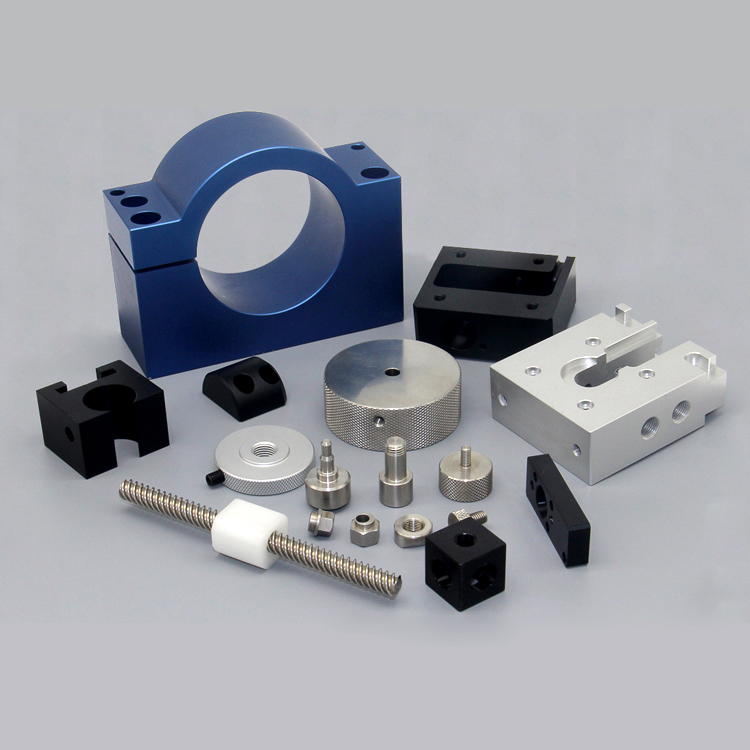

Shenzhen OEM 4 axis custom metal milling

-

$5.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air

- Port:

- Guangdong, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | shenzhen |

|---|---|

| Productivity: | 1000 |

| Supply Ability: | 1000 |

| Payment Type: | T/T,Paypal |

| Incoterm: | CFR,FOB,CIF,EXW,FCA,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Express,Air |

| Port: | Guangdong,Shenzhen |

CNC Milling

Milling is to fix the blank, with high-speed rotation of the milling cutter in the blank, cut out the required shape and features. Conventional milling is mostly used to mill simple shapes/features such as profiles and slots. CNC milling machines can process complex shapes and features. Milling and boring machining center can carry out three-axis or multi-axis milling and boring processing, used for processing, mold, gage, birthyear, thin-wall complex surface, artificial prosthesis, blade, etc. The selection of CNC milling processing content should give full play to the advantages and key role of the CNC milling machines.

Turning to process

The lathe is a part of machining. Lathe processing is mainly used to turn the rotating workpiece turning to a process. Lathes are mainly used for processing shafts, plates, sleeves, and other workpieces with rotary surfaces, and are the most widely used type of machine tool processing in machinery manufacturing and repair factories. Turning is a method of cutting the workpiece on a lathe by rotating the workpiece relative to the tool. The cutting energy in turning is mainly provided by the workpiece rather than the tool. Turning is the most basic and common cutting method, which plays a very important role in production. Turning is suitable for processing rotary surfaces, most of the workpieces with rotary surfaces can be processed by the turning method, such as internal and external cylindrical surfaces, internal and external conical surfaces, end face, groove, thread, and rotary forming surface, etc., the tool is mainly turning tool.

The difference between turning and milling:

Turning is used to process rotary parts, the parts through three chuck clamp on the spindle of the machine tool, and high-speed rotation, and then use the turning knife in accordance with the bus of the rotary body knife, cut out the product shape. The lathe can also carry on the inner hole, thread, flower, and other processing, the latter two for low-speed processing.

Item:Customized Precision CNC Machining Service

Material:

1.Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc.

2.Steel Alloy:l: Carbon Steel / Die Steel / Spring Steel etc.

3.Brass Alloy: 3602 / 2604 / H59 / H62 / etc.

4.Bronze:C51000, C52100,C54400 etc

5.Iron: 1213, 12L14,1215 etc

6.Aluminum Alloy: 5052 /6061/ 6063 / 2017 / 7075 / ADC12/518 etc.

Other Special Materials: Lucite / Nylon / Bakelite / POM / ABS / PP / PC / PE / PEEK / Titanium etc.

Surface treament:Anodize, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving etc.

Tolerance:±0.005mm

Equipment:CNC centre,CNC lathe,General lathe,General Milling, CNC milling, Drilling machine, internal grinder.Cylindrical grinder machine,centerless grinder machine & other equipments.

Standard:Our factory are specialized in the production of Non-standard products.

Our advantages

* Good service

We will get back to you within 1 hour and quote to you within 24 hours. We can manufacture non-standard parts according to your drawings. We offer the best after-sales service.

* Reasonable Price

Our prices are reasonable and competitive if you compare with other manufacturers.

* Perfect quality

We have strict quality control from production to delivery. Our company has strong technical support. We have trained a group of managers who are familiar with product quality and good at modern management concepts.

* Flexible Lead time

When quoting, we will provide you with a suitable delivery date. If the project is urgent, we can set a faster delivery date for free according to the actual situation.

End: Merchants who need customized products can send drawings to szbergek for quotation, click request quotation

FAQ:

Q1:How can I get the quotation?

A1: Send your samples or drawings to us, get the professional quotation immediately!

Q2: Can I get a product sample?

A2: Yes, of course. We will make sample after receiving your payment.And we will take pictures for your check.If you need physical sample, we will send you by freight collect.

Q3: What kind of file can you read?

A3: Various types of 2D or 3D drawings are acceptable,such as JPG, PDF, DWG, DXF,IGS, STEP, X_T, SLDPRT etc.

Q4: What is your way of packing?

A4: Normally we pack goods according to customers' requirement. For reference: wrapping paper, carton box, wooden case, pallet.

Q5: How to deal with the faulty?

A5: Firstly, Our products are produced in strict quality control system and the defective rate will be less than 1%. Secondly, If the parts you received are wrong by our mistakes,we will re-make them for you.Finally,if you received the wrong parts and you don't want us to re-make new parts for you,we can refund you the cost for the order.

Related Keywords