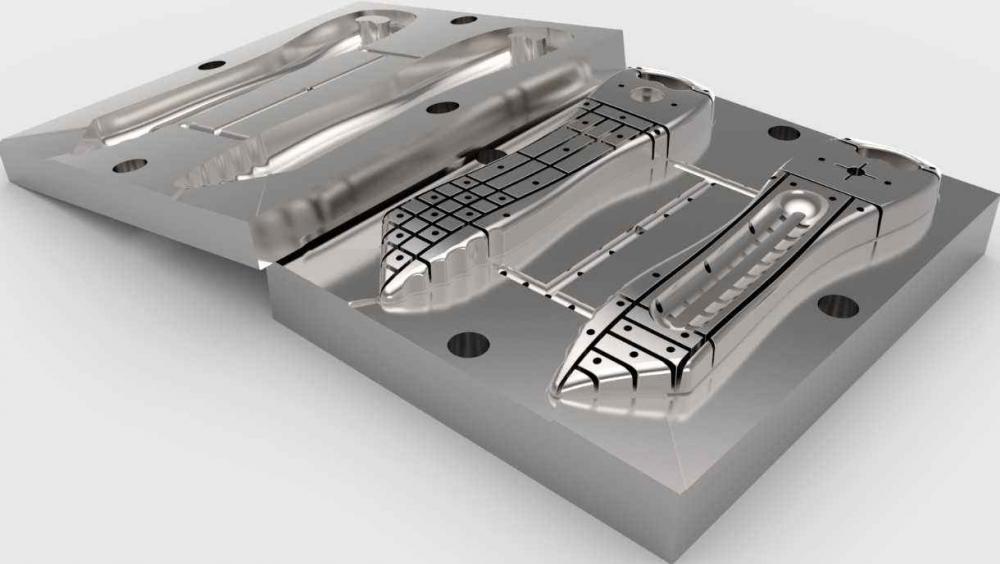

Customized High Precision Injection Mold

-

$9.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- guangdong, shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 10000 |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Certificate: | IS09001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | guangdong,shenzhen |

Product Description

Product Description

The injection molding process is a complex processing process involving mold design, mold manufacturing, raw material characteristics, and raw material pretreatment methods, molding technology, injection molding machine operation, and other factors, and processing environmental conditions, product cooling time, post-processing technology is closely related to the complex processing process.

What are the types of injection molds?

1. Rubber injection molding: Rubber injection molding is a production method that directly infuses the rubber material into the model from the barrel. The advantages of rubber injection molding are: although it is intermittent operation, the molding cycle is short, the production efficiency is high and the preparation process of the embryo material is canceled, the labor intensity is small, and the product quality is excellent.

2. Plastic injection: Plastic injection is a method of plastic products, the molten plastic by pressure injection into plastic products mold, cooling molding to get all kinds of plastic parts. There are special mechanical injection molding machines for injection molding. At present, the most commonly used plastics are polyethylene, polypropylene, ABS, PE, polystyrene, etc.

3. Injection molding: The resulting shape is often the final product and no further processing is required before installation or use as the final product. Many details, such as bumps, ribs, and threads, can be molded in one step.

Product Description:

Molding methods: injection molding, extrusion, compression, blow molding, hot molding

Die life: 300000-1000000shots

Sprue Gate: YUDO runner, Hot runner, Cold number,Pin-point Gate, Submarine gate, etc

Cavity: single or more, according to your requirements

Product material: ABS, PC, POM, PA, PVC, PP, PE, PC + ABS, PMMA, etc

Injection molding Product Case picture:

Product FAQ:

Q1. When can I get the price?

A: We usually quote within 24 hours of receiving your inquiry, if it is urgent please call us or let us know in your email so we can give your inquiry priority.

Q2. What is the delivery time?

A: It depends on the size and complexity of the mold. Usually, the lead time is 25-35 days. If the mold is simple and small, it can be done in 15 days.

Q3. I don't have 3D drawings, how should I start a new project?

A: You can provide samples and we will help complete the 3D graphic design.

Q4. How to ensure product quality before delivery?

A: We focus on high-quality products. We have QC to check the products before each shipment. You can visit our factory or ask a third party to check. Or we can send you a video to show the process.

Q5. How do I pay them?

A: Paypal, Western Union, T/T, L/C are acceptable, so please let us know which is convenient for you.

About us:

Bergek is a world-class manufacturing service provider in Shenzhen. We got advanced equipment to provide all-around customized products for manufacturers around the world, focusing on CNC machining and sheet metal fabrication.

End: Merchants who need customized products can send drawings to szbergek for quotation

click request quotation

Related Keywords

Related Keywords