Quick-Opening Membrane/Chamber Filter Press

-

$5000.00≥500 Set/Sets

- Min. Order:

- 500 Set/Sets

- Min. Order:

- 500 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, TIANJIN, SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 3000sets/yeara |

| Supply Ability: | 3000sets/year |

| Payment Type: | T/T,Paypal,L/C |

| Incoterm: | FOB,CFR,FCA,FAS |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84212910.90 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,TIANJIN,SHANGHAI |

Sand washing and slurry dewatering Filter Press

Compared with other types, the filter press with quick opening and automatic washing of press cloth can save labor cost and time and effort.It is not necessary to clean and replace the press cloth frequently, which improves the working efficiency of the press.Now the filter press with automatic cleaning filter cloth is more and more widely used in various industries, for solid-liquid separation needs such as sludge dewatering.

Features of Shenhongfa Filter Press:

1. Short working cycle and high efficiency.

2. Big capacity. Unique plate design makes filtrate discharge more smoothly to make higher processing capacity.

3. Good filtering performance. Our filter press can endure higher feeding pressure, so that get lowest cake moisture.

4. Low running cost. According to CE standard, our filter press has remarkable performance to decrease the running cost.

5. Filter plate are made of reinforced polypropylene with features of high strength, corrosion resistance, nontoxic and odorless.

6. According to your material we will recommend special filter cloth, which can improving the filtering accuracy and efficiency.

7. Main beam material is Q235B/Q345B, with sand blasting processing.

8. Hydraulic station adopt ABB motor ensure stable performance.

9. Hydraulic squeezing ensures no leakage to avoid secondary pollution.

10. Cabinet elements adopts international famous brands: Siemens Schneider etc.

Specifications of Membrane Filter Press Machine:

| Model |

Filter Area (m2) |

Plate Size (mm) |

Cake Thickness (mm) |

Volume (L) |

Plate QTY (PCS) |

Pressure (MPa) |

Dimensions (mm) |

| XMGZ 30/870 | 30 | 870*870 | ≤30 | 427 | 23 |

Feeding: ≤1 MPa, Squeezing: ≤1.5 MPa |

3880*1250*1300 |

| XMGZ 40/870 | 40 | 534 | 29 | 4270*1250*1300 | |||

| XMGZ 50/870 | 50 | 676 | 37 | 4790*1250*1300 | |||

| XMGZ 60/870 | 60 | 818 | 45 | 5310*1250*1300 | |||

| XMGZ 70/870 | 70 | 960 | 53 | 5830*1250*1300 | |||

| XMGZ 80/870 | 80 | 1103 | 61 | 6350*1250*1300 | |||

| XMGZ 50/1000 | 50 | 1000*1000 | 665 | 27 | 4270*1500*1400 | ||

| XMGZ 60/1000 | 60 | 808 | 33 | 4700*1500*1400 | |||

| XMGZ 70/1000 | 70 | 950 | 39 | 5130*1500*1400 | |||

| XMGZ 80/1000 | 80 | 1093 | 45 | 5560*1500*1400 | |||

| XMGZ 100/1000 | 100 | 1378 | 57 | 6410*1500*1400 | |||

| XMGZ 120/1000 | 120 | 1663 | 69 | 7260*1500*1400 | |||

| XMGZ 80/1250 | 80 | 1250*1250 | ≤35 | 1364 | 29 | 4830*1800*1600 | |

| XMGZ 100/1250 | 100 | 1680 | 37 | 5440*1800*1600 | |||

| XMGZ 120/1250 | 120 | 2092 | 45 | 6060*1800*1600 | |||

| XMGZ 140/1250 | 150 | 2547 | 55 | 6820*1800*1600 | |||

| XMGZ 160/1250 | 160 | 2729 | 59 | 7130*1800*1600 | |||

| XMGZ 180/1250 | 200 | 3457 | 73 | 8200*1800*1600 | |||

| XMGZ 200/1250 | 240 | 4093 | 89 | 9420*1800*1600 | |||

| XMGZ 250/1250 | 250 | 4276 | 91 | 9570*1800*1600 | |||

| XMGZ 200/1500 | 200 | 1500*1500 | 3866 | 49 | 7140*2200*1820 | ||

| XMGZ 250/1500 | 250 | 4399 | 61 | 7730*2200*1820 | |||

| XMGZ 300/1500 | 300 | 5199 | 73 | 8720*2200*1820 | |||

| XMGZ 350/1500 | 350 | 6132 | 85 | 10110*2200*1820 | |||

| XMGZ 400/1500 | 400 | 6932 | 99 | 11260*2200*1820 | |||

| XMGZ 450/1500 | 450 | 7731 | 111 | 12250*2200*1820 | |||

| XMGZ 500/1500 | 500 | 8665 | 123 | 13240*2200*1820 | |||

| XMGZ 500/1999 | 500 | 2000*2000 | ≤40 | 9686 | 69 | 10310*2850*2400 | |

| XMGZ 600/2000 | 600 | 11900 | 85 | 11580*2850*2400 | |||

| XMGZ 700/2000 | 700 | 13838 | 99 | 12740*2850*2400 | |||

| XMGZ 800/2000 | 800 | 15775 | 113 | 14100*2850*2400 | |||

| XMGZ 900/2000 | 900 | 17851 | 128 | 15365*2850*2400 | |||

| XMGZ 1000/2000 | 1000 | 19788 | 142 | 16625*2850*2400 |

Why choose Shen HongFa Filter Press

We have professional team in sludge filteration which have many research staffs who have devoted themselves to the industry for more than 20 years, and our High-Efficiency Circular Filter Press for Sludge, saled all over the world.

1),Long history : our factory established in 2014,and we are the leading enterprise in filter press industry .

2),we are one of the main constitutor of press filter regulations.

3),we are a professional team which have many research staffs who have devoted themselves to the industry for more than 20 years.

4),We offer different material's filter plate according to different industry , while other providers couldn't make it .

5), Our products are sold to many companies which most of them are top500 .

6),We manufacture the filter plate ourselves , so we could guarantee its quality ,while other providers buy it from others

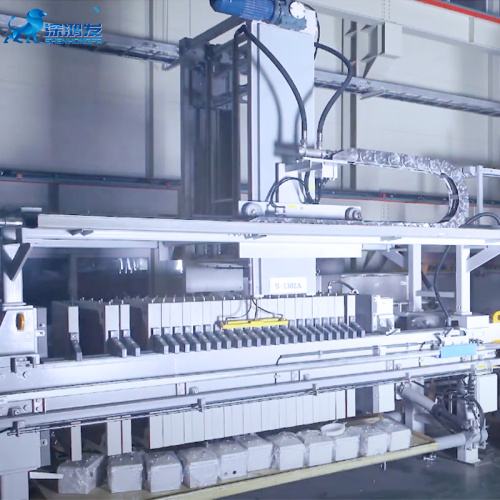

WORK SHOP

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

PACKING AND DELIVERY

Our Engineering Project

Advantages of Shenzhen HONGFA Filter Press:

1. Low filter cake moisture;

2. Unmanned operation and cost saving;

3. Resist high temperature and corrosion;

4. Good sealing effect can perfectly avoid leskage;

5. Energy saving high performance chamber filter press with long working life