Dehydration Machine for Oily Sludge Treatment

-

$5000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 100/month |

| Payment Type: | T/T,D/P,L/C,Paypal,D/A |

| Incoterm: | CIF,EXW,CFR,FOB |

| Certificate: | ce rohs |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land |

Dehydration Machine for Oily Sludge Treatment

Product Description

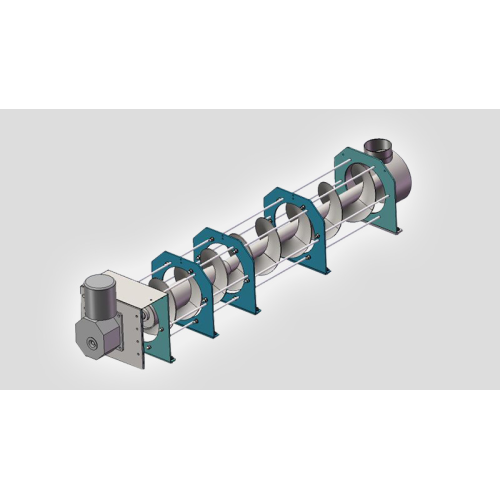

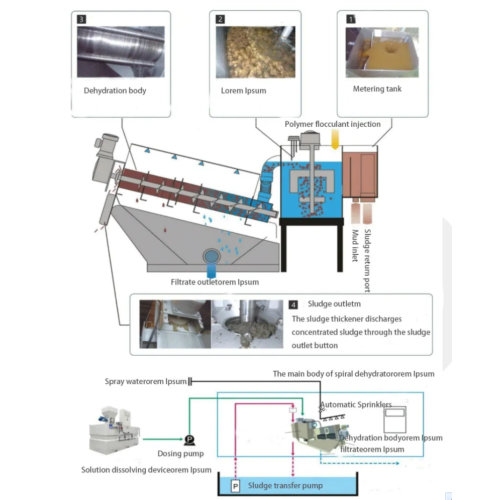

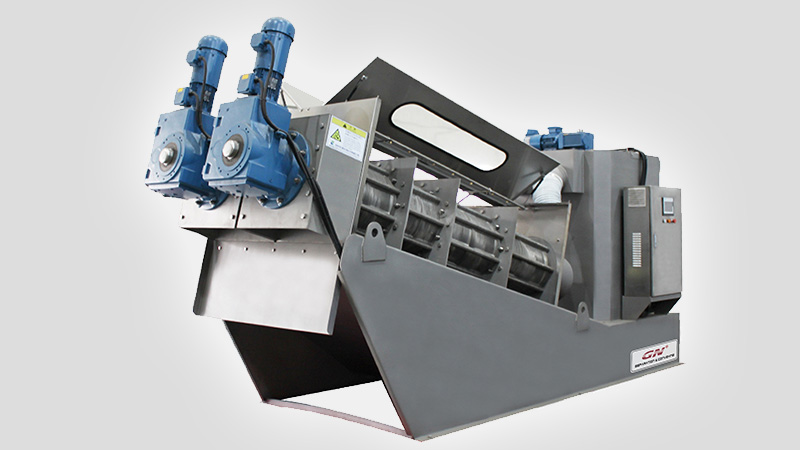

Multi-disc screw press (Hereinafter referred to as MDS) is a new generation of sludge dewatering machine, a screw type sludge dewatering press having more advantages than belt press, centrifuge, plate-and-frame filter press, etc. It features clog-free, wide range of applications, power saving, fully automatic control, low running cost, high resistance to oily sludge, simple operation & maintenance, small footprint, etc. MDS can be widely used in Municipal sewage, food, slaughtering breeding, printing and dyeing, oil chemical industry, paper making, leather, pharmaceutical and other industries of sludge dewatering.Meanwhile, the unique self-cleaning mechanism and stainless steel structure enables MDS to be ideal to dewater oily sludge, which easily causes clogging and is difficult to treat with other types of dewatering equipment.

