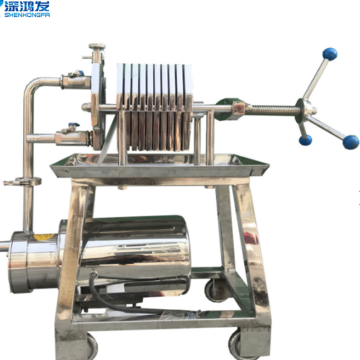

Filter Press for Solid-liquid Separation in Suspension

-

$4000.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Qingdao, Shenzhen, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500sets/month |

| Supply Ability: | 500sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910.90 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Qingdao,Shenzhen,Shanghai |

Pressure filters for solid-liquid separation of various suspensions

Stainless steel multi-layer filter working principle and structural features:

When the stainless steel multilayer Filter is working, it is pressurized and sealed for filtration. There is no loss of liquid material, and the liquid clarity is high. It can also customize a multi-stage filter device according to user needs. Save space and improve filtration accuracy. All the sealing parts of this machine are made of silicone rubber sealing ring, which is high temperature resistant, non-toxic, non-leakage and good sealing.The suspension is pumped into each closed filter chamber of the filter. Under the action of pressure, the filtrate permeates the filter layer and filter membrane or other materials, and is discharged through the membrane outlet, and the filter residue is left in the plate frame to form a filter cake.This stainless steel filter press is suitable for solid-liquid separation of various suspensions, and has a wide range of applications. It is suitable for medicine, food, chemical industry, environmental protection, water treatment, electronic weaving, and electroplating.

This machine can also make a special automatic return device according to the user's requirements. When the pump stops rotating, open the return valve, and all sediments will be automatically discharged (with exhaust function), and at the same time, use clean water to recoil from the return pipe, which is very convenient.

(1) High filtration precision, uniform filter element pore size

(2) Small filtration resistance, large flux, strong pollution interception ability and long service life.

(3) The filter element material has high cleanliness and no pollution to the filter medium.

(4) Resistant to acid, alkali and other chemical solvents.

(5) High strength, high temperature resistance, and the filter element is not easily deformed.

(6) Low price, low operating cost, easy to clean, and replaceable filter element.

Related Keywords