CNC Machining Aluminum Stainless Steel Stamping

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

When CHOOSING HARDWARE material, aluminum alloy and stainless steel are the most commonly used two kinds. Because they are similar in appearance, they are difficult to tell apart, but that doesn't mean they are the same. They are different in many ways. Which is better? This is more concerned about the problem, in fact, the price, hardness, and performance are different.

Aluminum alloy and stainless steel difference

Aluminum alloy and stainless steel products in life are very much, such as our common POTS, basins, doors and Windows, and so on.

Their biggest difference is that the general quality of aluminum alloy is relatively light, and dark color and stainless steel is a relatively heavy and bright color, in addition to their price, hardness, performance, surface, use and so on there are differences.

1. Different prices

Stainless steel is expensive, aluminum is cheap.

2, hardness is different

Aluminum alloy has low density, but high strength, is close to steel, good plasticity; Stainless steel is a nickel-chromium alloy, hardness is higher than aluminum alloy.

3, high-temperature resistance performance is different

Stainless steel can withstand high temperatures, melting point of 1200- 1500 degrees Celsius; Aluminum alloy can not withstand too high temperatures, melting point of 500- 800 degrees Celsius.

4, the surface treatment is different

Stainless steel surface treatment has surface bright treatment, surface whitening treatment, and surface coloring treatment; Aluminum alloy treatment includes electroplating, spraying, anodic oxidation, and so on.

5, industrial applications are different

Stainless steel has heat resistance, oxidation resistance, good formability, and good weldability, which can be used as ultra-high strength materials in the nuclear industry, aviation, and aerospace industry applications; Aluminum alloys are used for processing parts that require good formability but do not require high strength, such as chemical products, food industrial installations and storage containers, printing plates, nameplates, reflective appliances, etc.

Aluminum alloy and stainless steel which good

Because the characteristics of aluminum alloy and stainless steel are not the same, they have their own advantages, so suitable for the use of the scene not the same, it is not good to say which is better, as long as the right place to choose the right material, so that they can fully play out their characteristics.

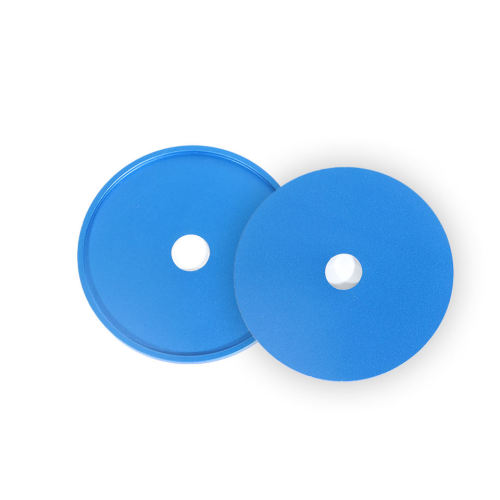

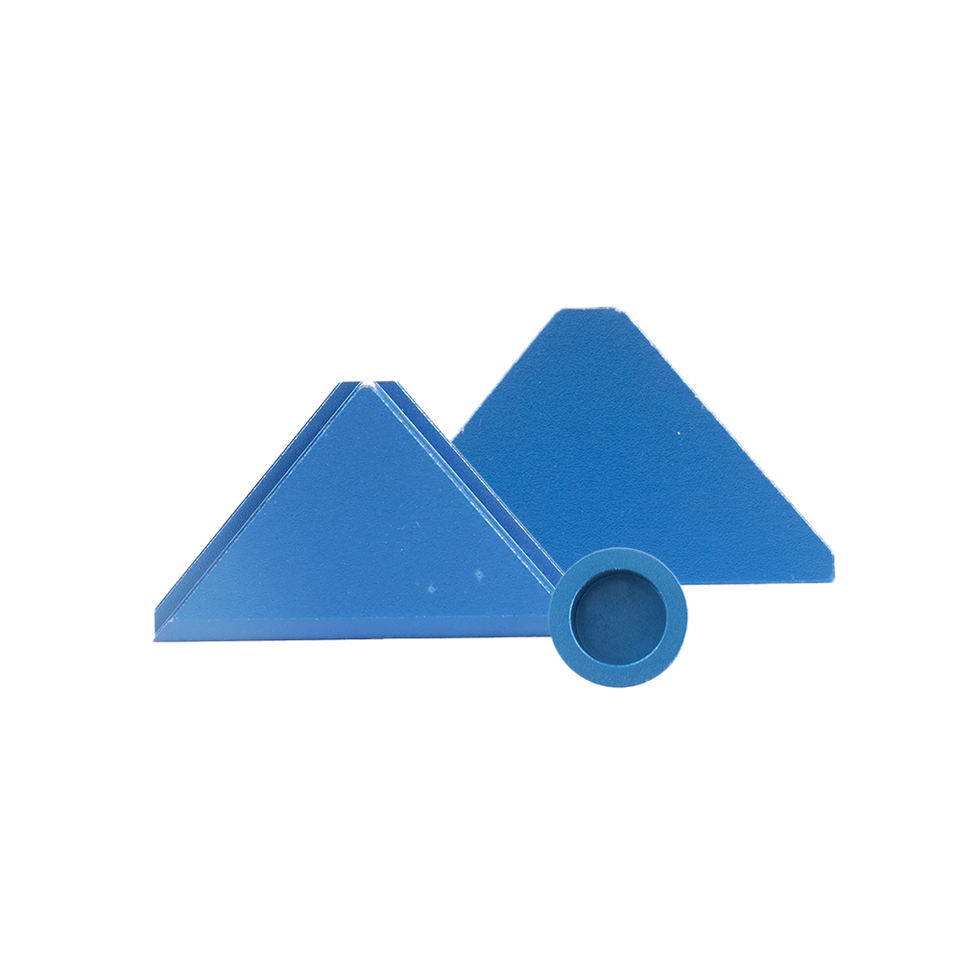

Picture case

Related Keywords