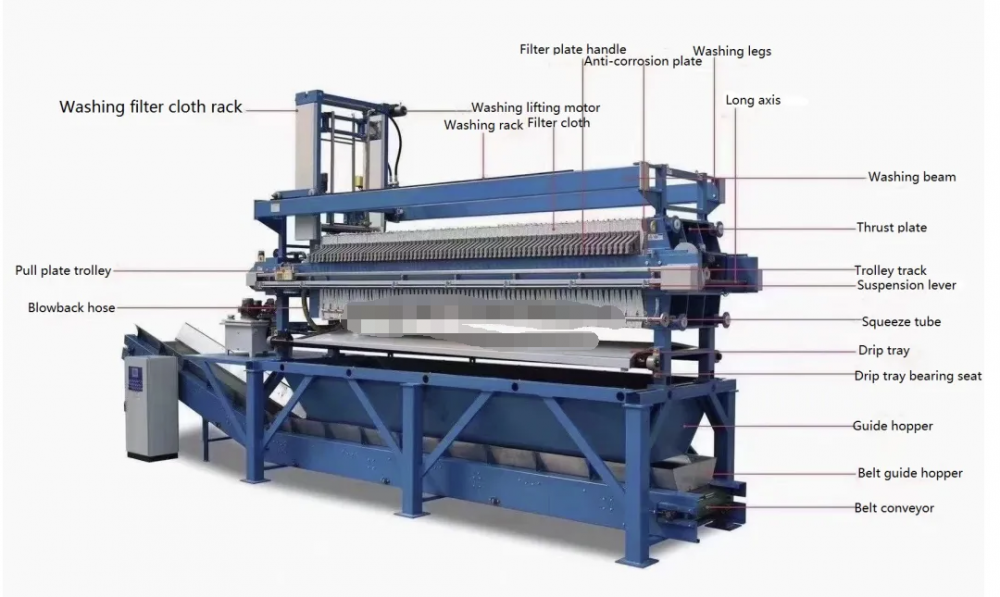

Fullly Automatic High Efficient Filter Press Series

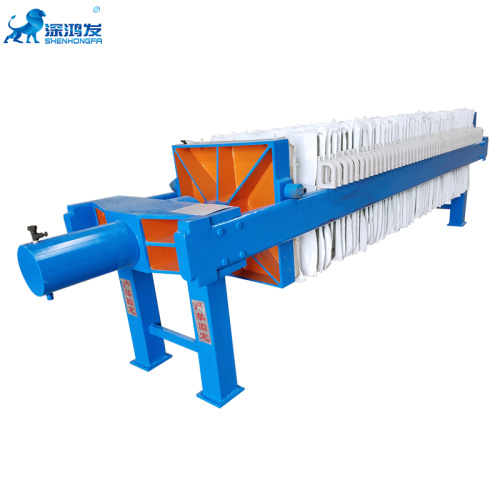

The plate and frame filter press consists of alternately arranged filter plates and filter frames to form a group of filter chambers. The surface of the filter plate is grooved, and the protruding part is used to support the filter cloth. The edge of the filter frame and the filter plate has a hole, which constitutes a complete channel after assembly, and can pass into the suspension, washing water and filtrate. The plate and frame filter press is suitable for suspension with large or nearly incompressible filter slag. The plate frame is usually square, the length of the inner edge of the filter frame is 320 ~ 2000 mm, the thickness of the frame is 16 ~ 80 mm, and the filtration area is 1 ~ 1200 meters 2. The plate and frame are pressed by manual screw, electric screw and hydraulic pressure. Boards and frames are made of materials such as wood, cast iron, cast steel, stainless steel, polypropylene and rubber.

