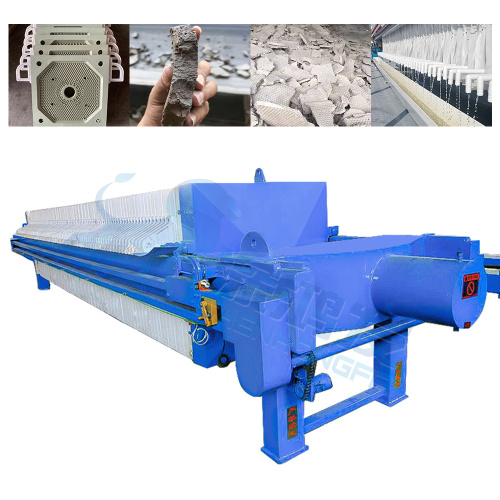

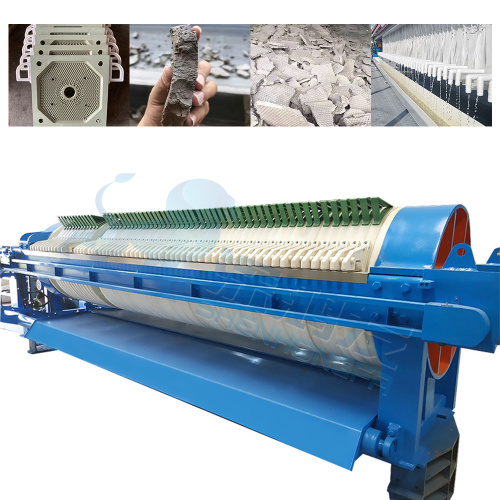

Automatic Chamber Filter Press System

-

$6800.001-2 Set/Sets

-

$6000.00≥3 Set/Sets

- Transportation:

- Land, Ocean, Air, Express

- Port:

- shenzhen, qingdao, shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 5000sets/year |

| Supply Ability: | 5000sets/year |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Land,Ocean,Air,Express |

| Port: | shenzhen,qingdao,shanghai |

When the box filter press works, the hydraulic cylinder is used to press all the filter plates between the movable head plate and the fixed tail plate, so that the adjacent filter plates form a sealed filter chamber, and the pulp is fed to a certain pressure from the feeding hole of the fixed tail plate. After all the filtration chambers are filled with slurry, the filtration process begins, and the slurry is separated by the pressure of the feed pump into the slurry. The solid particles remain in the filter chamber due to the blocking of the filter cloth, and the filtrate is discharged through the filter cloth along the drain on the filter plate. After a period of time, the filtrate no longer flows out, that is, the dehydration process is completed. At this point, can stop feeding, through the hydraulic control system adjustment, the head plate back to the original position; The filter plate is pulled apart by the filter plate moving device; The cake falls off by its own weight and is carried away by a belt on the lower part. In order to prevent hole blockage of press cloth and affect filtration effect, the press cloth should be cleaned after cake unloading. At this point, the whole filtration process has been completed.

Related Keywords