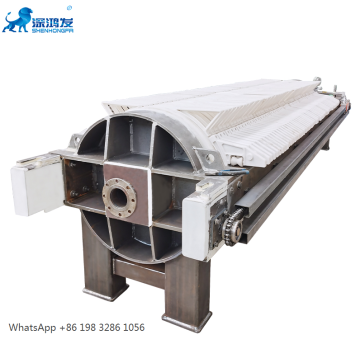

High Pressure Ceramic Clay Round Filter Press Machine

-

$2890.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land

- Port:

- Qingdao, Tianjin, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Made in China |

|---|---|

| Productivity: | 1000/m |

| Supply Ability: | 1000/m |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910 |

| Transportation: | Ocean,Land |

| Port: | Qingdao,Tianjin,Shenzhen |

What's the round high pressure filter press?

A round high pressure filter press is a type of filter press that uses a circular plate and frame design to filter and separate solids from liquids. It operates under high pressure, typically between 100 and 225 psi, to force the liquid through the filter media and separate the solids. The round design allows for more efficient use of space and easier handling of the filter plates. This type of filter press is commonly used in industries such as chemical, pharmaceutical, and food processing.

1. Prepare the filter press by assembling the plates and frames according to the manufacturer's instructions.

2. Place the filter cloth on each plate, making sure it is evenly distributed and free of wrinkles.

3. Close the filter press and tighten the bolts to create a seal.

4. Connect the inlet and outlet pipes to the appropriate ports on the filter press.

5. Fill the filter press with the slurry or liquid to be filtered.

6. Turn on the pump and apply pressure to the filter press until the desired pressure is reached.