Product Description

Product advantages

This model is an integrated automatic filtration equipment,with a high degree of automation, stable performance,safe and reliable,etc., It is the first choice for customers in such industries as metallurgy, gas, paper making, coking, pharmacy, foodstuff, brewing, fine chemical industry and sewage treatment. It has been widely used in the fields of solid-liquid separation. Compared with the traditional filter press, it added the inclining device system, filter cloth cleaning system and automatic drip tray system, etc., in the industry has great advantages and won a number of domestic patents, is a function Complete filter equipment.

Main Features

1) Simple structure in linear type ,easy in installation and maintain.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

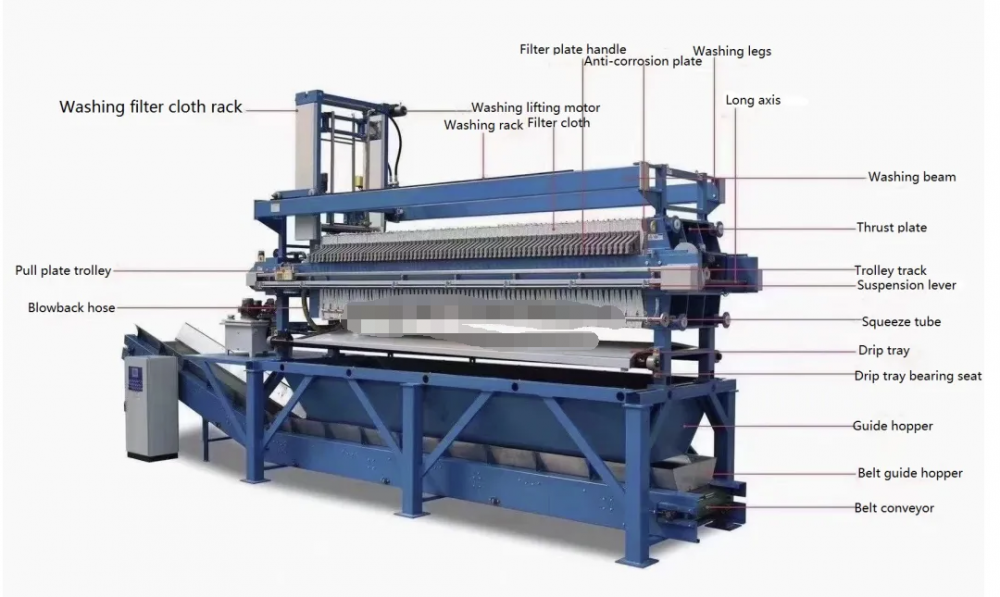

Automatic plate shifting part

|

Automatic plate shifting part

The automatic plate shifting mechanism consists of hydraulic motor, manipulator, transmission mechanism, pause device etc..The hydraulic motor drives the driving chain in order to drive the manipulator to move. Filter plate will be shifted one by one by the plate shifting manipulator. The automatic direction-inverting of the manipulator depends on the time (2-3 seconds) set by time relay (KT1,KT2). The pause device controls the "stop" and "move" actions during the plate shifting process, thus ensure the accomplishment of plate shifting and cake discharge.

