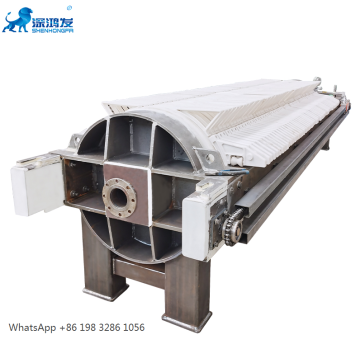

Automatic Filter Presses For Kaolin Clay Production

-

$7500.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 200sets/month |

| Supply Ability: | 200sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212937.91 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Tianjin,Shanghai |

What does filter press do?

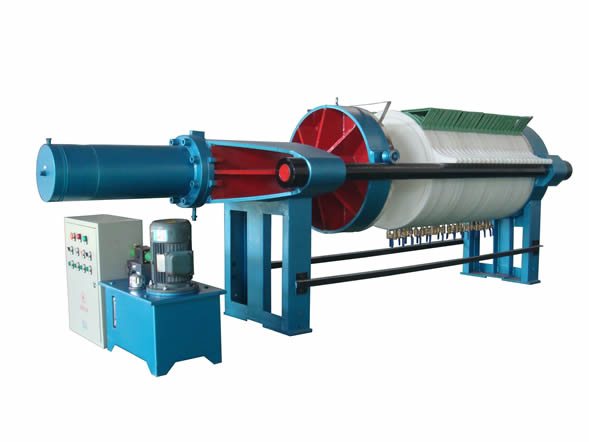

The circular high-pressure filter press is a box-type filter press with automatic pulling plate, which is an environmentally friendly mechanical device for solid-liquid separation. It is made of polymer material, which has the characteristics of light weight, high pressure resistance and good sealing performance. The difference of the circular filter press is that the filter plate is circular, and the circular filter plate is made of high-strength and high-toughness polyethylene material, which makes it have a high compressive strength; the filter chamber adopts a linear seal, In this way, the sealing performance of the machine is good, and it is also resistant to high pressure. Because of its strong pressure resistance and good sealing performance, this machine has a very good filtering effect for materials with high fineness and high viscosity that are difficult to filter, especially suitable for kaolin, ceramic mud, cutting fluid, grinding fluid and other industries.

Design concept and characteristics of round filter plate:

The round filter plate structure of the filter press by setting the honeycomb frame and the second support column, can improve the strength of the filter plate, avoid the filter plate because the pressure is too large to cause damage, pressure performance is more stable, by setting a plurality of convex column, convex column between the formation of water channel, easy to flow to the second through hole, by setting the first through hole and cavity, The water flows into the cavity through the first pass hole and then collects through the outlet hole. The strength of the core plate can be improved by setting the first support column inside the cavity. The fluorocarbon coating can avoid corrosive substances in the sewage to corroded the filter plate and extend the service life of the filter plate. The round filter plate can not only avoid the wear of the ring frame, but also play the role of anti-slip by setting the elastic protective pad on the ring frame.

Related Keywords