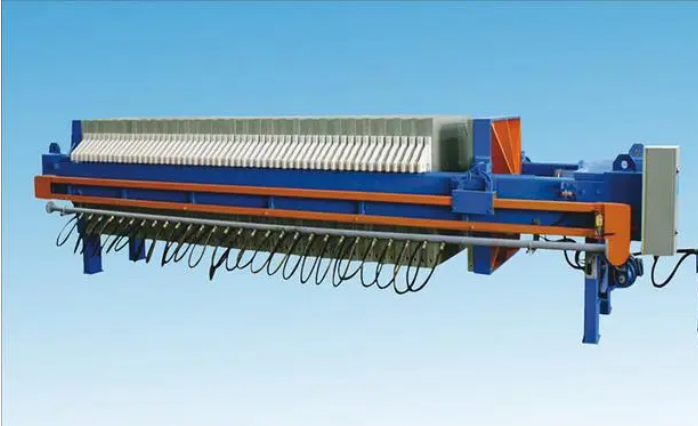

Press Filtration System Machine for Waste Water Treatment

-

$4280.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, TIANJIN, QINGDAO

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 3000sets/month |

| Supply Ability: | 3000sets/year |

| Payment Type: | T/T,Paypal,L/C |

| Incoterm: | FOB,CIF,EXW,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910.90 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,TIANJIN,QINGDAO |

In fact, the diaphragm filter press is similar to the ordinary box or plate and frame filter press. The main structure is the same, and they are all used for the solid-liquid separation of the suspension. However, the compression system of the diaphragm filter press is composed of different parts, which are composed of a frame part, a hydraulic system, a filter part and an electrical control part. The hydraulic system is an important part of the membrane filter press, which regulates the opening of the filter plate and the pressure maintaining of the filter chamber through hydraulic pressure.

advantage:

1. Diaphragm filter press adopts filter plate expansion design. Gas is passed into the filter plate to make it expand and deform, and squeeze the filter cake in the middle of the filter plate, thereby reducing the moisture content of the filter cake.

2. The gas blowback technology is adopted. When the filter press stops feeding, high-pressure gas is introduced into the filter cake of the filter plate to further dry the filtered filter residue, thereby reducing capillary water and structural water in the filter residue. (The combined effect of the previous two advantages can reduce the moisture content of the filter cake of the filter press to about 9%.)

3. The filter plate adopts slope design. The upper part of the feed port of the diaphragm filter press is designed to pass through the sloped filter plate, so that the filtrate can fully contact with the diaphragm to maximize the filtration, improve the filtration speed and increase the work efficiency.

4. The structure of the filter plate. Each filter plate is composed of a combination plate and a polypropylene filter plate, and the combination plate is composed of two filter frames, which is equivalent to filtering with two filter cloths at the same time, which not only facilitates the replacement of filter cloths, but also improves the efficiency. multiplied.

5. The material of the filter plate. The filter plate of the diaphragm filter press is generally made of glass fiber reinforced polypropylene, the membrane is made of natural rubber, and all raw materials are imported.

6. PLC automatic control. The membrane filter press equipment adopts the design of automatic washing filter cloth, which saves water and time. It also adopts automatic unloading design and automatic plate pulling, which can basically be controlled by one person.

Related Keywords