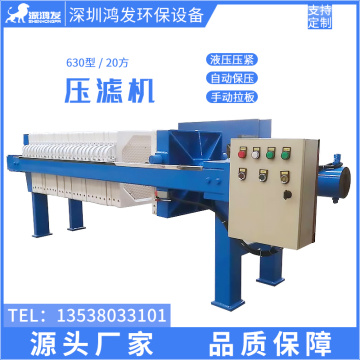

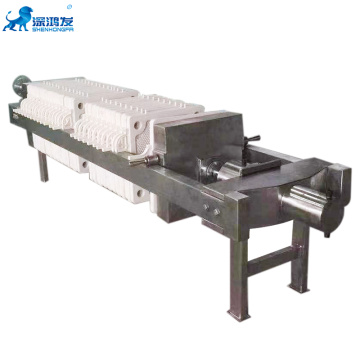

Stainless Steel Multi Layer Plate Frame Filter Press

-

$650.00≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land

- Port:

- Qingdao, Tianjin, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Made in China |

|---|---|

| Productivity: | 500/M |

| Supply Ability: | 500/m |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO9001 ISIO14001 CE,RoHs |

| HS Code: | 84212910 |

| Transportation: | Ocean,Land |

| Port: | Qingdao,Tianjin,Shenzhen |

What's the affect of the stainless steel filter press?

I can provide information that the stainless steel filter press is known for its durability, corrosion resistance, and high-quality filtration. It can effectively filter and separate solids and liquids in various industries such as food and beverage, pharmaceuticals, chemicals, and wastewater treatment. The use of a stainless steel filter press ensures a reliable and efficient filtration process, resulting in high-quality products and reduced operating costs.

1. Prepare the filter press: Ensure that the filter press is clean and free of debris. Install the filter plates and filter cloths according to the manufacturer's instructions.

2. Prepare the slurry: Mix the slurry to be filtered, ensuring that it is well-mixed and has the desired consistency.

3. Fill the filter press: Pour the slurry into the filter press, ensuring that it is evenly distributed across the filter plates.

4. Apply pressure: Use a hydraulic pump or other pressure source to apply pressure to the filter press. The pressure will force the slurry through the filter cloths and filter plates, leaving behind the filtered liquid.

5. Collect the filtered liquid: As the slurry is filtered, the filtered liquid will collect in a collection tray or other container. Monitor the collection container to ensure that it does not overflow.

6. Clean the filter press: Once the filtration is complete, clean the filter press thoroughly to remove any remaining slurry or debris.

Related Keywords