Professional Automatic Stainless Steel Filter Presses

-

$5000.00≥100 Set/Sets

- Min. Order:

- 100 Set/Sets

- Min. Order:

- 100 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Tianjin, Shenzhen, shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,FAS,FCA |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Tianjin,Shenzhen,shanghai |

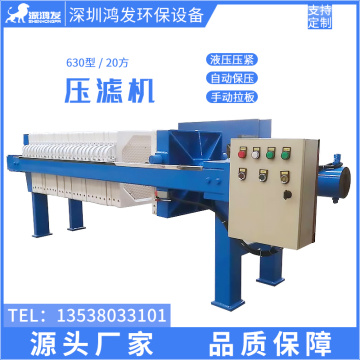

Sludge Dewatering Stainless steel Filter Press

Introduction of Sludge Dewatering Stainless steel Filter Press:

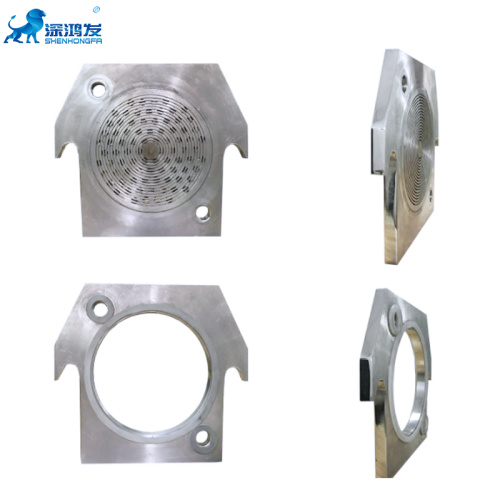

Stainless steel filter press machine is made of 1Cr18Ni9Ti or 304, 306 high quality stainless steel material, corrosion resistance, durable, the filter plate adopts threaded structure, according to different products can be replaced by different filter material (filter material available microporous filter membrane, filter paper, filter cloth, clarification plate, etc.), the sealing ring is made of silicone and fluorine rubber (acid and alkali resistant) two kinds, No leakage, good sealing performance.The suspension is pumped into each closed filter chamber of the filter press. Under the action of working pressure, the filtrate passes through the filter membrane or other filter materials and is discharged through the liquid outlet. The filter residue is left in the frame to form a filter cake, so as to achieve solid-liquid separation.

Main components of filter press:

> Frame: The steel frame acts as a clamping device for the filter plates.

> Filter Plates: A filter cake forms in the chambers between filter plates.

> Filter Cloth: A cloth filter that is attached to both sides of a filter plate. Solids build up on cloth to form a filter cake, separating liquids from solids.

Types of Filter Press according to:

> Closing mode: manual, gear drive, hydraulic;

> Filtrate flow: open flow, close flow, cake washing, non-cake washing, center feeding, corner feeding,etc..

> Filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

> Filter plate material: PP, rubber, cast iron, stainless steel;

> Filter Plate size: 320, 450, 630, 800,1000, 1250, 1500, 2000

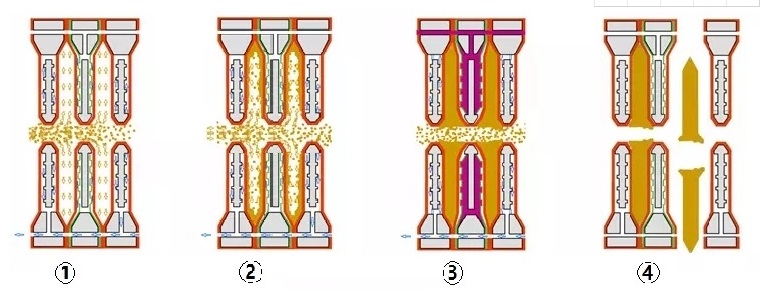

Working principle of Chamber Filter Press:

- 1. Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

- 2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

- 3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

- 4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

WORK SHOP

PRODUCT SHOW

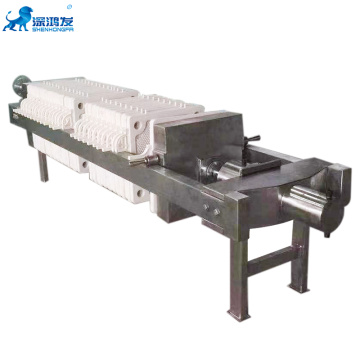

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

Company Profile

Shenzhen HONGFA ENVIRONMENTAL PROTECTION EQUIPMENT CO.,Ltd has become one of the world's leading manufacturers of high-quality filter presses in the field of solid-liquid separation

It is a professional one-stop company covers develop,design,produce,sale and after-service,the company has a professional R&D team, and draws on the advance technology of the world on the products and innovates constantly Company also has environment protection equipment manufacturing factory and filter press accessories manufacturing factory.

