Automatic Waste Water Sludge Dewatering Filter Press

-

$6000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Tianjin,Shanghai |

Automatic Waste Water Sludge Dewatering Filter Press

Introduction of Diaphragm Filter Press:

Advantages of diaphragm filter press:

1. Shorten the filtration time of each batch of materials, improve the utilization rate of the equipment and increase the output.

2. Low pressure feeding and high pressure pressing of diaphragm filter press, so the solid content of filter cake is greatly improved.

3. The pre-pressing technology is used in the process of using the diaphragm filter press, so that the filter cake is formed evenly, conducive to washing, and the water consumption is greatly reduced.

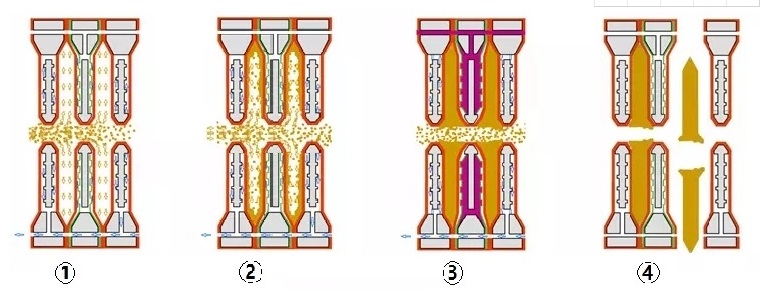

Working principle of Chamber Filter Press:

- 1. Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

- 2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

- 3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

- 4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

Product Description

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

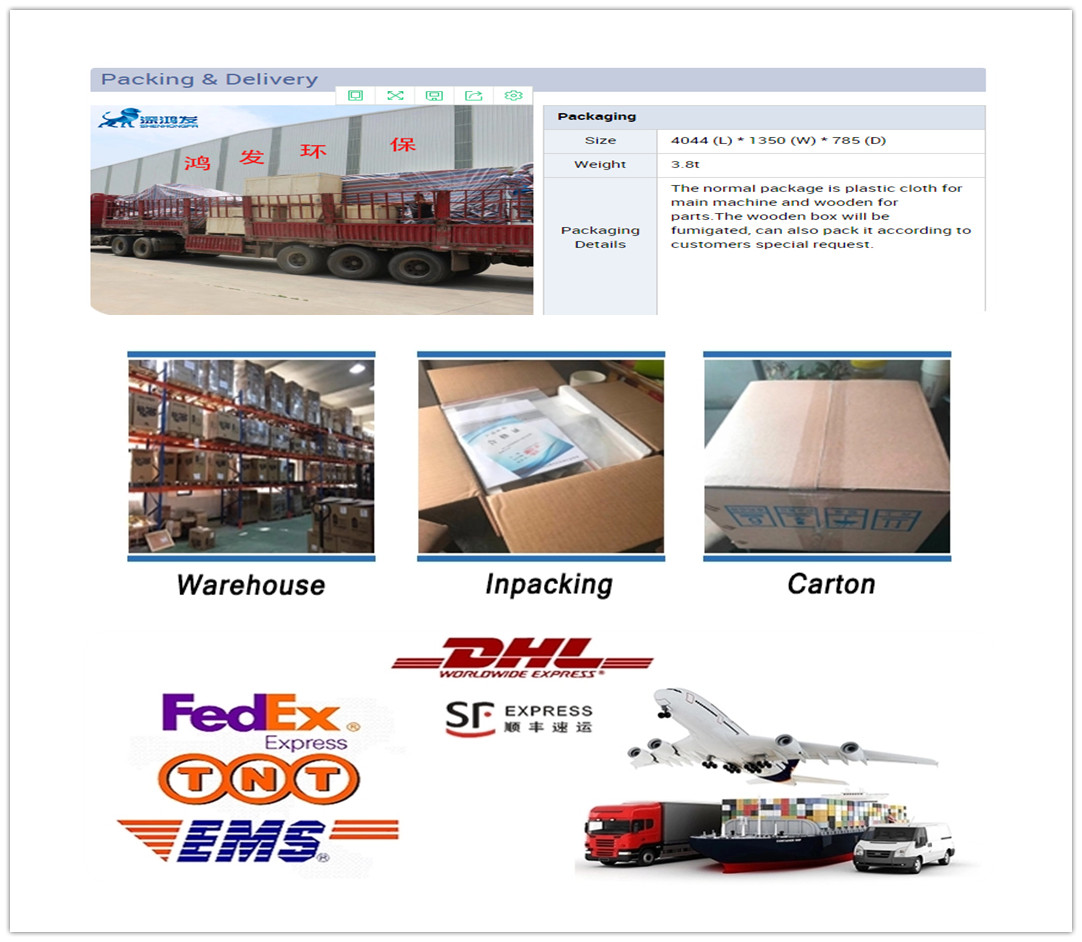

PACKING AND DELIVERY

Our Engineering Project

Advantages of Shenzhen HONGFA Filter Press:

1. Low filter cake moisture;

2. Unmanned operation and cost saving;

3. Resist high temperature and corrosion;

4. Good sealing effect can perfectly avoid leskage;

5. Energy saving high performance chamber filter press with long working life

Related Keywords