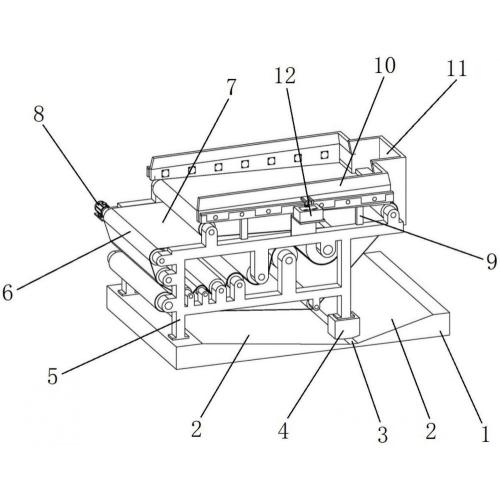

Metallurgical Sludge Tailing Sludge Filter Press

-

$5000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS |

| Certificate: | CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Qingdao,Shanghai |

Shenzhen Hongfa belt filter press manufacturer

In addition to the continuous production, simple operation and less auxiliary equipment of other domestic models of belt filter presses, the belt sludge filter press has the notable advantages of large processing capacity, dehydration, easier operation, and lower investment and energy consumption. It is a new type of solid-liquid separation equipment with low cost and low cost, applicable to all kinds of sludge, and easy to form a network control with other sewage treatment equipment.Belt filter press is widely used in sludge dehydration in urban domestic sewage, textile printing and dyeing, electroplating, papermaking, leather, brewing, food processing, coal washing, petrochemical, chemical, metallurgy, manufacturing, ceramics and other industries. It is also suitable for industrial Production of solid separation or leaching process.

Wide application: 1. It is suitable for sludge in municipal sewage, food, beverage, chemical industry, leather, welding consumables, papermaking, printing and dyeing, manufacturing and other industries. 2. Suitable for dehydration of high and low concentration sludge. When dewatering low-concentration (2000mg/L~) sludge, there is no need to build thickening tanks, storage tanks, construction costs, phosphorus release and anaerobic odor generation.

Not easy to block: 1. It has the function of self-cleaning. There is no need for cleaning to prevent clogging of filter seams, flushing water consumption, and internal circulation burden. 2. Good at dehydration of oily sludge.

Low-speed operation: 1. The rotation speed of the screw shaft is about 2~3 rpm, and the power consumption is low. 2. Few faults, low noise and vibration, safe operation.

Simple operation: 1. Through the electric control cabinet, it is linked with the foaming machine, mud feeding pump, filling pump, etc. to realize 24-hour continuous unmanned operation. 2. The daily time is short and the work is simple.

Durable: 1. The body is almost entirely made of stainless steel, which can maximize the service life. 2. The replacement parts are only the screw shaft and the ring, and the service life is long.

Related Keywords