The company specializes in filter equipment and related accessories,such as the series of plate and frame filter press,chamber filter press,membrane filter press ,cast iron filter press, stainless steel filter press,filter plate,filter cloth,water faucet and other accessories,filter press be widely used in petroleum,chemical, food ,pharmaceutical,paper making,coal washing , ceramics,mine and other sewage treatment industries

The filter press has 320/450/630/800/1000/1250/1500/2000 type the filtration area ranges from 0.5m2 to 2000m2,Compaction types include jack compaction, mechanical compacting,hydraulic compacting,etc. The material of filter plate contain FRPP,TPE, glass fiber polypropylene,cast iron,stainless steel etc.

Company adhering to the tenet of quality first ,credit important specification complete and id committed to developing to the largest scale and best quality manufacturing company

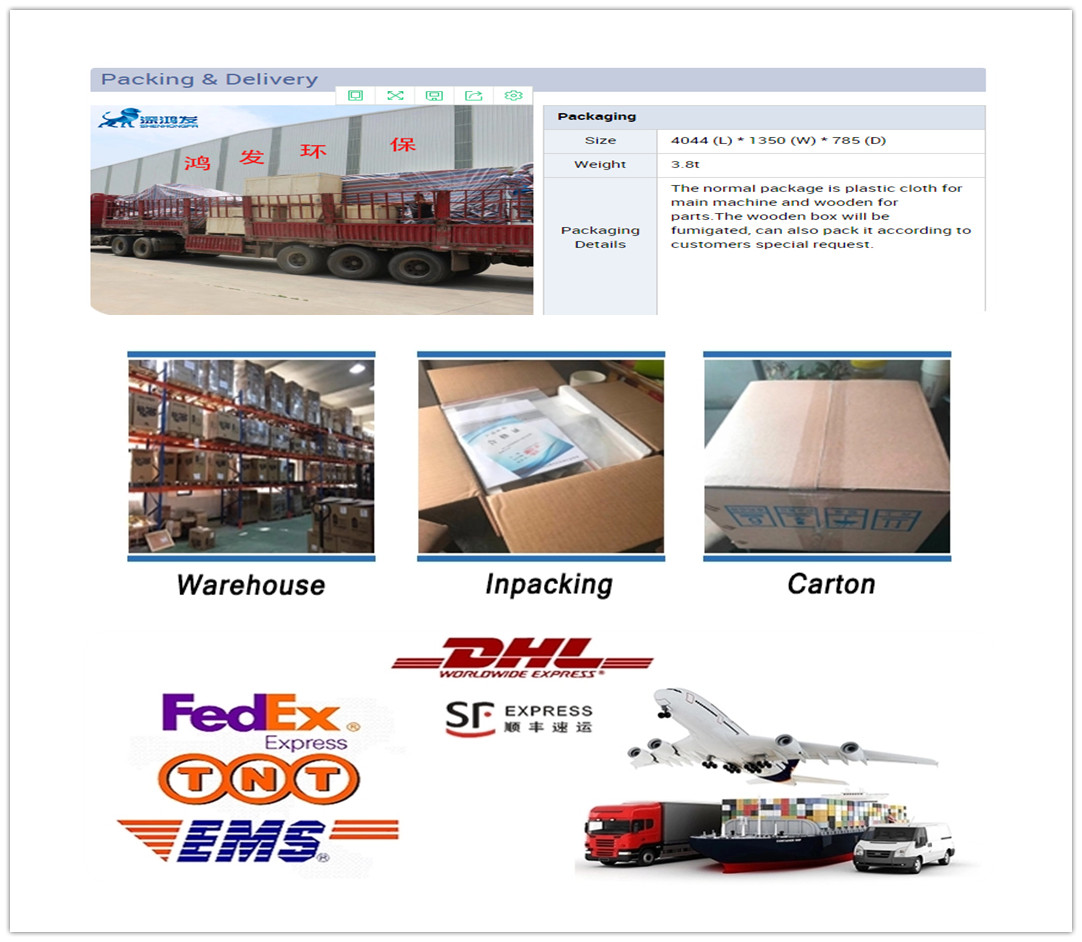

PACKING AND DELIVERY

Our Engineering Project

Advantages of Shenzhen HONGFA Filter Press:

1. Low filter cake moisture;

2. Unmanned operation and cost saving;

3. Resist high temperature and corrosion;

4. Good sealing effect can perfectly avoid leskage;

5. Energy saving high performance chamber filter press with long working life

FAQ:

-------1. How to buy your interested products?

You can provide us the water sources, water quality, flow rate and ground area, material requirements about your project (More details, please contact us).

-------2. How to pay?

L/C or T/T are acceptable.Usually, 50% payment in advance, 50% payment before delivery.

-------3. What is the delivery time?

It depends on order quantities. Generally speaking, the delivery time will be within 1 months.

-------4. How to pack the products?

We use standard export package.If you have special package requirements, we will pack as you required, but the fees will be paid by customers.

-------5. How to install after the equipment arriving destination?

We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

-------6. How long is the validity?

The validity is 12 months after installation

Related Keywords