Sludge Dewatering for Wastwater Treatment filter press

-

$4500.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Tianjin, Shenzhen, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 2500sets/year |

| Supply Ability: | 2500sets/year |

| Payment Type: | T/T,Paypal,L/C |

| Incoterm: | FOB,CIF,EXW,FAS,FCA,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 84231916.90 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Tianjin,Shenzhen,Qingdao |

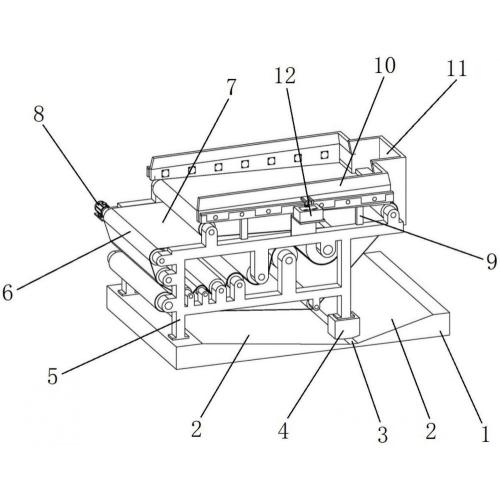

What does a belt filter press do?

In order to ensure the normal operation of the filter press, some relevant cooperation must be done on site. For example, if some sewage does not meet the optimal working conditions of the filter press, it cannot enter the filter press for sludge dewatering. The dehydration process of the belt filter press can be divided into four important stages: pretreatment, gravity dewatering, wedge-shaped zone pre-pressing dehydration and press dehydration. It is an environmentally friendly filter product for integrated sewage sludge treatment.

After the original sewage is processed, it is precipitated and concentrated. A part of the clean water is discharged, while the rest forms sludge with a higher consistency to achieve the best working conditions of the belt filter press. After that, it goes through the gravity dehydration zone, wedge-shaped zone pre-dehydration section, and then to the high-pressure dehydration section to minimize the water content of the filter cake. Finally, the filter cake is scraped off by the mud scraper, the upper and lower filter belts are separated, and the filter cake is cleaned by high-pressure flushing water. The trace materials between the meshes continue to be further dehydrated.

Related Keywords