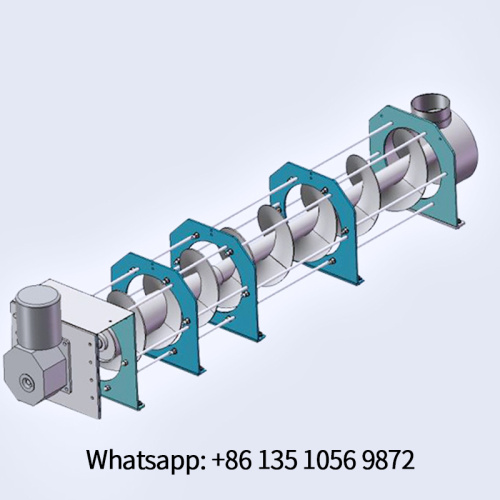

Multi Disk Type Sewage Sludge Dewatering Screw Press

-

$3650.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land

- Port:

- Qingdao, Tianjin, Shenzhen

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Made in China |

|---|---|

| Productivity: | 1000/m |

| Supply Ability: | 1000/m |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910 |

| Transportation: | Ocean,Land |

| Port: | Qingdao,Tianjin,Shenzhen |

Product Description

Product Description

1. Prepare the slurry: Mix the material to be filtered with water or other liquids to create a slurry. The slurry should be well-mixed and free of large particles.

2. Load the slurry: Open the inlet valve and pour the slurry into the screw Press Filter. Make sure the slurry is evenly distributed across the filter.

3. Start the machine: Turn on the power to the screw Filter Press Machine and engage the motor. The screw will begin to turn and move the slurry through the filter.

4. Adjust the pressure: Adjust the pressure of the screw filter press to achieve the desired filtration rate. This can be done by adjusting the speed of the screw or the pressure of the hydraulic system.

5. Collect the filtrate: The filtrate will be collected in a separate container or tank. Make sure to monitor the level of the filtrate and empty the container as needed.

6. Remove the Filter Press Cake: Once the filtration is complete, the Filter Presses cake can be removed from the filter. This can be done manually or with the help of a scraper or conveyor belt.

7. Clean the Flter Press: After use, clean the screw filter press thoroughly to remove any remaining slurry or filter cake. This will help prolong the life of the machine and ensure it operates efficiently for future use.

2. Load the slurry: Open the inlet valve and pour the slurry into the screw Press Filter. Make sure the slurry is evenly distributed across the filter.

3. Start the machine: Turn on the power to the screw Filter Press Machine and engage the motor. The screw will begin to turn and move the slurry through the filter.

4. Adjust the pressure: Adjust the pressure of the screw filter press to achieve the desired filtration rate. This can be done by adjusting the speed of the screw or the pressure of the hydraulic system.

5. Collect the filtrate: The filtrate will be collected in a separate container or tank. Make sure to monitor the level of the filtrate and empty the container as needed.

6. Remove the Filter Press Cake: Once the filtration is complete, the Filter Presses cake can be removed from the filter. This can be done manually or with the help of a scraper or conveyor belt.

7. Clean the Flter Press: After use, clean the screw filter press thoroughly to remove any remaining slurry or filter cake. This will help prolong the life of the machine and ensure it operates efficiently for future use.

Related Keywords

Related Keywords

You May Also Like

You May Also Like