Chamber Type Automatic Pull Plate Filter Press

-

$3000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Shanghai, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 3000sets/year |

| Supply Ability: | 3000sets/year |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery |

| Certificate: | CE,RoHS |

| HS Code: | 8421291090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Shanghai,Qingdao |

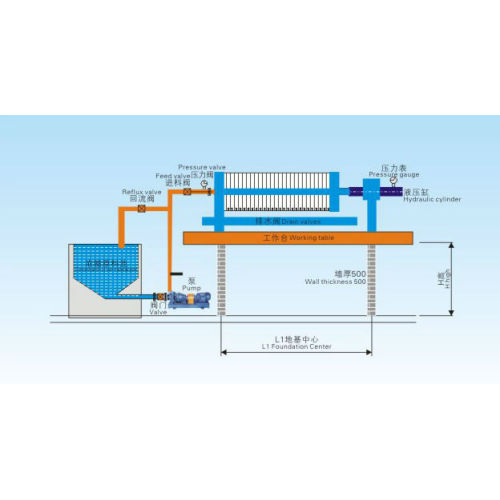

What is a chamber filter press?

Plate and frame filter press is the classic style of filter press that first appeared in the market. Later, according to needs and product technology upgrades, a series of chamber-type models gradually appeared with increasing automation. Whether it is a plate frame or a chamber type, its purpose is the same, that is, an intermittent pressurized filtration equipment, which is used in wastewater treatment that requires sludge dewatering. Now we meet many users who still can’t tell the difference between the two machines when they consult the solid-liquid separation equipment. What is the difference between the plate and frame filter press and the chamber filter press?

Plate and frame filter press consists of alternately arranged filter plates and filter frames. The plates and frames are supported on the beams by handles on both sides. There are grooves on the surface of the filter plate to support and cover the filter cloth. The pressing plate moves, and the thrust plate fixes the pressing plate and the frame, and a filter chamber is formed between the plate and the frame. There are through holes in the corners of the filter plate and the filter frame, and a complete channel is formed after assembly. The pressurized material can enter the filter chamber through this channel. After the filtrate passes through the filter cloth, it is discharged through the channel on the surface of the filter plate. After the filtration is completed, clean water can be passed through to wash the filter residue. After washing, the remaining washing liquid is sometimes removed by compressed air. Then open the pressing plate, remove the filter residue, clean the filter cloth, press the plate frame again, and so on.

The single filter plate of the chamber filter press is thicker than the plate and frame filter plate, that is, the chamber filter press consists of two identical filter plates. When the two filter plates are compressed, a filter chamber is formed to store the granular objects separated by the filter cloth. The feed hole is placed in the center of the filter plate. It is generally used in industries with a lot of granular materials such as sewage treatment, mineral processing, and coal washing. The chamber-type filter press should not cause bias pressure in each filter chamber, so the filter plate should not be damaged, the filtration speed is fast, the slag discharge is convenient, the filtration pressure is high, the liquid content of the filter cake is low, and it can withstand the maximum filtration pressure of up to 3.0Mpa. Realize automatic plate pulling and unloading, and adapt to a wider range.

Related Keywords