Injection molding industry parts

-

$10.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean

- Port:

- guangdong, shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean |

| Port: | guangdong,shenzhen |

In fact, the specific process of injection molding products is to use the injection molding machine to heat the plastic plasticizing melt, and then inject into the cavity of the molding mold molding, after cooling, melt curing demoulding, injection molding machine injection molding products, so what need to pay attention to in processing? szBERGEK is a professional supplier of customized injection molding products. Let's take a look at the matters of injection molding.

Processing:

(1) Injection pressure and speed are too low, barrel temperature and mold temperature are too low, resulting in premature cooling of melting material entering the mold and melting joints.

(2) When the injection pressure and speed are too high, there will be spraying and melting joints.

(3) the speed should be increased, and the backpressure should be increased so that the viscosity of plastic decreases and the density increases.

(4) plastic to dry well, recycled material should be used less, release agent dosage is too much or the quality is not goodwill also appear fusion joints.

(5) Reduce the clamping force, convenient exhaust.

The product description

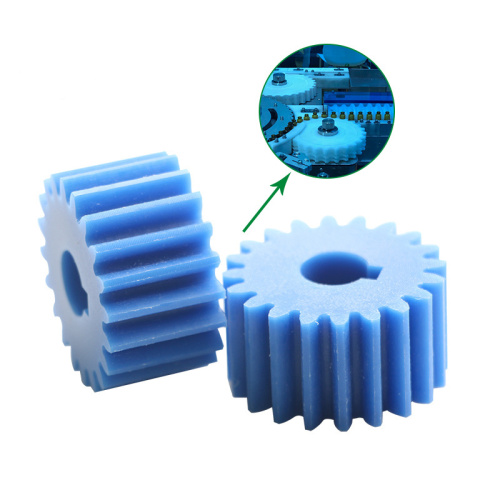

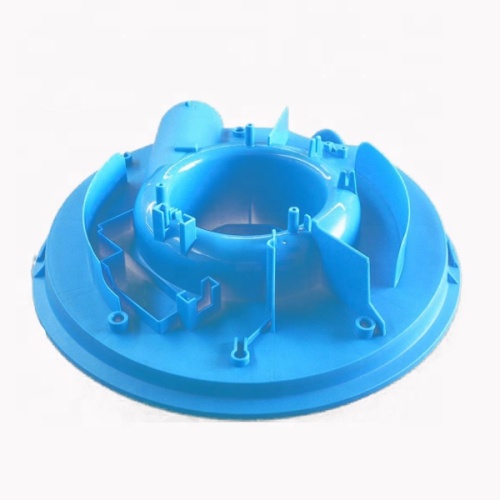

Customized: ABS plastic parts injection molding service and injection molding

Material: ABS, PC/ABS, PP, PC, POM, etc

Certificate: ISO 9001

Drawing format: STP /.step /.igs /.stl /.dwg /.pdf

Color: Custom

Parameters: inches, centimeters, millimeters, etc

Functions: Industrial parts/daily supply/medical supply, etc

Surface treatment: matte finish, ordinary polishing, mirror polishing, texture, electroplating, powder coating (paint), laser engraving, drawing, marble, printing, etc.

Mould material: S136H, 718H, NAK80, P20, H13, etc

Mold precision: SJ/T10628-1995 standard 3 if no special requirements.

Packing: bulk/plastic bag/bubble bag/color box packing.

Sample: available. A cavity sample mold or 3D print.

The above is for reference only, the final actual price depends on your design, material requirements, surface treatment, order quantity, packaging requirements, etc.

Bergek is a world-class manufacturing service provider in Shenzhen. We got advanced equipment to provide all-around customized products for manufacturers around the world, focusing on CNC machining and sheet metal fabrication.

End: Merchants who need customized products can send drawings to szbergek for quotation, click request quotation

Related Keywords