Hydraulic Automatic Pressure Retaining Filter Press

-

$2000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- shenzhen, tianjin, shanghai

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100sets/month |

|---|---|

| Transportation: | Ocean,Land |

| Port: | shenzhen,tianjin,shanghai |

-

Hydraulic Automatic Pressure Retaining Filter Press for Mud Treatment

Introduction of Filter Press:

Hydraulic automatic pressure retaining filter press adopts hydraulic device as the power mechanism of pressing and loosening the filter plate,and the electric contact pressure gauge is used to realize automatic pressure preservation.With simple and safe operation, labor-saving, the whole machine works stably;With the electrical part equipped with a variety of safety devices, the safety of the operator and the normal use of the filter press can be guaranteed.

Main components of filter press:

> Frame: The steel frame acts as a clamping device for the filter plates.

> Filter Plates: A filter cake forms in the chambers between filter plates.

> Filter Cloth: A cloth filter that is attached to both sides of a filter plate. Solids build up on cloth to form a filter cake, separating liquids from solids.

Types of Filter Press according to:

> Closing mode: manual, gear drive, hydraulic;

> Filtrate flow: open flow, close flow, cake washing, non-cake washing, center feeding, corner feeding,etc..

> Filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

> Filter plate material: PP, rubber, cast iron, stainless steel;

> Filter Plate size: 320, 450, 630, 800,1000, 1250, 1500, 2000

Product Description

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

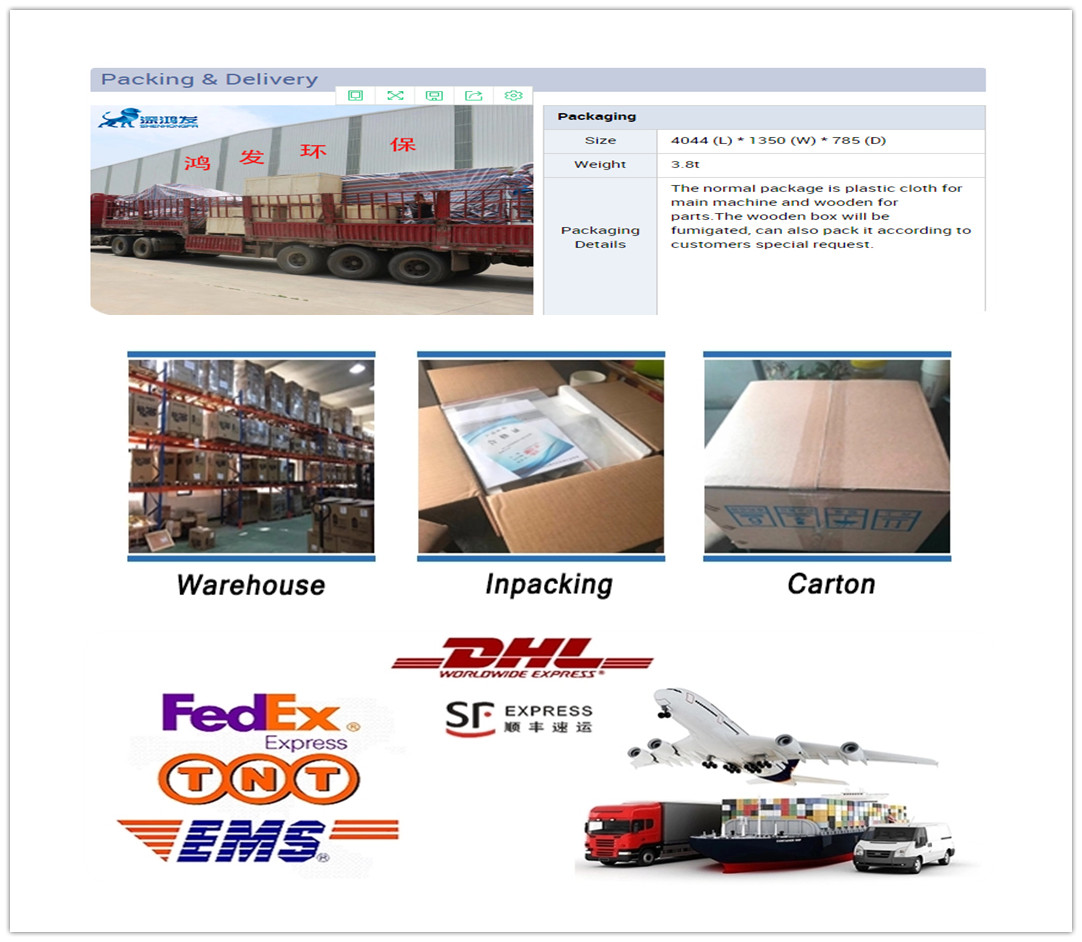

PACKING AND DELIVERY

Related Keywords