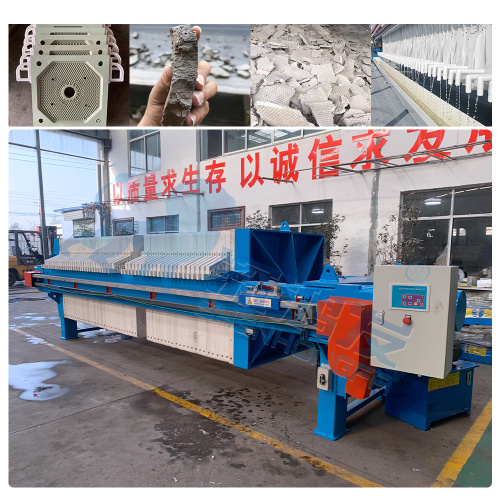

Filter press for sewage treatment

-

$1500.001-2 Set/Sets

-

$1100.00≥3 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5000sets/year |

| Supply Ability: | 5000sets/year |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Certificate: | ISO CE ROHS |

| HS Code: | 84212910 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Qingdao,Shanghai |

Application of ultra-high pressure filter press in slime industry

Slime is a by-product of raw coal washing and processing in coal preparation plant. For steam coal preparation plant coal slime generally refers to primary coal slime, coking coal preparation plant coal slime generally refers to floatation tailings coal slime. Some coal preparation plants with coarse particle size of coal slime can use pressure filter to recover, a few coal preparation plants use belt filter press to recover coal slime, the vast majority of coal preparation plants use plate and frame filter press for coal slime recovery and key check equipment. The moisture of coal slime cake recovered by plate and frame filter press in coal preparation plants is usually between 25% and 40%, and the calorific value of most slime is between 10.49 and 14.64 MJ/kg. These slime due to high moisture, low caloric value, appearance of sticky wet "clumps", directly mixed into the product coal most users do not accept, can only be ground storage. Coal preparation plants located in coal shortage areas can still be sold at low prices on the spot, coal preparation plants located in coal concentrated areas a large part of the slime is abandoned. It not only wastes resources, but also causes serious environmental pollution due to the transportation and spontaneous combustion of slime. The outlet problem of slime even becomes an important factor restricting the production of coal preparation plant. In recent years, in order to solve the problem of slime landing, many coal preparation plants have adopted new diaphragm filter press and through-flow filter press, etc., trying to reduce the slime moisture through secondary press, air flow and other technologies. On the whole, except some coal preparation plants achieve better results, most of the coal slime moisture reduction range is limited. Some coal preparation plants adopt coal slime thermal drying process to dewatering coal slime, which has achieved good results and economic benefits. Coal slime drying has almost become the ultimate means to solve the problem of coal slime landing. At present, the most commonly used slime drying equipment is drum dryer and rotor dryer, generally can reduce the moisture of slime 10% ~ 15%, improve the heat of slime 2.09 ~ 3.35 MJ/kg, dried slime products appear very loose "granular", can be mixed into the product coal or local sales, Increased the added value of slime.High pressure membrane filter press.

In order to solve the big problem of high moisture and stickiness of coal slime recovery products, recently domestic equipment manufacturers have developed a new path, drawing on some technical experience of sludge recovery industry, and developed ultra-high pressure plate frame filter press specially suitable for coal slime recovery in coal preparation plant. The type of filter press adopts the feeding pressure and pressing pressure of the plate and frame press and the diaphragm filter press, which greatly reduces the moisture of the slime products. With the slime crusher, the slime products are broken into "dry powder", which is fully equipped with the conditions for the sale of coal products. The application effect of this technology in East China, northern Shaanxi, Binchang and other regions shows that the slime moisture of ultra-high pressure filter press can be compared with the ordinary plate frame type and diaphragm type filter press, the slime moisture can be reduced by 5% ~ 10% on average, and the calorific value can be increased by 1.26 ~ 2.09 MJ/kg, so as to realize "no slime" production in coal preparation plant. While solving the slime outlet problem of coal preparation plant, considerable economic benefits have been obtained.

In order to solve the big problem of high moisture and stickiness of coal slime recovery products, recently domestic equipment manufacturers have developed a new path, drawing on some technical experience of sludge recovery industry, and developed ultra-high pressure plate frame filter press specially suitable for coal slime recovery in coal preparation plant. The type of filter press adopts the feeding pressure and pressing pressure of the plate and frame press and the diaphragm filter press, which greatly reduces the moisture of the slime products. With the slime crusher, the slime products are broken into "dry powder", which is fully equipped with the conditions for the sale of coal products. The application effect of this technology in East China, northern Shaanxi, Binchang and other regions shows that the slime moisture of ultra-high pressure filter press can be compared with the ordinary plate frame type and diaphragm type filter press, the slime moisture can be reduced by 5% ~ 10% on average, and the calorific value can be increased by 1.26 ~ 2.09 MJ/kg, so as to realize "no slime" production in coal preparation plant. While solving the slime outlet problem of coal preparation plant, considerable economic benefits have been obtained.

Related Keywords