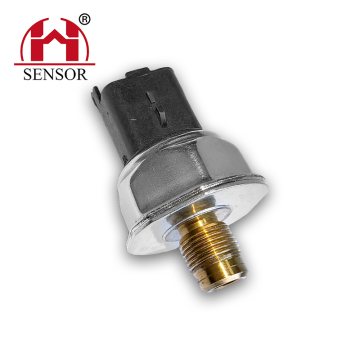

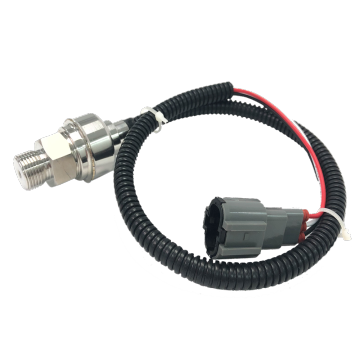

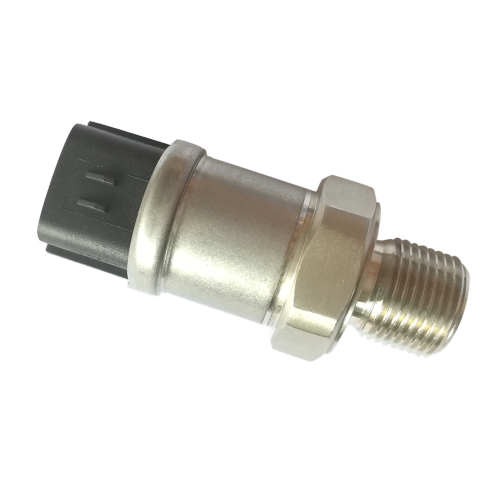

Excavator Parts High Pressure Sensor LC52S00015P1

-

$40.00≥200 Piece/Pieces

- Min. Order:

- 200 Piece/Pieces

- Min. Order:

- 200 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Jiangmen, Guangzhou, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong |

|---|---|

| Productivity: | 100000pcs/month |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Jiangmen,Guangzhou,Shenzhen |

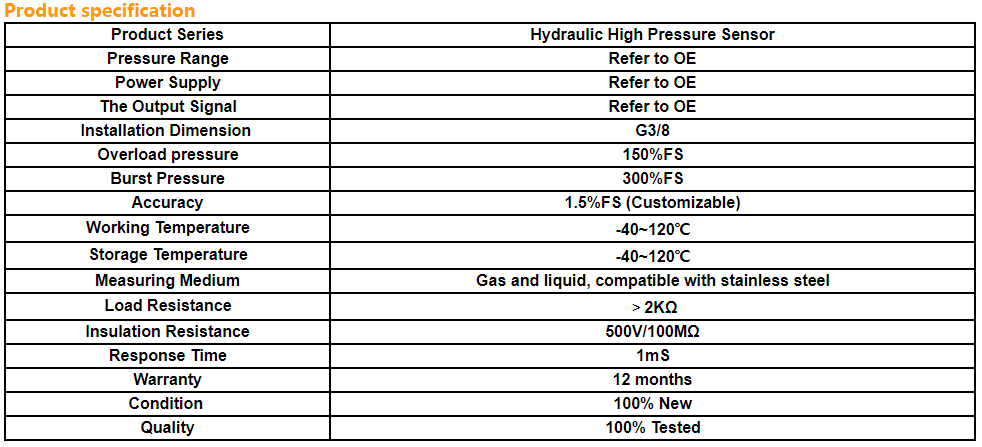

Product description

The method used to test the quality of the pressure sensor depends on the type of sensor and the availability of the test equipment. The following are several commonly used test methods: Multifunctional digital meter test: Use a multifunctional digital meter to connect the input and output lines of the sensor to the meter respectively for testing. This method is suitable for most types of pressure sensors. Multimeter test: Use a multimeter to connect the input and output lines of the sensor to the instrument for testing. This method is suitable for some types of pressure sensors, but may not be suitable for some high-precision sensors. Pressure test bench test: Using the pressure test bench, connect the sensor to the test bench for testing. This method is suitable for high precision and high pressure sensor testing. Specializing in the manufacture of hydraulic high pressure sensors. Thermal shock test: thermal shock test instrument is used to simulate the working state of the sensor in high temperature or low temperature environment, to check whether the sensor is working normally. Before testing, you need to know the specifications, characteristics, and working conditions of the sensor. During the test, check whether the sensor responds properly, whether the cable or connector is damaged, and whether the test result meets specifications. If the sensor is faulty, replace or maintain the sensor in time. Specializing in the manufacture of brake pressure sensor, intake manifold absolute pressure sensor, hydrogen energy pressure sensor, refrigerant pressure transmitter, air conditioning pressure transmitter, etc.

Related Keywords