| Specifications | |||

|

Main Parameters |

Capacity | DS-kg/hr | 180-300 DS-kg/hr |

| Size | mm | L 3605×W1690×H1600 | |

| Power | kW | 1.95 | |

|

Motor |

Gearbox | Brand |

SEW, BAUER, SUMITOMO, NISSEI |

| Protection | Certificates & IP | UL,CE, Water proof(IP65) CCC | |

| Screw Shaft | Treatment | SUS316L, Tungsten carbide coating | |

|

Control Cabinet |

Electrical Components | Brand | Schneider, Omron, Siemens |

| Solenoid Valve | Brand | US, ASCO | |

| Spray System | Brand | Japan Origin, H.IKEUCHI | |

Model Selection

|

Model |

WAS Sludge & Chemical Precipitated Sludge (Thin Sludge) |

Dissolved Air Flotation Sludge |

Mixed Raw Sludge Aerobic Digested Sludge & Sewage Sludge |

||

| Sludge Concentration (TS) |

0.2% |

1% |

2% |

5% |

3% |

| MDS 051 |

~0.4 kg-DS/hr (0.2 m³/hr) |

~0.6 kg-DS/hr (0.06 m³/hr) |

~2 kg-DS/hr (0.1 m³/hr) |

~4 kg-DS/hr (0.08 m³/hr) |

~5 kg-DS/hr (0.16 m³/hr) |

| MDS 101 |

~2 kg-DS/hr (1.0 m³/hr) |

~3 kg-DS/hr (0.3 m³/hr) |

~5 kg-DS/hr (0.25 m³/hr) |

~10 kg-DS/hr (0.2 m³/hr) |

~13 kg-DS/hr (0.43 m³/hr) |

| MDS 131 |

~4 kg-DS/hr (2.0 m³/hr) |

~6 kg-DS/hr (0.6 m³/hr) |

~10 kg-DS/hr (0.5 m³/hr) |

~20 kg-DS/hr (0.4 m³/hr) |

~26 kg-DS/hr (0.87 m³/hr) |

| MDS 132 |

~8 kg-DS/hr (4.0 m³/hr) |

~12 kg-DS/hr (1.2 m³/hr) |

~20 kg-DS/hr (1.0 m³/hr) |

~40 kg-DS/hr (0.8 m³/hr) |

~52 kg-DS/hr (1.73 m³/hr) |

| MDS 202 |

~16 kg-DS/hr (8.0 m³/hr) |

~24 kg-DS/hr (2.4 m³/hr) |

~40 kg-DS/hr (2.0 m³/hr) |

~80 kg-DS/hr (1.6 m³/hr) |

~104 kg-DS/hr (3.47 m³/hr) |

| MDS 311 |

~20 kg-DS/hr (10 m³/hr) |

~30 kg-DS/hr (3.0 m³/hr) |

~50 kg-DS/hr (2.5 m³/hr) |

~100 kg-DS/hr (2.0 m³/hr) |

~130 kg-DS/hr (4.33 m³/hr) |

| MDS 312 |

~40 kg-DS/hr (20 m³/hr) |

~60 kg-DS/hr (6.0 m³/hr) |

~100 kg-DS/hr (5.0 m³/hr) |

~200 kg-DS/hr (4.0 m³/hr) |

~260 kg-DS/hr (8.67 m³/hr) |

| MDS 313 |

~60 kg-DS/hr (30 m³/hr) |

~90 kg-DS/hr (9.0 m³/hr) |

~150 kg-DS/hr (7.5 m³/hr) |

~300 kg-DS/hr (6.0 m³/hr) |

~390 kg-DS/hr (13 m³/hr) |

| MDS 412 |

~80 kg-DS/hr (40 m³/hr) |

~120 kg-DS/hr (12 m³/hr) |

~200 kg-DS/hr (10 m³/hr) |

~400 kg-DS/hr (8.0 m³/hr) |

~520 kg-DS/hr (17.3 m³/hr) |

| MDS 413 |

~120 kg-DS/hr (60 m³/hr) |

~180 kg-DS/hr (18 m³/hr) |

~300 kg-DS/hr (15 m³/hr) |

~600 kg-DS/hr (12 m³/hr) |

~780 kg-DS/hr (26 m³/hr) |

Our Advantages

(1) Hongfa sludge dewatering machine is of unique dewatering structure with fixed and moving rings. It has many advantages over other dewatering machines such as plate and frame filter press, belt filter press and decanter centrifuge, especially for power and rinsing water consumption and labor cost saving. Below is a comparison table among them.

