Large Processing Capacity Belt Filter Press

-

$2000.00≥1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Tianjin, Shenzhen, Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 3000sets/year |

| Supply Ability: | 3000sets/year |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | CFR,FOB,FAS,FCA |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Tianjin,Shenzhen,Shanghai |

Product Description

Product Description

Sludge Dewatering Filter Press

The advantages of belt filter press:

1. The belt type filter has low electrical consumption and large processing capacity.

2, belt filter press dewatering efficiency is high, mud cake solid content is high.

3. The operation and management of belt filter press are simple and easy to maintain.

4, belt filter press high degree of automation, continuous production.

5, belt filter press low noise, long service life.

6. Belt filter press has less auxiliary equipment, economic and reliable, and wide application range.

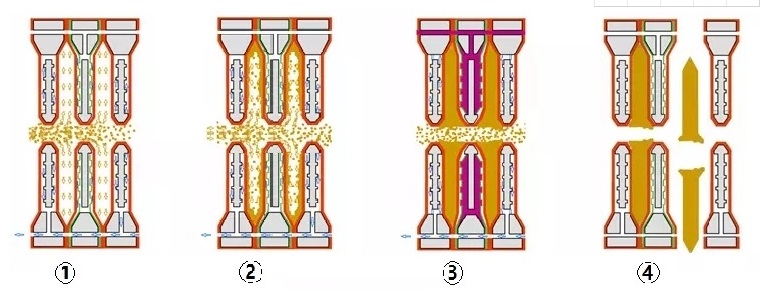

Working principle of Chamber Filter Press:

- 1. Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

- 2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

- 3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

- 4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

Why choose Shen HongFa Filter Press

We have professional team in sludge filteration which have many research staffs who have devoted themselves to the industry for more than 20 years, and our High-Efficiency Circular Filter Press for Sludge, saled all over the world.

1),Long history : our factory established in 2014,and we are the leading enterprise in filter press industry .

2),we are one of the main constitutor of press filter regulations.

3),we are a professional team which have many research staffs who have devoted themselves to the industry for more than 20 years.

4),We offer different material's filter plate according to different industry , while other providers couldn't make it .

5), Our products are sold to many companies which most of them are top500 .

6),We manufacture the filter plate ourselves , so we could guarantee its quality ,while other providers buy it from others

WORK SHOP

PRODUCT SHOW

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

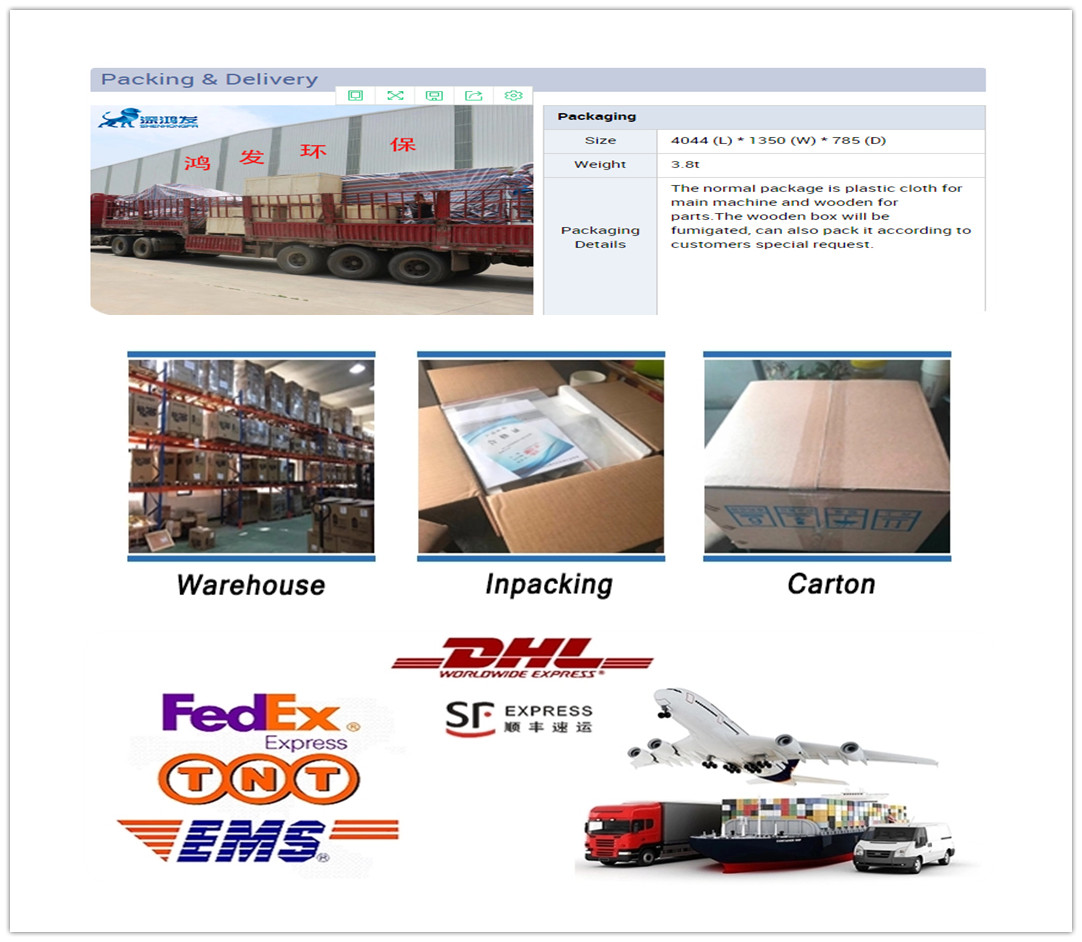

PACKING AND DELIVERY

Our Engineering Project

Related Keywords

Related Keywords

You May Also Like

You May Also Like