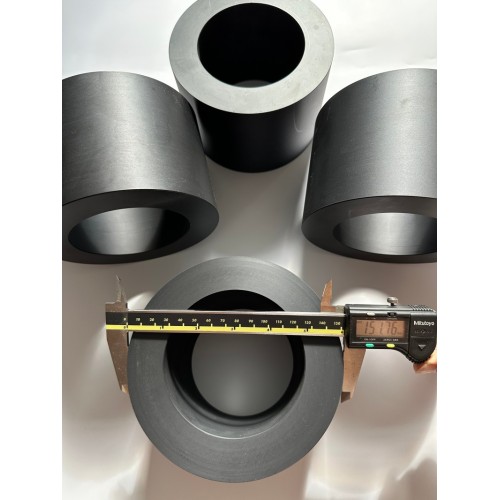

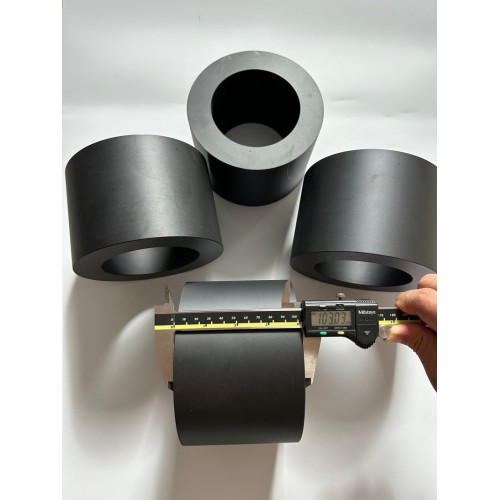

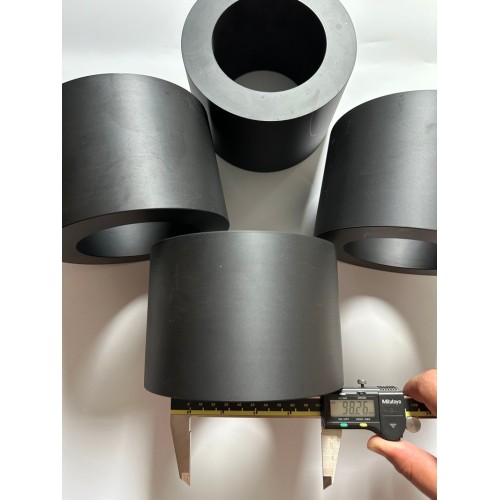

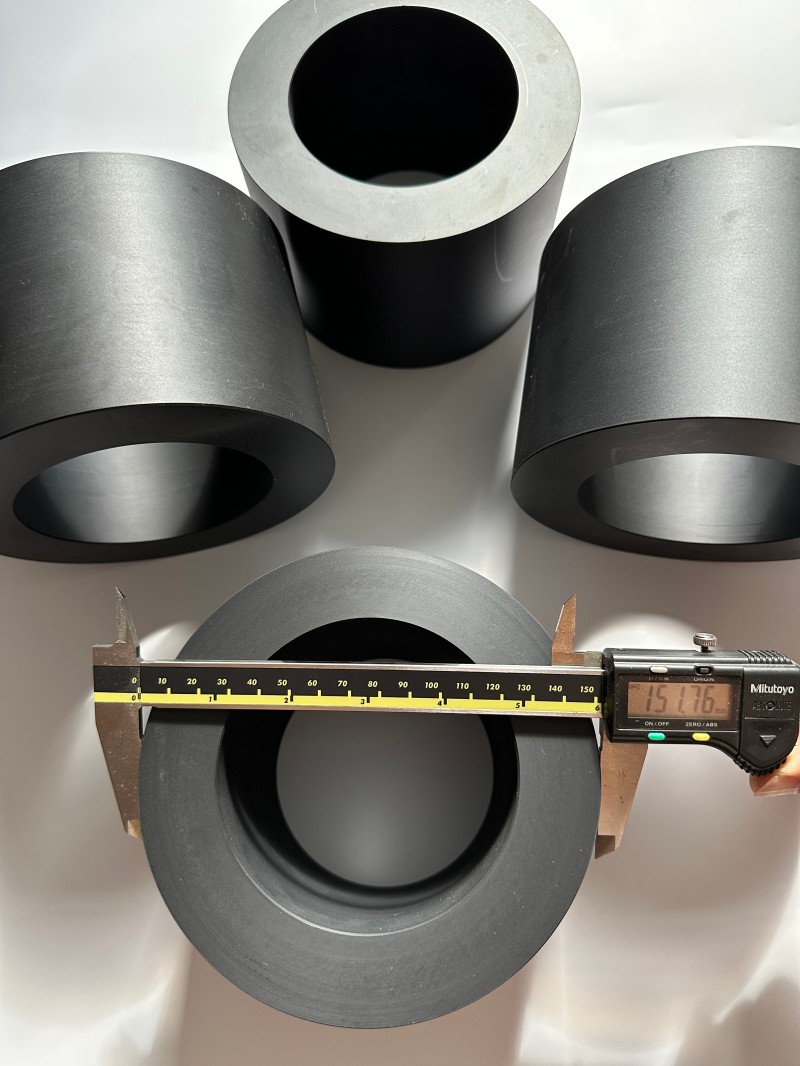

Glass-fiber-reinforced PPS 30% GF tube pipe

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Hongkong, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Hongkong,Guangzhou |

Product Description

Product Description

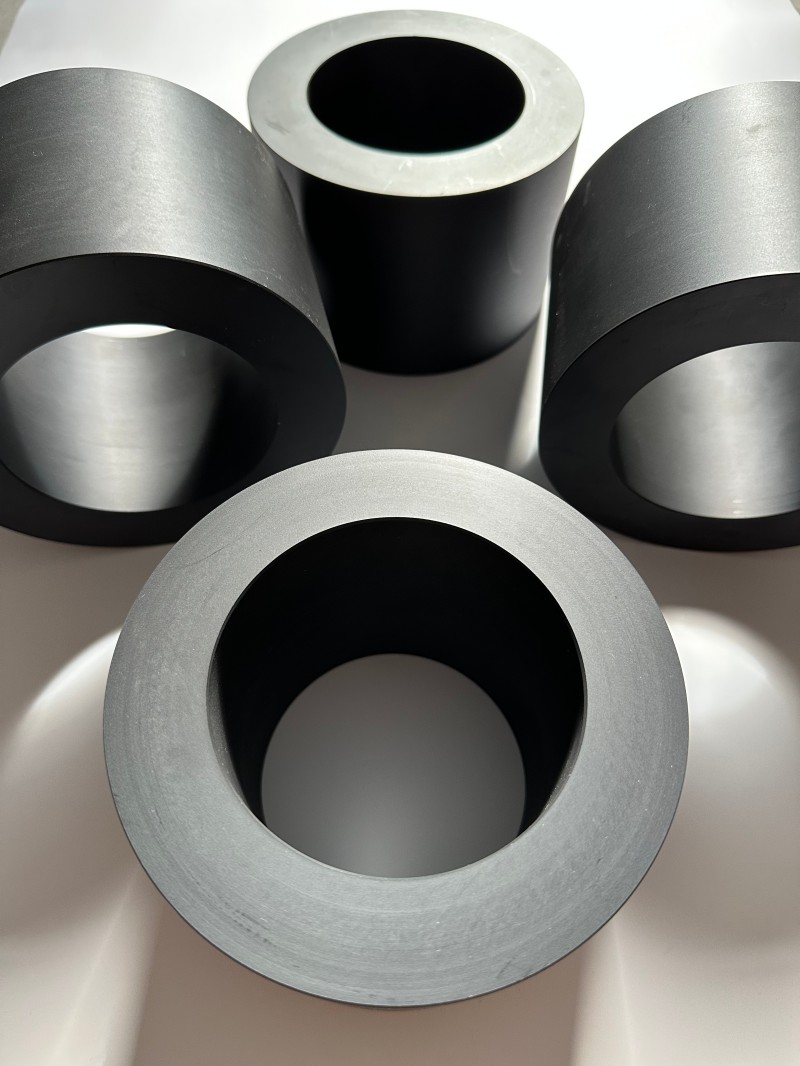

PPS plastic (polyphenylene sulfide), English name: Polyphenylenesulphide, is a thermoplastic special engineering plastic with excellent comprehensive performance. Its outstanding features include high temperature resistance, corrosion resistance, and superior mechanical properties. When dropped on the ground, the product makes a metallic sound.

Glass-fiber-reinforced PPS properties:

Thermal properties

1. High-temperature resistance

PPS has a melting point exceeding 280°C, a heat deflection temperature exceeding 260°C, and a long-term service temperature of 220–240°C. It degrades at 700°C in air and retains 40% of its weight at 1000°C in an inert gas atmosphere. Its short-term heat resistance and long-term thermal stability during continuous use both outperform current engineering plastics.

Physical Properties

1. Electrical Insulation (Especially High-Frequency Insulation)

It has a very low dielectric constant and low dielectric loss, making it an excellent electrical insulating material.

2. Strength

It has average toughness, good rigidity, but is brittle and prone to stress cracking; however, by adding glass fiber or other reinforcing materials, its impact strength, heat resistance, and other mechanical properties can be significantly improved. Suitable for manufacturing heat-resistant parts, insulating components, and parts for chemical and optical instruments.

