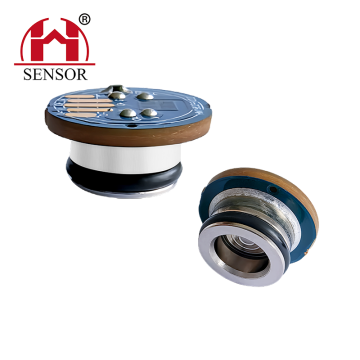

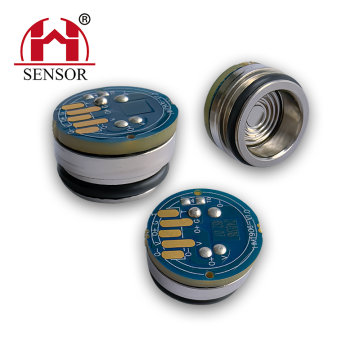

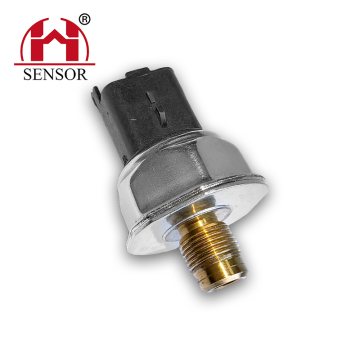

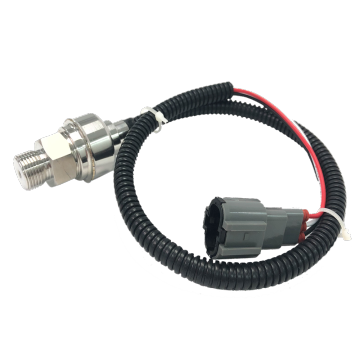

Multifunctional hydraulic pressure sensor

-

$40.00≥200 Piece/Pieces

- Min. Order:

- 200 Piece/Pieces

- Min. Order:

- 200 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Jiangmen, Guangzhou, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong |

|---|---|

| Productivity: | 100000pcs/month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Jiangmen,Guangzhou,Shenzhen |

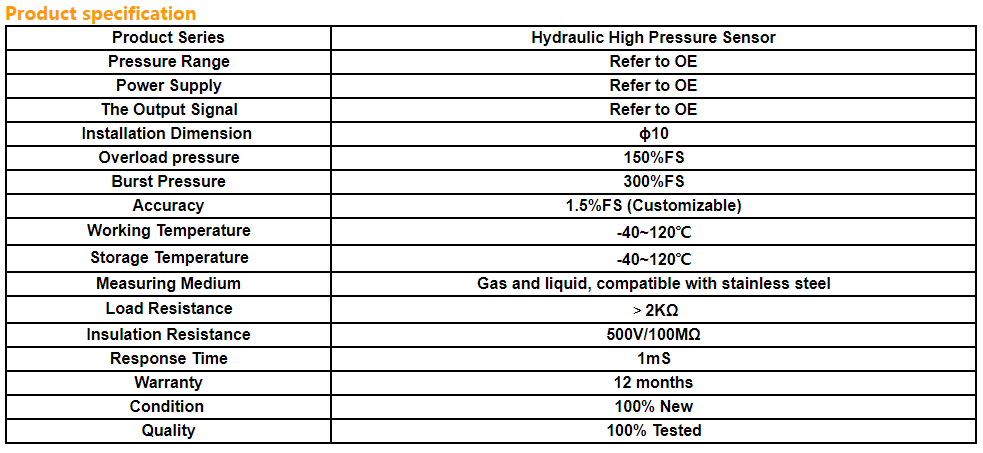

Product description

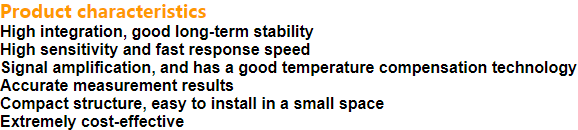

Hydraulic systems tend to be more economical than electrical or mechanical systems because they use fewer parts and are therefore easier to maintain. Because they use fewer parts, it's easier to spot any problems the system might have, making it quicker and easier to fix them when things go wrong. Hydraulic systems also require less maintenance and simple checks, such as changing filters and fluid samples, to ensure everything is working properly. However, electrical and mechanical systems require more maintenance. They usually require lubrication every 80 hours or so of operation, and regular inspection of the power cord and other operational checks. The failure of one component in these systems can lead to the failure of all other components in the chain, resulting in the failure of the entire machine. Hydraulic systems use a high density of incompressible fluid, which is less likely to leak than gas in pneumatic systems. This means they are cheaper to maintain. They do not produce sparks, so they are safer to use and can be used in a wider range of places, such as chemical plants and mines where fire hazards may be present. They are safer overall because they are less likely to catch fire, which may be the case with other systems. Professional manufacturing engineering hydraulic sensor, high precision pressure sensor, water pressure sensor, refrigerant pressure transmitter, air conditioning pressure transmitter, etc.

Related Keywords