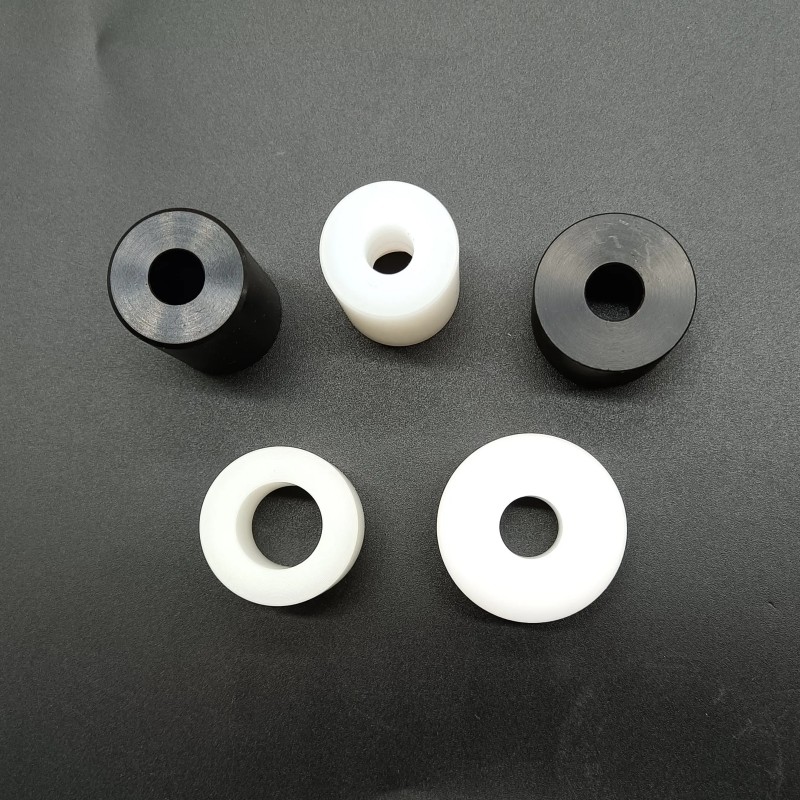

Mc Cast Nylon Tube Nylon Round Rod

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

Poured nylon tubing is a type of nylon tubing made through the casting process, offering a variety of excellent properties and application scenarios.

Definition and Manufacturing Process

Cast nylon tubing is made by injecting molten nylon material into a mold through a polymerization reaction and subsequent processing. Specifically, molten lactam monomer is injected into a preheated mold to form a tough solid blank through polymerization, and then the intended product is processed through related processes.

Performance Characteristics

Abrasion resistance and corrosion resistance: cast nylon tube has good abrasion resistance and corrosion resistance, suitable for all kinds of mechanical equipment and chemical pipeline and other environments

Temperature resistance: it can work in the environment of -40 to 100 degrees Celsius, showing good temperature resistance performance

Mechanical properties: it has high strength, high stiffness and high hardness, suitable for occasions that need to bear heavy loads

Processing performance: can be welded, turned, drilled and other processing, suitable for a variety of machinery manufacturing and home improvement scenarios

Application Scenario

Automobile industry: In the automobile piping system, cast nylon tube is used to transport gas and liquid to ensure safety, energy saving and environmental protection.

Mechanical equipment: due to its high strength and wear resistance, it is widely used in various mechanical equipment, such as gears, bearings and other parts of the manufacturing

Chemical industry: in chemical piping, cast nylon tube can withstand various corrosive media, to ensure the smooth progress of production

Difference between cast nylon and extruded nylon

I. Different production methods of cast nylon and extruded nylon

Cast nylon is manufactured by casting nylon resin into molds. Often, this material is called nylon 6 or nylon 66 because it is made from caprolactam or hexalactam. The advantages of cast nylon are its high strength and rigidity, and its ability to resist high temperatures and corrosion, which is why it is widely used in the manufacture of machine parts and automotive components.

Extruded nylon is produced by extruding nylon resin to form tubes, rods, sheets or filaments. Extruded nylon is mainly used for insulating materials, zippers, cables, tapes, brushes and so on.

Second, pouring nylon and extruded nylon physical properties of different

Due to the different production methods of poured nylon and extruded nylon, there are differences in their physical properties. The density of poured nylon is higher, the melting point is higher, the strength and hardness are higher than that of extruded nylon. While extruded nylon has lower density, good flexibility and good resistance to bending and twisting.

Third, the use of poured nylon and extruded nylon is different.

Pouring nylon is widely used in the manufacture of mechanical parts and automobile parts, electrical insulation materials due to its high strength, high heat resistance and high corrosion resistance. In addition, cast nylon is also used in the manufacture of various rods, tubes, shafts, gears, machine tool guides, propellers and so on.

Extruded nylon has good flexibility and good bending resistance, so it is widely used in the manufacture of various insulating materials, wires and cables, brushes, zippers and other products. In addition, extruded nylon can be used to produce plastic bags, plastic bottles and so on.

[Conclusion

In summary, although both cast nylon and extruded nylon belong to nylon materials, there are great differences in their production methods, physical properties and uses. For the production of mechanical parts, automobile parts, electrical insulation materials and other requirements of high strength and high heat resistance, cast nylon is a very ideal material. For the production of hoses, tapes, zippers, brushes and other products with good flexibility and bending resistance, extruded nylon is more suitable.

Related Keywords

Related Keywords