing service provider in Shenzhen. We got advanced equipment to provide all-around customized products for manufacturers around the world, focusing on CNC machining and sheet metal fabrication.

End: Merchants who need customized products can send drawings to szbergek for quotation, click request quotation

Related Keywords