3. Forming Performance

Good forming properties, low moisture absorption, suitable for forming after drying.

Chemical Properties

1. Excellent Flame Retardancy

Its chemical structure is highly stable and contains flame-retardant elements such as sulfur. Pure PPS can meet the UL-94 V0 rating at a thickness of 0.8 mm. It has excellent flame retardancy and is a non-flammable plastic.

2. Good radiation resistance

It is a new material unmatched by other engineering plastics. In fields such as electronics, electrical engineering, machinery, instruments, aerospace, and military applications—particularly in nuclear weapons and neutron bombs—it is the only ideal material with excellent radiation resistance.

3. Excellent chemical stability

Except for being corroded by strong oxidizing acids, it is not corroded by most acids, alkalis, or salts, exhibiting chemical stability comparable to PTFE. It is insoluble in any known organic solvents and does not exhibit cracking when exposed to general organic solvents.

Applications of Glass Fiber Reinforced PPS:

PPS has a wide range of applications, primarily in automotive components, which is expected to be the most widespread application of PPS in the future. This is because PPS not only offers outstanding continuous heat resistance and chemical resistance (to gasoline, engine oil, and other substances), but also because improvements in production efficiency (such as injection molding) have significantly reduced costs. In addition to replacing previously used metal components and phenolic resins, PPS can also replace nylon-based materials, and its application in new-use components is being accelerated. This is particularly true for components related to engine-related machinery, such as drive systems, braking systems, fuel systems, lighting systems, cooling systems, and control systems.

In SMT processes, in addition to high heat resistance, precision molding, and dimensional stability, Mingji PPS also achieves UL94 V-0-grade flame retardancy without the addition of flame retardants. These characteristics make it an ideal molding material for electrical and electronic components such as connectors.

Suitable for high-temperature electrical components with operating temperatures exceeding 200°C, as well as micro-electronic component packaging, connectors, terminals, sockets, coil frames, motor housings, electromagnetic control discs, TV high-frequency head shafts, relays, variable capacitors, fuse holders, tape recorders, and magnetic therapy devices. It is also used in precision instruments: computers, timers, tachometers, copiers, cameras, temperature sensors, and various measuring instruments' housings and components.

Home appliances: protective coatings and components for electric fans, hair dryers, curling irons, hair straighteners, hair curlers, microwave oven brackets, air conditioner compressors, coffee makers, dryers, irons, copiers, printers, electric kettle accessories, rice cookers, and more.

Mechanical industry: Specifically used in the mechanical industry for the preparation of components in high-humidity and highly corrosive environments. Used for housings, structural components, wear-resistant components, and sealing materials, including pump housings, pump wheels, valves, bearings, bearing brackets, piston rings, gears, pulleys, fans, flow meter components, flanges, universal joints, counters, and levels.

Sanitary Ware: High-temperature-resistant fittings, valves, hot/cold water switches, replacing copper components, industrial/residential water heaters, and solar water heater system components, etc.

Chemical Industry and Special Industries: PPS has excellent adhesion and corrosion resistance, making it ideal for lining chemical equipment. Acid/alkali-resistant valves, pipes, fittings, valve plates, gaskets, and metering pump housings, chemical filters or filter plates, aerospace, defense, and military applications, etc.

The core parameters of the physical properties table for PPS+30%GF (30% glass fiber reinforced polyphenylene sulfide) include: tensile strength 155-230 MPa, flexural modulus 11600-12000 MPa, heat deflection temperature 260-263°C, UL 94 flame retardant rating V-0. Specific values may vary depending on the manufacturer and testing standards.

Physical Properties

Density: 1.57–1.68 g/cm³, with glass fiber reinforcement significantly increasing material density.

Shrinkage Rate: 0.3% in the longitudinal direction and 0.9% in the transverse direction, with significant anisotropy.

Water Absorption Rate: Extremely low (0.02%–0.04%), suitable for humid environments.

Mechanical Properties

Strength and Modulus

Tensile strength: 155 MPa (Toray A503-F1) to 230 MPa (bending strength).

Bending modulus: 11,600–12,000 MPa, high rigidity.

Impact Properties

Notched Charpy impact strength: 11 kJ/m² (23°C).

Notched Charpy impact: 80 J/m (ASTM standard).

Thermal and Flame Retardant Properties

Heat Deflection Temperature (HDT): 260–263°C at 1.8 MPa load, excellent high-temperature resistance.

Flame Retardant Rating: UL 94 V-0 (0.35 mm thickness), meets stringent fire safety requirements.

Related Keywords

Related Keywords