Dewatering of mine tailings fiilter press

-

$4000.00≥1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Min. Order:

- 1000 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Tianjin, Shenzhen, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100sets/month |

| Payment Type: | T/T,Paypal,L/C |

| Incoterm: | FOB,FAS,FCA |

| Certificate: | ISO9001 ISIO14001 CE,RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Tianjin,Shenzhen,Shanghai |

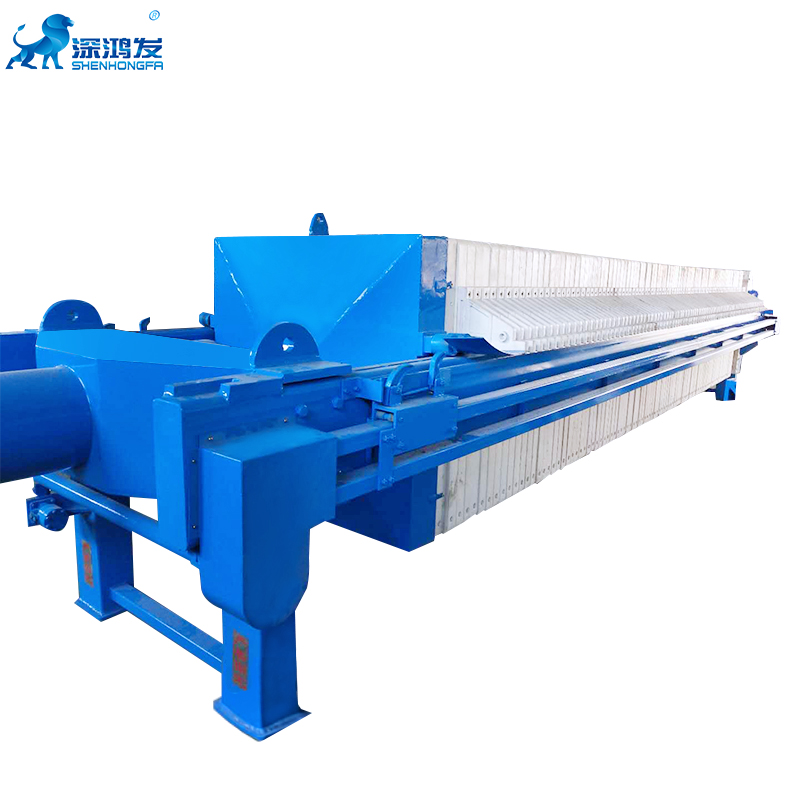

Dewatering of mine tailings fiilter press

Introduction of Sludge Dewatering Filter Press:

In recent years, dry discharge of tailings is a new tailings treatment technology gradually emerging, that is, after the tailings are treated by a series of mine tailings dewatering equipment, low water content, easy to precipitate and solidified, and can be stockpiled slag for dry storage, which not only alleviates the pressure of tailings reservoir capacity, reduces the safety hazard of tailings pond, but also increases the means of tailings reuse. It is a kind of tailings treatment technology to realize green environmental protection mine. At present, the main filters commonly used for tailings dehydration are belt filter and side filter press.

Chamber filter press is a kind of filtration equipment widely used in tailings dewatering operation at present. Its advantages lie in strong dehydration of positive pressure and high pressure, low water content of filter cake and less energy consumption. The filtrate after using the side filter press to treat the tailings is clear and transparent, which can meet the requirements of direct discharge of environmental protection waste water. The moisture content of dry slag after filtration can reach below 8%, which greatly reduces the transportation cost of tailings and the risk of tailings dry pile.

Main components of filter press:

> Frame: The steel frame acts as a clamping device for the filter plates.

> Filter Plates: A filter cake forms in the chambers between filter plates.

> Filter Cloth: A cloth filter that is attached to both sides of a filter plate. Solids build up on cloth to form a filter cake, separating liquids from solids.

Types of Filter Press according to:

> Closing mode: manual, gear drive, hydraulic;

> Filtrate flow: open flow, close flow, cake washing, non-cake washing, center feeding, corner feeding,etc..

> Filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

> Filter plate material: PP, rubber, cast iron, stainless steel;

> Filter Plate size: 320, 450, 630, 800,1000, 1250, 1500, 2000

Working principle of Chamber Filter Press:

- 1. Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

- 2. Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

- 3. When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

- 4. Once the chambers are full, the fill cycle is complete and the filter press is ready to be emptied.

Packing and Delivery

Related Keywords