Filter Press for printing sludge with CE Certification

-

$20.00≥5 Set/Sets

- Min. Order:

- 5 Set/Sets

- Min. Order:

- 5 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, Tianjin, Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | CHINA |

|---|---|

| Productivity: | 1000set/month |

| Supply Ability: | 1000sets/month |

| Payment Type: | T/T,Paypal,L/C |

| Incoterm: | FOB,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84219990 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,Tianjin,Shanghai |

Product Description

Product Description

A filter press is a valuable piece of equipment for printing sludge because it can effectively separate the liquid and solid components of the sludge. This separation process helps to reduce the volume of waste generated, making disposal more cost-effective and environmentally friendly.

Some of the key benefits of using a filter press for printing sludge include:

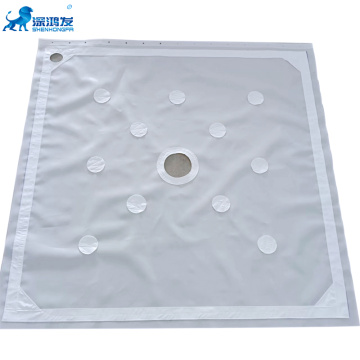

1. Efficient separation: The filter press uses pressure to force the sludge through a series of filter plates, which trap the solid particles while allowing the liquid to pass through. This results in a drier and more concentrated solid waste, reducing the overall volume.

2. Cost savings: By reducing the volume of sludge, a filter press can significantly reduce disposal costs. The drier and more concentrated sludge can also be easier to handle and transport, further reducing expenses.

3. Environmental compliance: Many jurisdictions have strict regulations regarding the disposal of printing sludge. A filter press helps to meet these regulations by effectively separating the solid waste from the liquid, allowing for proper disposal or potential reuse of the liquid component.

4. Increased productivity: A filter press can help improve the efficiency of the printing process by reducing downtime associated with sludge removal and disposal. With a filter press, the sludge can be processed on-site, minimizing interruptions to production.

5. Potential for resource recovery: Depending on the composition of the printing sludge, there may be opportunities for resource recovery. For example, some filter presses are designed to extract valuable materials such as pigments or chemicals from the sludge, which can be reused or sold.

Some of the key benefits of using a filter press for printing sludge include:

1. Efficient separation: The filter press uses pressure to force the sludge through a series of filter plates, which trap the solid particles while allowing the liquid to pass through. This results in a drier and more concentrated solid waste, reducing the overall volume.

2. Cost savings: By reducing the volume of sludge, a filter press can significantly reduce disposal costs. The drier and more concentrated sludge can also be easier to handle and transport, further reducing expenses.

3. Environmental compliance: Many jurisdictions have strict regulations regarding the disposal of printing sludge. A filter press helps to meet these regulations by effectively separating the solid waste from the liquid, allowing for proper disposal or potential reuse of the liquid component.

4. Increased productivity: A filter press can help improve the efficiency of the printing process by reducing downtime associated with sludge removal and disposal. With a filter press, the sludge can be processed on-site, minimizing interruptions to production.

5. Potential for resource recovery: Depending on the composition of the printing sludge, there may be opportunities for resource recovery. For example, some filter presses are designed to extract valuable materials such as pigments or chemicals from the sludge, which can be reused or sold.

Overall, the value of a filter press for printing sludge lies in its ability to efficiently separate the liquid and solid components, reducing waste volume and associated costs, ensuring compliance with regulations, and potentially enabling resource recovery.

Related Keywords

Related Keywords

You May Also Like

You May Also Like