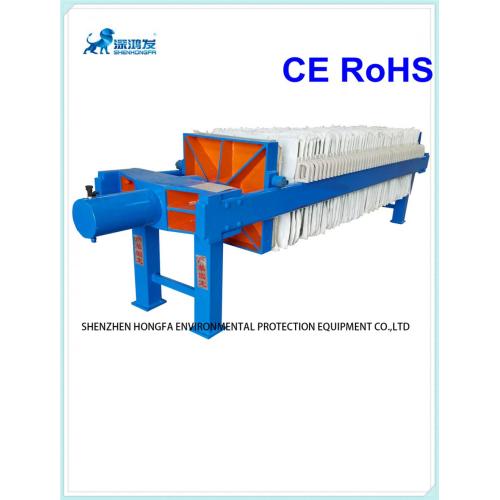

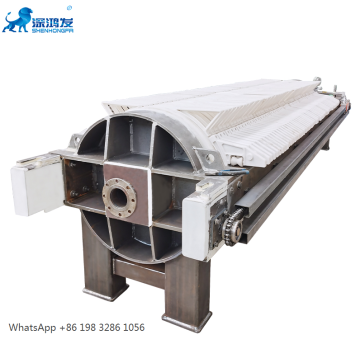

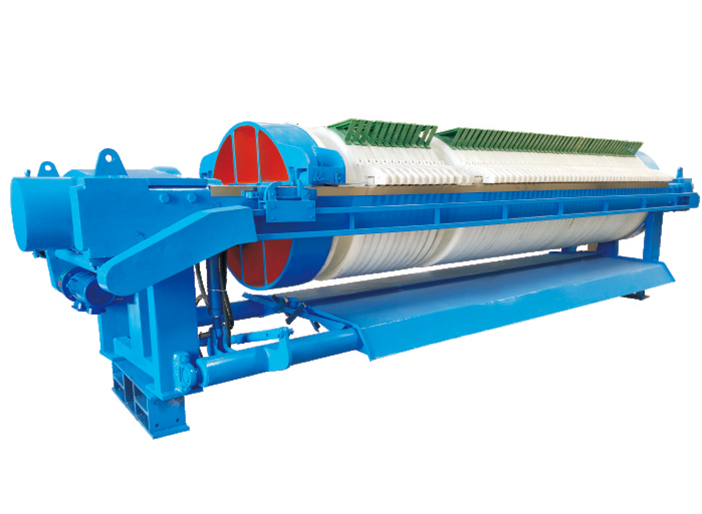

Sludge Dewatering Circular Plate Filter Press Machine

-

$6500.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, TIANJIN, Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | CHINA |

|---|---|

| Productivity: | 300sets/month |

| Supply Ability: | 300sets/month |

| Payment Type: | T/T,Paypal,L/C |

| Incoterm: | FOB,CIF,EXW,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910.90 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,TIANJIN,Shanghai |

Product Description

Product Description

How is filter press calculated?

The main difference between a circular high-pressure filter press and a square filter press is the shape of the filter plate, and its basic structure and working principle are similar to other filter presses. The circular filter press, like the box or plate-and-frame filter press, is a solid-liquid separation device that pressurizes the filter object through a specific medium. Just combining the needs of some specific industries, the square filter plate is improved to a circular filter plate equipment to make it more stable and tighter. In addition, this type of filter press also has the characteristics of high feed pressure and low moisture content of the filter cake, and is widely used in activated soil, ceramics, stone waste water, kaolin, building materials and other industries.

Filtration method of filter press

The way the filtrate flows out is clear flow filtration and dark flow filtration.

A. Open flow filtration: the outlet hole at the bottom of each filter plate is equipped with a water nozzle, and the filtrate flows out from the nozzle intuitively.

B. Undercurrent filtration: the bottom of each filter plate is provided with a liquid outlet channel hole, and the liquid outlet holes of several filter plates are connected to form a liquid outlet channel, which is discharged by a pipeline connected with the liquid outlet holes below the thrust plate.

A. Open flow filtration: the outlet hole at the bottom of each filter plate is equipped with a water nozzle, and the filtrate flows out from the nozzle intuitively.

B. Undercurrent filtration: the bottom of each filter plate is provided with a liquid outlet channel hole, and the liquid outlet holes of several filter plates are connected to form a liquid outlet channel, which is discharged by a pipeline connected with the liquid outlet holes below the thrust plate.

Related Keywords

Related Keywords

Sludge Dewatering Filter Presses , XMY800 Round Plate Filter Press , Filter Press Machinenery of Shenhongfa

Sludge Dewatering Filter Presses , XMY800 Round Plate Filter Press , Filter Press Machinenery of Shenhongfa