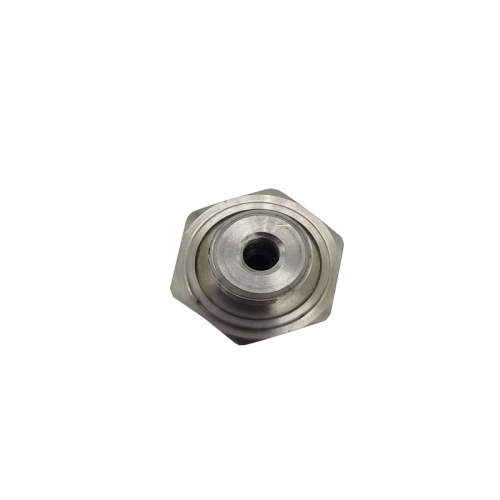

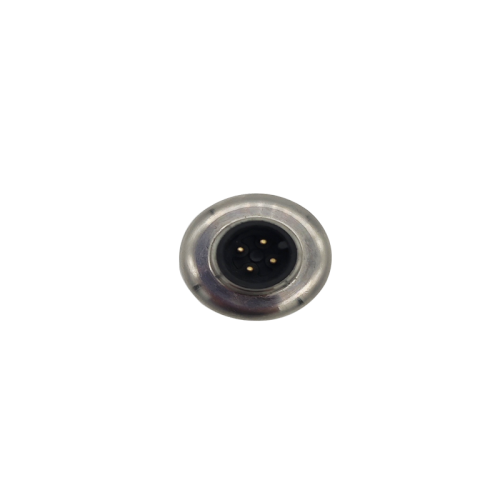

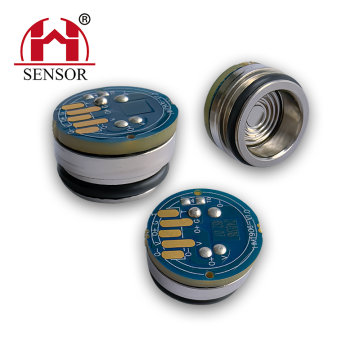

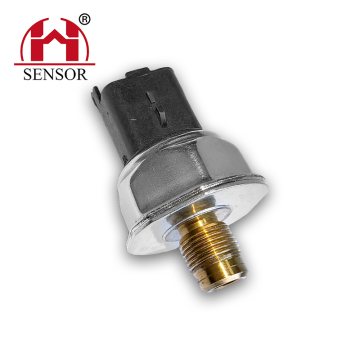

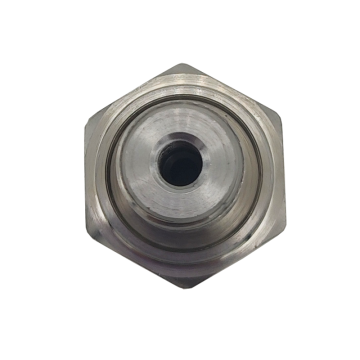

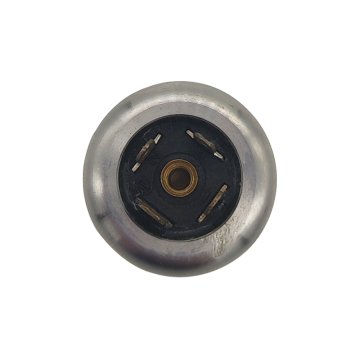

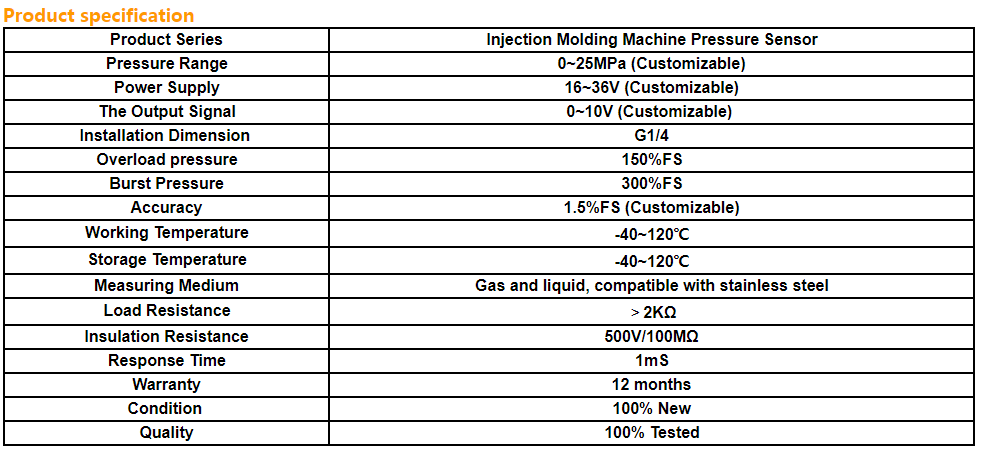

Strong practical injection molding machine pressure sensor

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Transportation:

- Ocean, Air, Land, Express, Others

- Port:

- GuangZhou, JiangMen, ShenZhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100000pieces/Month |

|---|---|

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES |

| Transportation: | Ocean,Air,Land,Express,Others |

| Port: | GuangZhou,JiangMen,ShenZhen |

Product description

Injection molding is one of the most popular mass production techniques in plastic production. About a third of the world's plastic products are processed through injection molding. In the process of injection molding, the measurement of process parameters in the cavity presents some challenges. The first challenge is that the melting pressure usually exceeds 150mpa. The second problem is that the sensing heads are exposed to corrosive and abrasive media at high temperatures and rapidly changing temperatures, often higher than 300°C. During the cooling phase, the accumulation of the frozen layer limits the actual melt pressure measurement. In addition, sensors are usually embedded in molds, which can lead to output variations and deviations in sensor size and shape due to the high temperature of the molds. Therefore, the correct selection of sensors for cavity measurement is a challenging task during this process. Specializing in the manufacture of intake manifold absolute pressure sensor, common rail pressure transmitter, engineering hydraulic sensor, injection molding machine special pressure sensor, urea pressure sensor, air compressor pressure transmitter, etc.

Related Keywords