CNC milling for precision prototyping

-

$8.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- guangdong, shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | guangdong |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,DEQ,DDP,Express Delivery,DAF,DDU,FCA,CPT |

| Transportation: | Ocean,Land,Air,Express |

| Port: | guangdong,shenzhen |

CNC Milling for Precision Prototyping

CNC (Computer Numerical Control) milling is a versatile manufacturing technology used to create complex and accurate parts from a variety of materials, including plastics, metals, and composites. It has revolutionized the way we prototype and manufacture parts, enabling designers and engineers to create high-quality prototypes with unparalleled accuracy and speed.

At its core, CNC milling involves the use of computer-controlled machines that cut and shape materials according to precise instructions. These machines use a variety of cutting tools, including drills, end mills, and lathes, to remove material from a workpiece and create a desired shape. The CNC machine reads instructions from a computer program, known as a G-code, which tells the machine how to move the cutting tool and what shape to cut.

One of the key advantages of CNC milling is its ability to produce highly accurate and repeatable parts. With CNC machines, designers and engineers can create parts with tolerances as small as a few thousandths of an inch, ensuring that each part is consistent and precise. This level of precision is especially important in the prototyping phase, where small deviations can have a significant impact on the final product.

Another benefit of CNC milling is its versatility. CNC machines can work with a wide variety of materials, including metals, plastics, and composites, and can produce parts with complex geometries and shapes. This makes CNC milling an ideal choice for creating prototypes of complex mechanical and electronic components, as well as molds and tooling for manufacturing processes.

CNC milling is also a cost-effective solution for prototyping and small-batch production runs. Traditional manufacturing methods, such as injection molding and die casting, require expensive molds and tooling, making them impractical for small production runs. CNC milling, on the other hand, allows designers and engineers to create high-quality parts without the need for expensive molds or tooling.

In conclusion, CNC milling has revolutionized the way we prototype and manufacture parts. Its ability to produce highly accurate and repeatable parts with complex geometries and shapes makes it an ideal choice for precision prototyping. With CNC milling, designers and engineers can create high-quality prototypes with unparalleled accuracy and speed, all while keeping costs low. If you're looking for a precision prototyping solution, CNC milling should be at the top of your list.

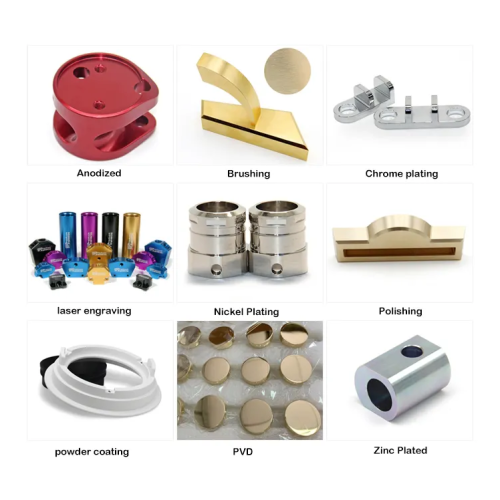

Picture details

Related Keywords