Ore Dressing Tailings Dewatering Filter Press

-

$6000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 200sets/month |

| Supply Ability: | 200sets/month |

| Payment Type: | T/T,L/C,Paypal |

| Incoterm: | FOB,CIF,EXW,FAS |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Qingdao,Shanghai |

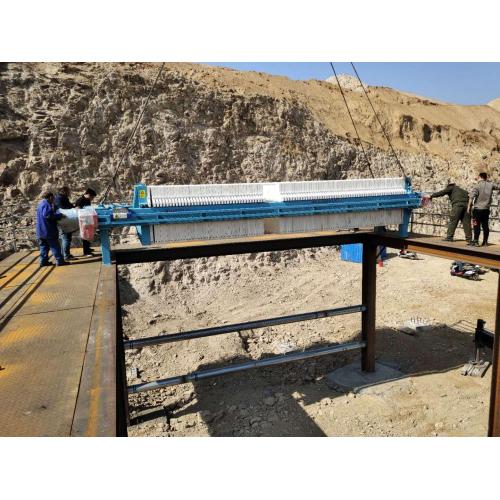

Filter Press for Tailings

Tailings filter press after the end of the filtration work, there is a work must not forget, that is to clean the filter press. Poor cleaning will not only make the machine work less efficiently, but may also damage the equipment.During the operation of the tailings filter press, the solids in the filtrate will be intercepted on the filter plate to form the filter cake, and the closely arranged filter plates will be disassembled by manual unloading plate or automatic unloading plate, so that the filter cake in the middle will fall down. However, there will be some residual stains left on the filter plate, which will damage the tightness. When filtering again, the filtrate may be blocked through the filter plate orifice and cause the deformation of the filter plate. So after the cake is removed, the filter plate should also be rinsed.

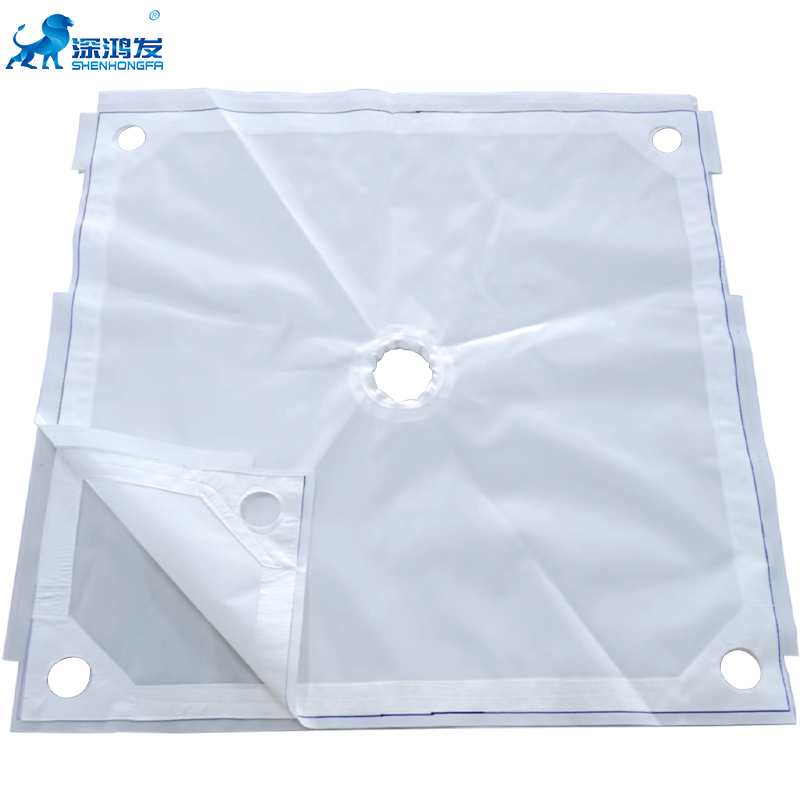

The filter cloth is wrapped on the filter plate. Different filter cloth can be selected according to the different materials to be filtered. After each filtration task, the filter cloth needs to be cleaned. The filter cloth is first removed from the plate, soaked for a period of time, and then cleaned with a soft brush. It can also be soaked for about 10 hours in a solution opposite to the acid and alkaline of the filter cloth according to the different acid and alkaline of the filter cloth itself, and then rubbed clean, rinsed clean with clean water and dried.

The cleaning of the filter plate and cloth of the tailings filter press may be a very headache for some users, which is not only a waste of time, but also requires manual operation. The appearance of automatic cleaning tailing filter press solves this problem. The cleaning device is installed below the filter plate. After the tailings filter press completes the filtering task and removes the filter cake, the high pressure water is sprayed automatically to realize the cleaning work of the filter cloth filter plate.

Tailings filter press to use longer time, filter press use efficiency is higher, cleaning work must be done in accordance with the requirements.

Related Keywords