Full Automatic High Efficiency Filter Press selection

-

$5000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Land, Air, Express, Ocean

- Port:

- Shenzhen, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000sets/year |

| Supply Ability: | 3000sets/year |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| Transportation: | Land,Air,Express,Ocean |

| Port: | Shenzhen,Tianjin,Shanghai |

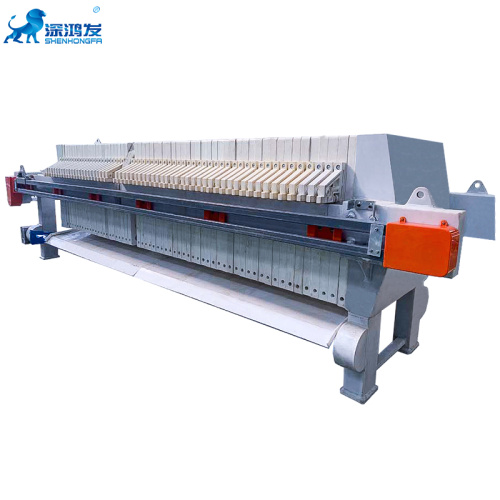

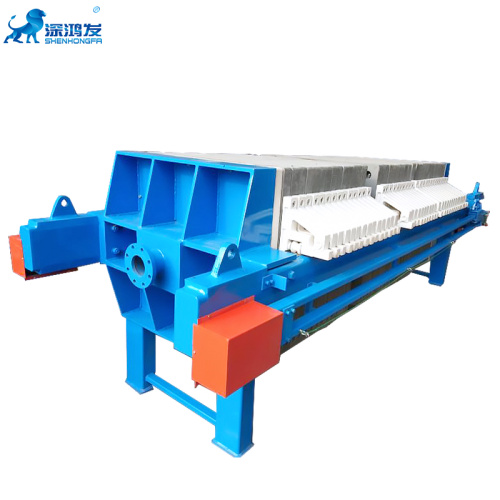

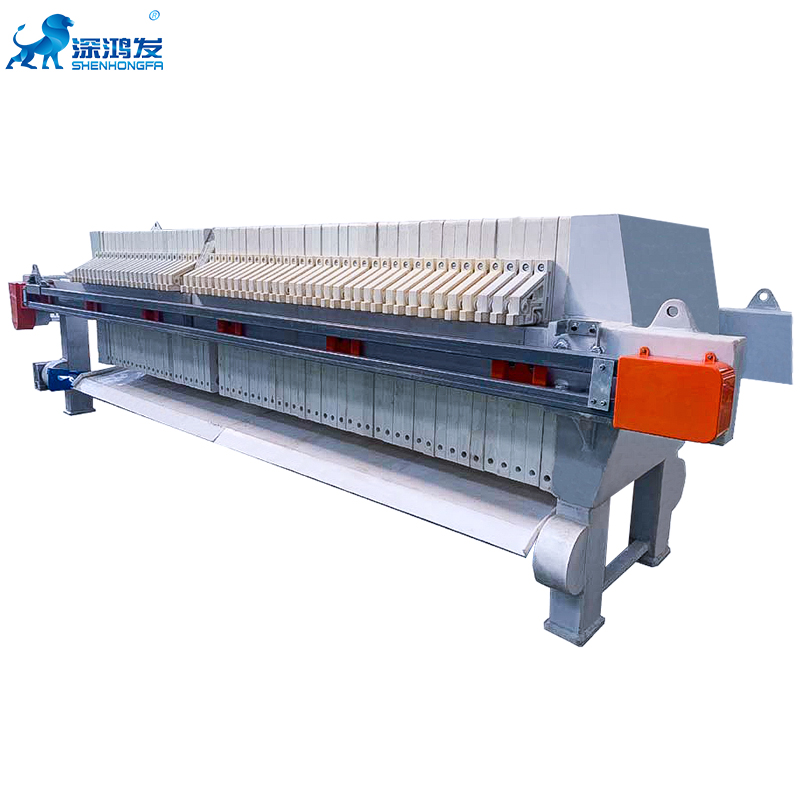

Full Automatic High Efficiency Filter Press selection

The difference between automatic filter press and ordinary filter press is that there are more automatic plate pulling system, automatic liquid turning plate, automatic cleaning filter cloth system. These automation equipment makes the filter press more intelligent and automatic in operation. The automatic filter press structure design is scientific and reasonable, high mechanical strength, stable structure, durable and easy to operate and maintain.

Why choose Shen HongFa Filter Press

We have professional team in sludge filteration which have many research staffs who have devoted themselves to the industry for more than 20 years, and our High-Efficiency Circular Filter Press for Sludge, saled all over the world.

1),Long history : our factory established in 2014,and we are the leading enterprise in filter press industry .

2),we are one of the main constitutor of press filter regulations.

3),we are a professional team which have many research staffs who have devoted themselves to the industry for more than 20 years.

4),We offer different material's filter plate according to different industry , while other providers couldn't make it .

5), Our products are sold to many companies which most of them are top500 .

6),We manufacture the filter plate ourselves , so we could guarantee its quality ,while other providers buy it from others

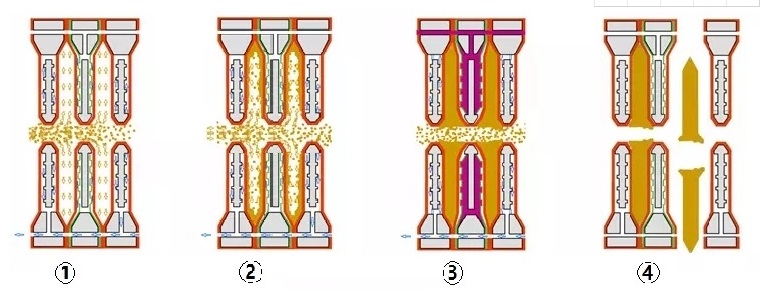

Working principle of Chamber Filter Press:

- 1. Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

- 2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

- 3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

- 4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

Product Description

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

FAQ:

1. How to buy your interested products?

You can provide us the water sources, water quality, flow rate and ground area, material requirements about your project

2. How to pay?

L/C or T/T are acceptable.Usually, 50% payment in advance, 50% payment before delivery.

3. What is the delivery time?

It depends on order quantities. Generally speaking, the delivery time will be within 1 months.

4. How to pack the products?

We use standard export package.If you have special package requirements, we will pack as you required, but the fees will be paid by customers.

5. How to install after the equipment arriving destination?

We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

6. How long is the validity?

The validity is 12 months after installation

Related Keywords