Radel®polyphenylsulfone (PPSU) sheet rod

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Air, Express, Land

- Port:

- SHENZHEN, GUANGZHOU, HONGKONG

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU,DDP |

| Transportation: | Ocean,Air,Express,Land |

| Port: | SHENZHEN,GUANGZHOU,HONGKONG |

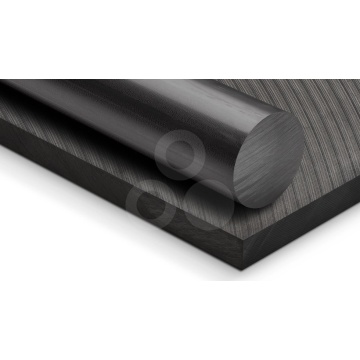

PPSU material (chemically known as polyphenylsulfone) is manufactured by Ensinger in standard stock shapes for machining, and is most often extruded in sheet and rod using Radel® PPSU polymer.

PPSU plastic is an amorphous material, which has a high glass transition temperature and low moisture absorption. Furthermore, PPSU material has better impact strength and chemical resistance than PSU and PES from the polysulfone group. Apart from these characteristics, PPSU polymer can withstand sterilisation with superheated steam better than other members of this group of polymers, and is resistant to detergents and disinfectants.

Radel®R PPSU Polyphenylsulfone an amorphous high performance thermoplastic offering better impact and chemical resistance than polysulfone (Udel® ) or polyetherimide(ULTEM®)

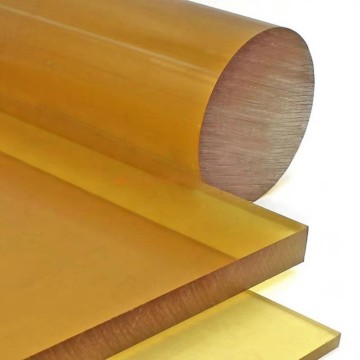

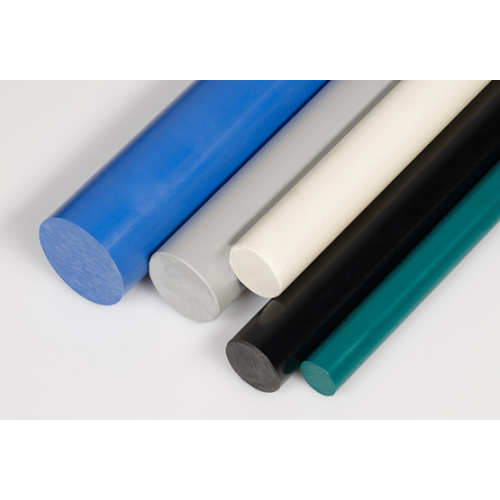

Radel® polyphenylsulfone (PPSU) delivers the highest performance of the sulfone polymers.Radel®PPSU offers impact strength similar to polycarbonate (PC) and better chemical resistance than polyetherimide (ULTEM™ PEI). It excels in high heat and humidity environments and provides operating temperatures around 200°C (392°F) and inherent flame retardant properties. Radel®R is available sheet, rod, tube, film, custom profile and molded and machined parts, in amber (translucent), natural (bone white), and custom colors.

PPSU MATERIAL PROPERTIES AND SPECIFICATIONS

PPSU plastics offer:

- High operating temperature (180°C)

- Good chemical compatibility

- Excellent resistance to hydrolysis (suitable for repetitive steam sterilisation)

- High rigidity over a wide range of temperatures

- Very high impact strength

- High dimensional stability

- Very good resistance against high energy radiation (gamma and X-rays)

- Good electrical insulating properties

- Favourable dielectric characteristics

Modifications to PPSU Radel®

are manufactured under the brand name TECASON P and offer the following PPSU modifications:

- TECASON P - PPSU for industrial applications

- TECASON P MT - PPSU for medical use, biocompatible, different colours

- TECASON P MT XRO - PPSU for medical use, specially modified to be x-ray opaque, biocompatible

Polyphenylsulfone (PPSU) sheet rod application:

- Food Equipment and Dairy Connectors

- Electronics Manufacturing and Fixtures

- Medical Devices Handles and Fixtures

- Food Service Trays

- Aircraft Interior Parts

Related Keywords