(2) High resistence to oily sludge

The self-cleaning mechanism and stainless steel structure enables MDS to be ideal to dewater oily sludge, which easily cause clogging and is difficult to treat with other types of dewatering equipment like belt filter press.

(3) Clog-free -- saving rinsing water -- saving cost

Due to the rotation of helical axis, the moving rings begin detaching from the fixed rings while continuously starting the

self-cleaning process. As a result, the ubiquitous clogging is avoided with the unique structure. Therefore, it can handle oily sludge without any trouble while separating the water from the sludge easily. In addition, there is no need to add large quantity of rinsing water, thus MDS can saving the cost.

(4) Saving energy -- low power consumption

MDS works by the machine's internal pressure and needs no large scale integrations like rollers. It saves energy and water and has very minimal noise because of low running speed (2-4 r/min). The average unit power consumption is only 0.1-0.01 kwh/kg-Ds (1/8 of Belt Press and 1/20 of Centrifuge).

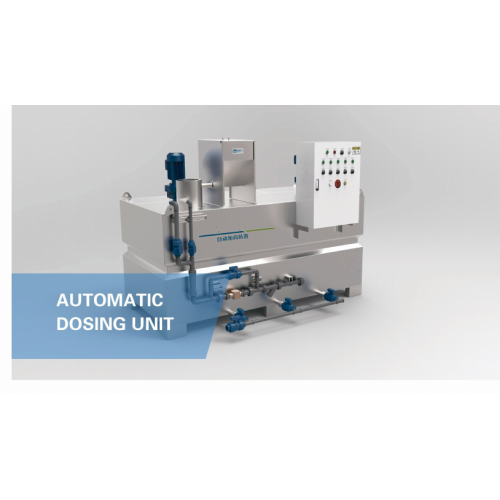

(5) Fully automatic control -- saving labor cost

There are no easily blocked pieces such as belt and filtration pore in MDS. Combining with the auto control system, the machine runs very safely and simply and can be programmed according to the requirement of the users. It can operate automatically for 24 hours, unmanned.

(6) Small footprint -- saving the construction investment of dewatering room

With the smart design, MDS dewatering press can be installed in places where placement would not be possible with other technologies.

(7) No thickeners -- saving the capital investment and costs on other auxiliary equipment

MDS can treat sludge in aeration tank and secondary sedimentation tank without setting sludge thickeners. Therefore, this can decrease the total investment and costs on mixers, air compressors, flushing pumps and other auxiliary equipment.

Dewater Principle

The initial section of dewatering drum is the Thickening Zone,where the solid-liquid separating process takes place and where the filtrate will also be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, hence increasing its internal pressure. At the end, the End Plate further increases the pressure, so as to discharge dry sludge cake.The initial section of dewatering drum is the Thickening Zone,where the solid-liquid separating process takes place and where the filtrate will also be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, hence increasing its internal pressure. At the end, the End Plate further increases the pressure, so as to discharge dry sludge cake.

Product Display

Our company

Shenzhen Hongfa Environmental Protection Equipment CO., LTD is an environmental protection company, specialized in mechanisms, environmental engineering and other related science. With research center in Japan, we have factory and office in China. .Hongfa specializes in the design, engineering, supply and installation of domestic and commercial water, waste water and sewage treatment systems, gas pollution control, and other environmental engineering products. Our company possesses complete sets of process design, equipment supply, constructions, and technology innovation. Overall, we are highly qualified in delivering turnkey and BOT projects for any industry. We have abundant experience in the treatment of industrial, domestic and commercial hazard wastewater.Hongfa is staffed with local and overseas professionals with more than 15 years of acquired technical expertise and experience, offering various technologies and allied services. Our company works closely with the top 10 universities and scientific institutes to keep our cutting-edge technology and transform science and technology into productivity. Our company also works with the government, and is authorized as the liaison office of Yixing government to perform technology cooperation with foreign countries.

Packing & Delivery

Related Keywords