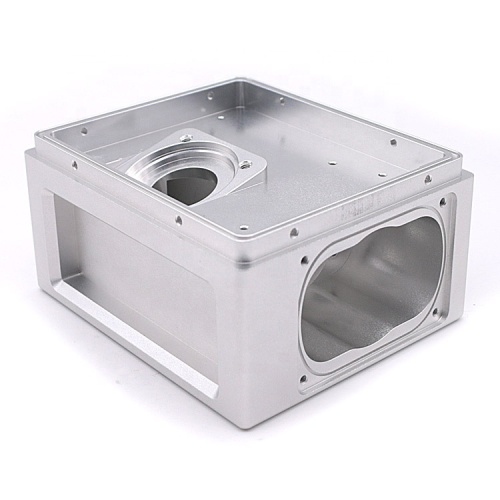

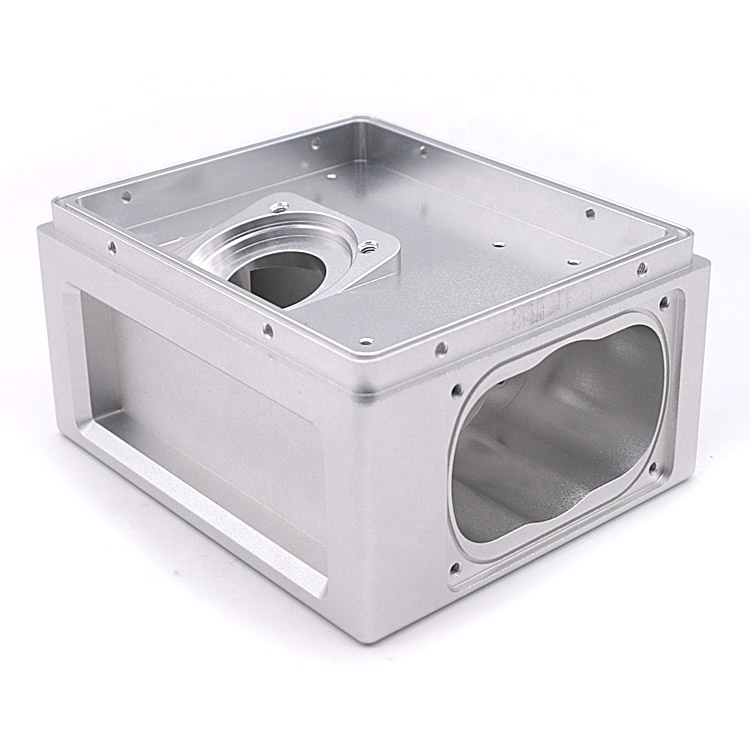

Oem custom metal milling turning

-

$5.30≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SHENZHEN |

|---|---|

| Productivity: | 8000000pcs/month |

| Supply Ability: | 1000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DDP,DDU |

| Certificate: | ISO 9001:2015 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN |

What is milling turning? In the turning process, according to the rotating motion of the workpiece and the linear and curved motion of the tool, the shape and size of the blank are changed, and the workpiece is cut by the rotary tool of the lathe. The cutting machine is mainly used for cutting the workpiece, turning is the most basic, the most commonly used cutting method, playing an important role in production.

The rotating surface is suitable for turning, and most of the rotating surface workpiece can be rotary machined. Internal and external cylindrical surface, cone surface, end face, groove surface, screw, special surface for winding, etc. Lathes are the most widely used metal cutting machine tools, accounting for about 50% of the total number of machine tools. With a drill, hinge, tap, hob, and other tools for rotating workpiece drill, hinge, tap, knurling processing. According to the technical characteristics, layout, and structural characteristics of machine tools, machine tools can be divided into horizontal, floor, vertical, disk, and simulation

Turning is mainly used for processing shaft, disc, set, and other surfaces, suitable for machinery manufacturing and maintenance enterprises, CNC lathes can process complex rotating bodies. Milling is to fix the blank on the high-speed rotating milling cutter to achieve the purpose of machining. At present, the common milling methods mainly include simple contour feature milling and slot milling.

Turning is the processing of tools, cutting machine is the main cutting parts, milling center can be used for milling machines, molds, inspection tools, tires, composite thin wall, three or more axis blades. In numerical control milling, we should make full use of the advantages and functions of numerical control milling and select the processing content.

And we are Oem custom metal milling turning manufacturers, if necessary, you can send drawings to us to provide a quotation.

Product Case picture:

click request quotation

Related Keywords