|

|

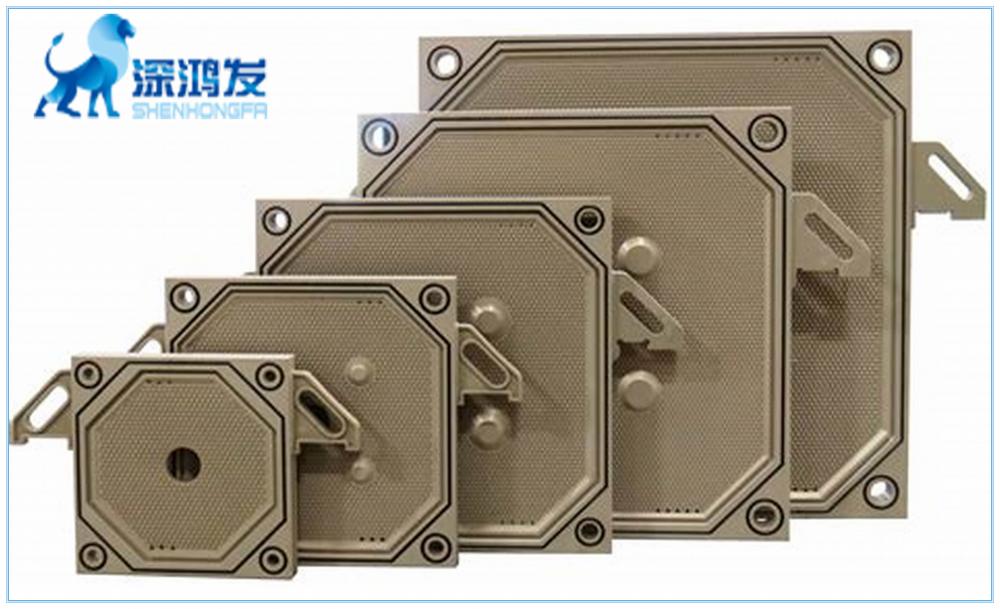

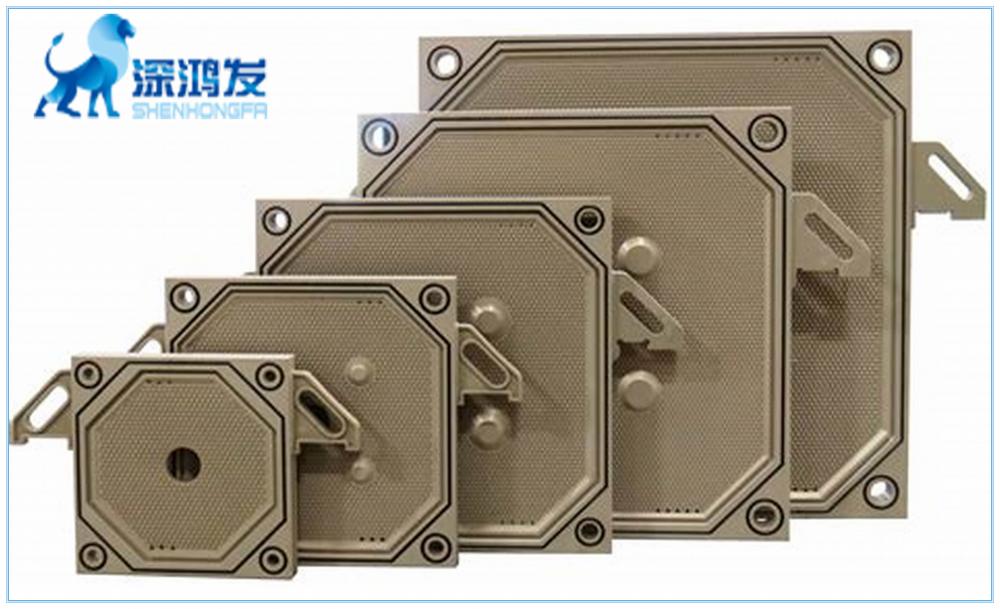

Filter plate

Function: to install filtering medium and ensure filter press can filter normally work at rated pressure.

Material: New reinforced polypropylene material+TPE elastomer type white

Working(filtering/ blowing) pressure: ≤1.0MPa temperature: 80℃

Handles: wear-resisting FRPP, the handle is together with briquette Feeding : central feeding

discharge: close discharge and cake washable

|

|

|

|

Cloth washing system

Filter cloth washing part composite by the cleaning car, cleaning pipe rack and other components. Pull plate cake unloading cake residue on the filter cloth is difficult to fall off, affecting the filter effect, the user should be wash the filter cloth based on the use of the scene.

