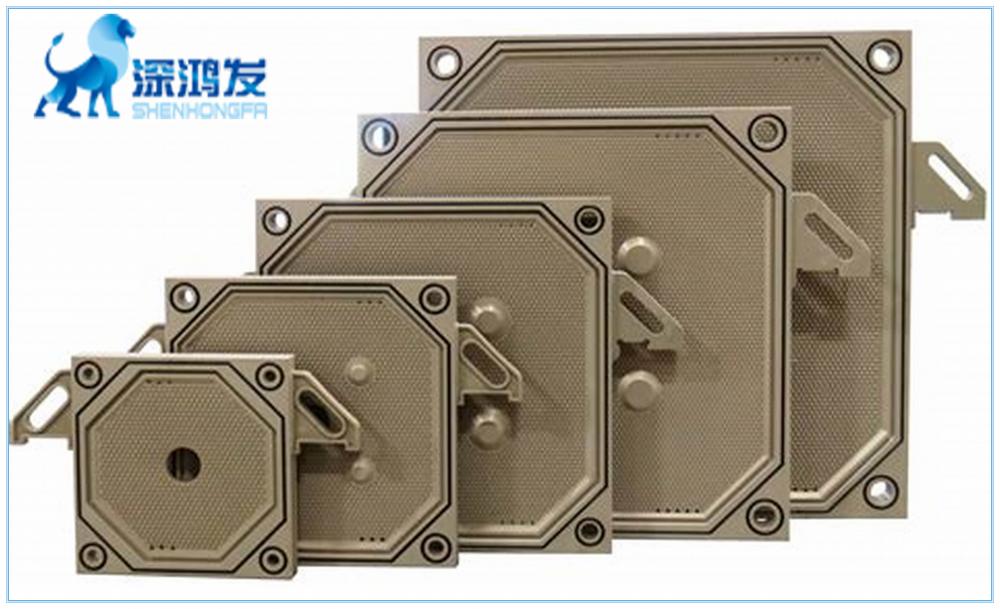

Function: to install filtering medium and ensure filter press can filter normally work at rated pressure.

Material: New reinforced polypropylene material+TPE elastomer type white

Working(filtering/ blowing) pressure: ≤1.0MPa temperature: 80℃

Handles: wear-resisting FRPP, the handle is together with briquette Feeding : central feeding

discharge: close discharge and cake washable