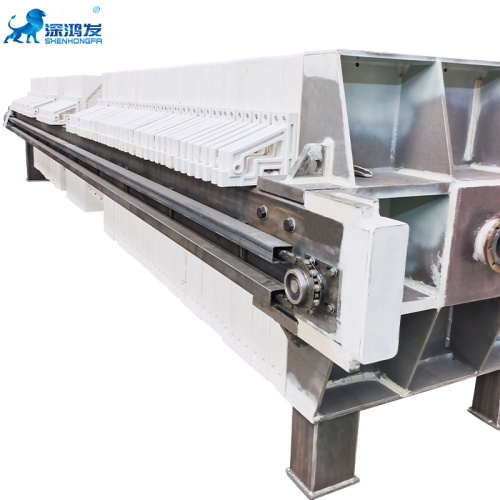

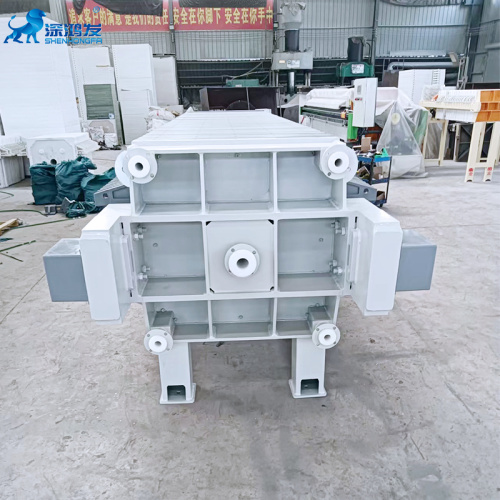

Automatic Filter Press for Industrial Wastewater Treatment

-

$2000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Express, Air

- Port:

- shenzhen, qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 5000sets/year |

| Supply Ability: | 5000sets/year |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CIF,EXW,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Express,Air |

| Port: | shenzhen,qingdao |

Filter press is generally composed of head plate, tail plate, filter plate, hydraulic cylinder, main beam, transmission and pulling device. The hydraulic cylinder piston pushes the head plate, so that the filter plate presses the adjacent filter plate to form the filter chamber; The mud is sent to the filter chamber by the mud pump. The water permeates the filter cloth and is discharged through the drain port. The solid mud forms the filter cake in the filter chamber. When the mud fills the filter chamber, a high pressure pump continues to pressure filter the mud, so that the solid and liquid in the filter chamber separation. 1. Press the filter plate: Operate the hydraulic system to make the tail plate move in the direction of the head plate, and press the whole filter plate between the head plate and the tail plate. Therefore, a hollow sealed filter chamber is formed between the adjacent filter plates. 2. Pressure filtration process: the feed pump will be mud from the feed hole of the tail plate to the filter chamber, when the filter chamber is full of mud, the pressure filtration process begins, mud with the pressure of the feed pump, solid-liquid separation. 3. Release the filter plate: operate the hydraulic system and return the head plate to the original position. 4. The transmission chain on the filter plate discharging transmission and pulling device will pull the filter plate apart one after another, and the filter cake will fall off by virtue of its own weight and be transported away by the lower conveyor. At the early stage of filter press, the thickness of mud cake in the filter chamber is not big, the resistance of cake is small, and the dehydration speed is fast. Usually, low head and large flow pump are used at this time. With the increase of cake thickness and resistance, the pressure filter speed decreases. At this time, high head and low flow pump are used. The time required by the filtration process is determined according to the filtration characteristics and technological requirements of the mud. When the specified filtration time is reached, the feeding is stopped and the filtration process is completed. The water-bearing sludge filter press is transported to the sludge mixing tank by the sludge pump, at the same time, the coagulant is added for full mixing reaction, and then flows into the belt sludge press and mud distributor. The sludge is evenly distributed to the gravity dewatering area, and under the two-way dredging of the mud rake and the action of gravity, the sludge quickly removes the free water of the sludge along with the movement of the dewatering filter belt. As the gravity dehydration zone is designed to be long, the maximum gravity dehydration can be achieved. The sludge turned down enters the long wedge-shaped precompression dewatering area and slowly traps the sludge unloaded in the gravity area to form a sandwich-like Angle layer. The sequential slow precompression filtration is carried out to reduce the residual free water in the mud layer. As the upper and lower two filter belts slowly advance, the upper and lower distance between the two filter belts gradually decreases, and the mud layer in the middle gradually stiffens. A large amount of free water is removed by prepressing and dewatering the filter roller with a large diameter, so that the mud cake smoothly enters the extrusion dewatering area and enters the press section. In the press section, the sludge is sandwiched between the upper and lower two layers of press cloth and is repeatedly pressed by several press rollers. When the upper and lower two filter belts pass through the wavy path formed by staggered rollers, the upper and lower positions of the two filter belts alternate in order to generate shear force on the clamped mud cake, which will accumulate and filter most of the remaining water in the sludge and promote the mud cake to dehydrate again. After that, the dry mud cake is scraped off with a scraper and transported to the sludge storage place by a belt conveyor or shafless screw conveyor.Automatic plate pulling chamber filter press

Related Keywords