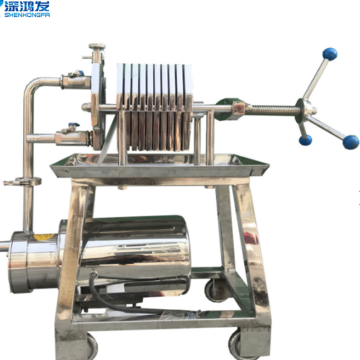

Strong Acid and Alkali Resistant Filter

-

$3500.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500sets/month |

| Supply Ability: | 500sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 842129610.90 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Qingdao,Shanghai |

Acid and Alkali rResistant Stainless Steel Filter Press

Introduction

The filter press uses a special filter medium to apply a certain pressure on the object to make the liquid dialysis out. It is a kind of mechanical equipment commonly used for solid-liquid separation. The material and form of the filter press can be replaced according to different materials and uses. The stainless steel multi-layer filter produced by our company is an advanced filter equipment developed in the 1980s. The whole machine is integrated with the infusion pump, and has the characteristics of compact structure, beautiful appearance, small size, light weight, corrosion resistance, easy maintenance, and long service life. It is widely used by users and is very popular.

(1) Filtration method of stainless steel plate and frame filter

The way of filtrate outflow is clear flow filtration and dark flow filtration.

A. Open flow filtration: a water nozzle is installed on the liquid outlet hole at the bottom of each filter plate, and the filtrate flows out from the water nozzle intuitively.

B. Undercurrent filtration: There is a liquid outlet hole under each filter plate, and the liquid outlet holes of several filter plates are connected to form a liquid outlet channel.

It is discharged from the pipe connected to the liquid outlet hole under the thrust plate.

(2) Washing method of stainless steel plate and frame filter

When the filter cake needs to be washed, there are open flow one-way washing and two-way washing, dark flow one-way washing and two-way washing.

A. Open flow one-way washing means that the washing liquid enters from the washing liquid inlet hole of the thrust plate in turn, passes through the filter cloth and then passes through the filter cake, and flows out from the non-porous filter plate. At this time, the liquid outlet nozzle of the porous plate is closed State, the outlet nozzle of the non-porous plate is open.

B. Open flow two-way washing means that the lotion enters the holes on both sides above the thrust plate and washes twice successively, that is, the lotion is washed from one side first and then from the other side. The outlet of the lotion is opposite to the inlet. Angular direction, so it is also called two-way cross washing.

C. Undercurrent unidirectional flow washing is that the washing liquid enters the porous plate from the washing liquid inlet hole of the thrust plate in turn, passes through the filter cloth and then passes through the filter cake, and flows out from the non-porous filter plate.

D. Undercurrent two-way washing means that the washing liquid is washed twice successively from the two washing liquid inlet holes on both sides above the stop plate, that is, the washing is washed from one side first, and then from the other side. The outlet of the washing liquid is diagonal direction, so it is also called undercurrent two-way cross washing.

(3) Filter cloth:

filter cloth is a main filter medium. The selection and use of filter cloth has a decisive effect on the filtration effect. When selecting, the appropriate filter cloth should be selected according to the pH value of the filter material, solid particle size and other factors. Material and pore size to ensure low filtration cost and high filtration efficiency. When using, ensure that the filter cloth is flat and not discounted, and the pore size is unimpeded.

Related Keywords