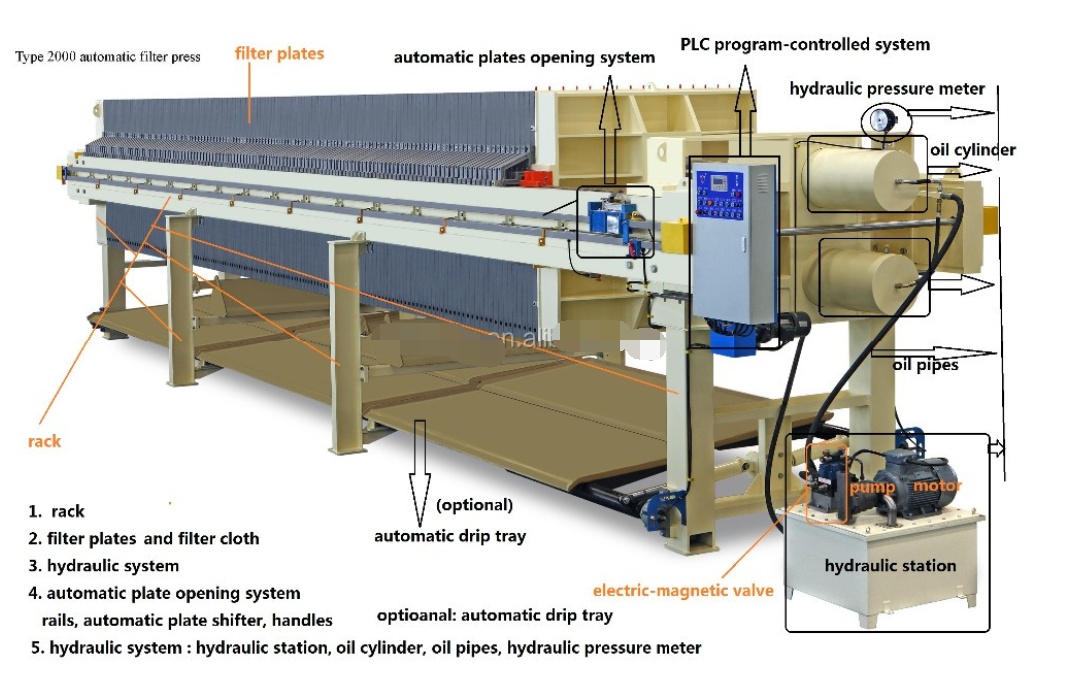

Round high pressure filter press

-

$6000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- shenzhen, qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 5000sets/year |

| Supply Ability: | 5000sets/year |

| Payment Type: | T/T,L/C,Paypal |

| Incoterm: | FOB,EXW,DDP,DDU,Express Delivery |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air |

| Port: | shenzhen,qingdao |

Sludge dewatering filter press washing method

When the filter cake needs washing, sometimes one-way washing and two-way flow washing, one-way washing and two-way subsurface washing. The surface of the filter plate is provided with a pit and a boss supporting the filter cloth. There are through holes in the middle and corners of the filter plate, which form a complete channel after assembly to allow suspension, washing water and filtrate to enter. The beam on both sides of the filter plate is respectively provided with a handle support, and the filter plate is pressed by a pressing device. The press cloth between the filter plates acts as a seal. Under the pressure of the feed pump, the material liquid to be filtered is sent to the filtration chamber, and the solid and liquid are separated by the filtration medium (suitable filter cloth is selected according to the requirements of no counterparts). Filter slag is formed on the filter cloth until the filter chamber is filled to form filter cake. Filtrate through the filter cloth, along the groove of the filter plate flow down the liquid channel concentrated discharge. After filtration, clean washing water can be introduced to wash the filter residue. After washing, compressed air is sometimes introduced to remove the remaining washing liquid. After filtration, turn on the filter press, remove the filter cake (which is stored between two adjacent filter plates), clean the filter cloth, press the plate filter again, and begin the next working cycle. The press cloth is fixed to the plate frame, which was the main form of early filter press. The main advantages of the van type sludge filter press are convenient to replace the press cloth, but the disadvantages are low efficiency, poor filtration effect and easy to damage the filter plate. The filter chamber of the van type sludge filter press is composed of two adjacent sinking filter plates, and the filter cloth is fixed on each filter plate. The sludge can be dehydrated by river sludge filter press, and the sludge cake with low moisture content can be formed to realize the reduction of sludge. Automatic plate pulling chamber filter press,The river dredging sludge filter press produced by Su Dong is a kind of energy-saving filter press that can work continuously without energy consumption of high-power motor and can complete the continuous production of mud cake by simple chemical reaction and physical mechanical filter press. At the same time, it can also meet the requirements of filter cake moisture content. The moisture content of mud cake can be reduced to about 20% after mud filtration and dehydration. Mud water into mud lumps, greatly reduce the volume of transportation, but also easy to transport, reduce the adverse impact on the transportation line environment. Under the premise of economy, safety and environmental protection, the centralized disposal and resource utilization of river silt are realized, and the "reduction, harmless, stabilization and resource utilization" of sludge is realized.

Related Keywords