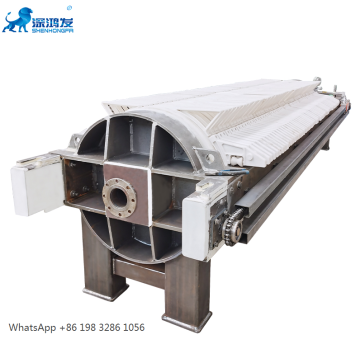

Filter Press for stone wastewater Treatment

-

$6500.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzehen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 200sets/month |

| Supply Ability: | 200sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | CFR,FOB,CIF,EXW,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910.01 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzehen,Qingdao,Shanghai |

How do I select filter press?

Most enterprises will produce a large amount of wastewater and sludge during the reprocessing process, and the stone industry is no exception. At present, the application of stone at home and abroad is very extensive, and it is one of the important raw materials for construction and decoration. Because a large amount of water is needed in the process of cutting stones to achieve the effect of cooling, a large amount of mud water will be generated in this process. If it is discharged directly without mud dehydration treatment, it will cause pollution and damage to the environment. The emergence of high-pressure circular filter press is undoubtedly the best environmental protection equipment for stone wastewater treatment. The advantage of the high-pressure circular filter press is that it has a strong filtration pressure, and the maximum filtration pressure can reach 25Mpa. Then, for example, the stone industry often needs to separate the solid and liquid for some difficult-to-filter materials, and it needs to match the filter press equipment with strong filtration pressure. The high-pressure circular filter press is their best choice.

Round high pressure filter press is widely used in stone mill mud dehydration, electroplating sludge dehydration, urban sludge dehydration, leather sludge dehydration, coal washing sludge dehydration, mine sludge dehydration, ceramic raw material dehydration, steel plant sludge dehydration and so on. This machine can be favored by so many industries, inseparable from its following advantages:

1. Large processing capacity

2. Strong adaptability to sludge viscosity

3. Low comprehensive energy consumption

4. High degree of automation

5. Good operating environment

6. Ideal production efficiency

Related Keywords