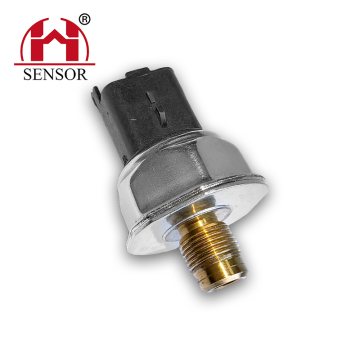

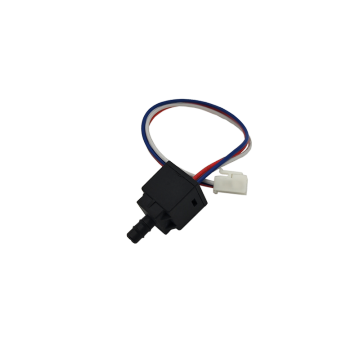

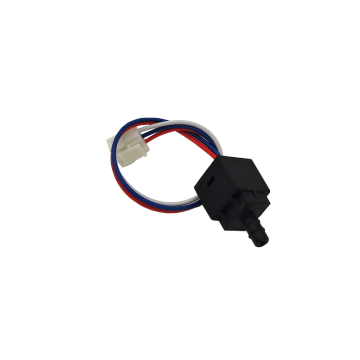

High quality automotive engine sensor

-

$6.00≥1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, s

- Port:

- Jiangmen, Guangzhou, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong |

|---|---|

| Productivity: | 100000pcs/month |

| Supply Ability: | 100000pcs/montjh |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air,s |

| Port: | Jiangmen,Guangzhou,Shenzhen |

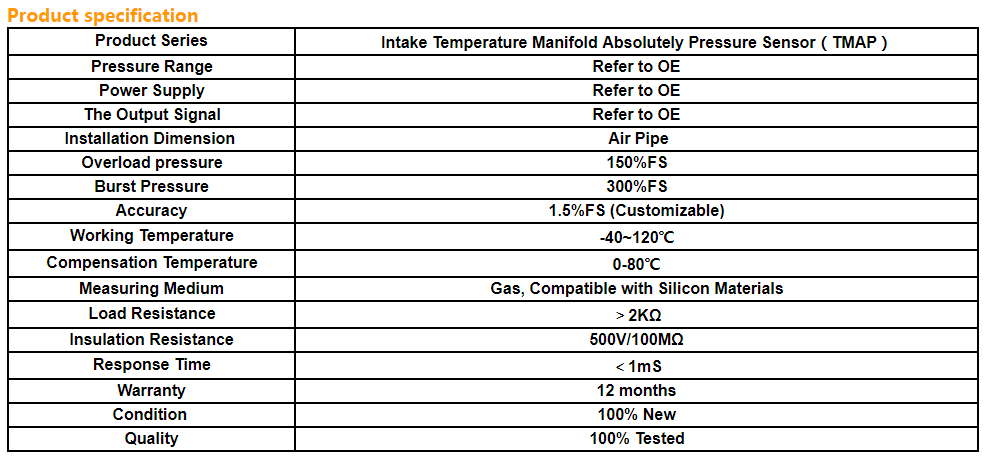

Product description

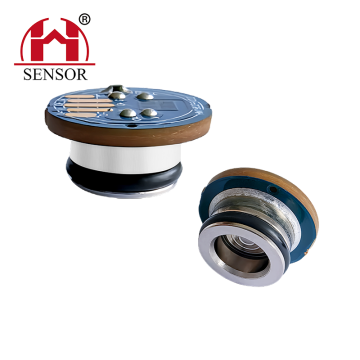

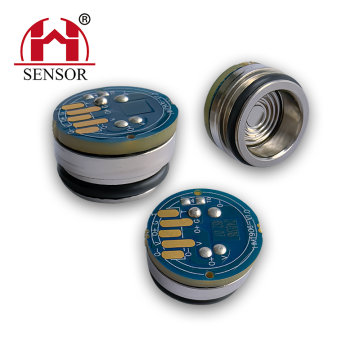

The common faults of vacuum diaphragm manifold absolute pressure sensor include vacuum hose connection, rupture, induction coil rupture, short circuit, etc. When detecting, note that the intake pressure sensor uses 12V power. Therefore, do not unplug the power cable. Check the power supply voltage: turn off the ignition switch, unplug the sensor connector, connect the multimeter to the power cable plug side, and turn on the ignition switch. The voltmeter should show 12V. Otherwise, check whether the power cable is disconnected or short-circuited. Check the output signal voltage: Connect the sensor plug, turn on the ignition switch, connect the red pen of the multimeter to the signal terminal, and tie the black pen to the soldering iron. When increasing the pressure on the vacuum hose, the signal voltage shall be 1.5V; When inhaling the vacuum hose, the voltage should be gradually reduced to 1.5V; When the engine is idle, the voltage should be 0.4V. As the engine speed increases, the output voltage value also increases. Otherwise, the sensor or related cables may be faulty and need to be replaced. Specializing in the manufacture of intake manifold absolute pressure sensor, common rail pressure sensor, injection molding machine special pressure transmitter, urea pressure sensor, air conditioning pressure transmitter, etc.