|

|

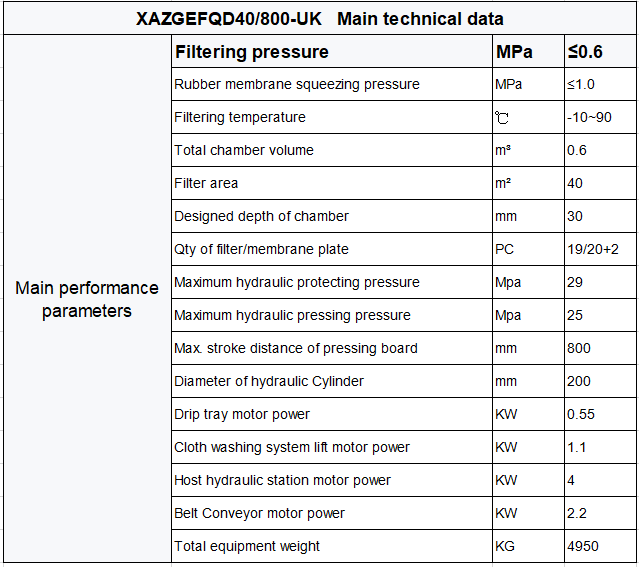

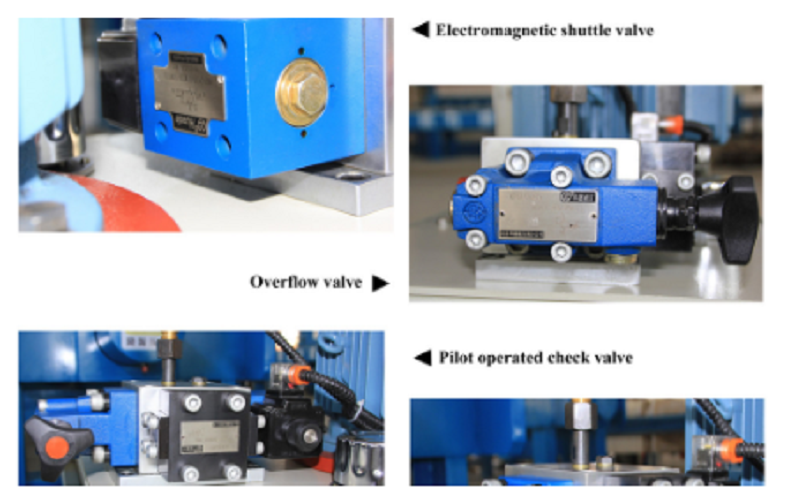

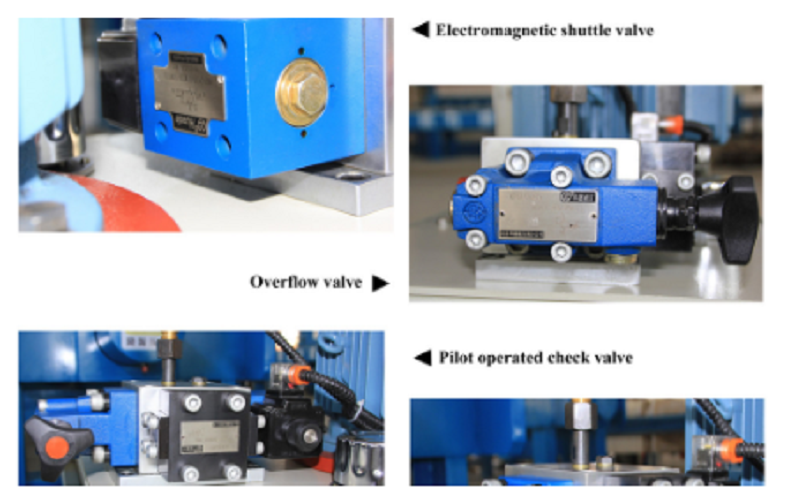

Hydraulic system

Function: to provide pressing power and ensure oil cylinder open/close and manipulator normally work

Makeup: oil tank, oil pump system, manifold block, hydraulic valves, oil pipes, pressure dis-player and driving system.

Max oil pressure,30MPa Rated pressure: 25MPa

|

|