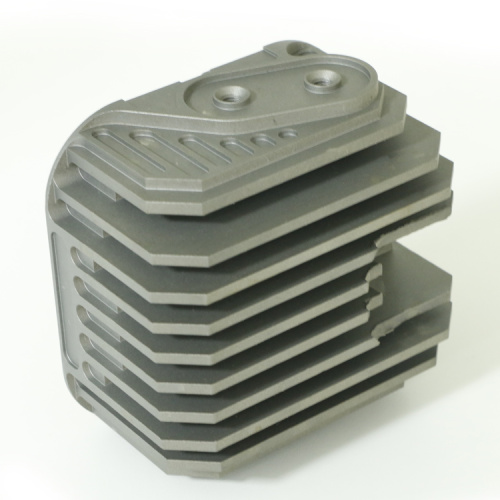

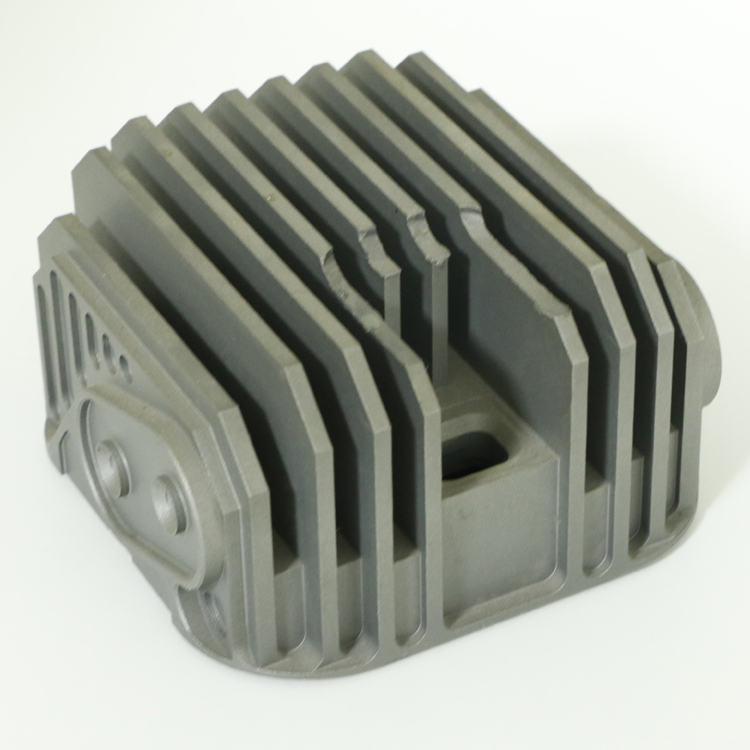

Oem aluminum die casting services

-

$6.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 8000000 |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IOS9001 |

| HS Code: | Non |

| Transportation: | Ocean,Land,Air |

| Port: | ShenZhen |

Aluminum die casting parts surface treatment technology in the market demand a lot, this is because the surface treatment of aluminum die casting parts is not only beautiful, but also can make the performance of aluminum die casting parts better, so, the aluminum die casting surface treatment process is so important, then, what are the surface treatment process?

In fact, the surface treatment process of aluminum alloy die-casting also has many choices. The popular surface treatment process is: passivation, paint baking, sandblasting, powder spraying, shot peening, painting, electroplating, electrophoresis, and so on. Each kind of surface treatment can have a different effect, each kind of effect can have a different experience!

In order to provide a good workpiece surface, the surface treatment has the following points to pay attention to:

1, no oil and water

2, no rust and oxide

3. No adhesive impurities

4, no acid and alkali residue

5, the workpiece surface has a certain roughness

Product Description:

Birthplace: Shenzhen, China

Brand: szbergek

Material: aluminum, zinc, etc

Surface treatment: shot blasting, polishing

Product name: die casting

Process: casting + machining (if required)+ surface treatment

Service: OEM/ODM

About szbergek

In order to provide high quality and competitive price, SZbergek combines various processes of various designs, such as CNC machining, turning, milling, stamping, forging, extrusion, casting, bending, welding, etc. Our commitment is to produce quality products and services on time with friendly customers to increase our business with your company.

At present, our business has grown to the present global coverage to many countries, including the different product areas, such as medical, automotive plumbing and performance parts, agriculture, electronics, electronics, hardware, audio and video, control system, the oil and gas industry, energy, lighting, pressure and filtration system, heating and cooling system.

Our machines include high-speed lathes, CNC lathes, automatic lathes, CNC milling machines, drilling machines, tapping machines, grinding machines, welding machines, pipe benders. To achieve zero defects, we use automatic inspection machines to check dimensional accuracy, consistency, and surface finish.

Our professional team provides one-stop supporting services from design, production, finished product handling, and packaging. We welcome your presence and look forward to your manufacturing opportunities.

FAQ:

Q1: Are you a factory or a trading company?

A: We are a factory, so we can offer you competitive prices.

Q2: What kind of services do you offer?

A: OEM sheet metal processing, CNC processing, stamping tool manufacturing, etc.

Q3: What information is required for a quotation?

A: In order to quote for you earlier, please provide us with the following information at the time of inquiry.

1. Detailed drawings (STEP,CAD,SOLID Works,DXF,PDF)

2. Material requirements (SUS,SPCC,AL,SECC,SGCC)

3.Surface treatment(powder coating,planting,sand blasting,polishing,oxidization,brushing,etc)

4. Quantity (per order/month/year)

5. Any special requirements or requirements, such as packaging, delivery, labeling, etc.

Q4: What if there are no drawings?

A: Please send your sample to our factory, then we can copy or provide you with a better solution, please send us pictures or sketches with dimensions (thickness, length, height, width), if the order is placed, CAD or 3D files will be made for you.

click request quotation

Related Keywords